Low-temperature hyperelastic Ti-Ni-Cu-Y-Hf shape memory alloy and preparation method thereof

A ti-ni-cu-y-hf, memory alloy technology, applied in the field of low-temperature superelastic Ti-Ni-Cu-Y-Hf shape memory alloy and its preparation, can solve the problem of low-temperature superelasticity, phase transition temperature Advanced problems, to achieve the effect of improving the mechanical properties of alloys, good mechanical properties, improving oxidation resistance and memory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using high-purity metal Ti, Ni, Cu, Y, and Hf as raw materials, after cleaning, the atomic ratio of 39% Ti, 44% Ni, 6% Cu, 1% Y and 10% Hf is used as alloy 1 , put the raw material in the vacuum electric arc furnace, vacuumize to 8.5*10 -3Below Pa, refill argon gas to -0.05MPa and then strike the arc, control the melting current at 100-300A, turn on the magnetic stirring power, ensure that all metals are completely melted together, and then turn off the power. The obtained alloy ingot is turned over with a manipulator, and then smelted repeatedly 6 times to make the composition of the raw material uniform; the obtained alloy is cut into small pieces by wire, placed in a vacuum heat treatment furnace and evacuated to -0.05MPa, and then filled with argon. After homogenization at 900°C for 2h, it was quickly quenched in an ice-water mixture to obtain a Ti-Ni-Cu-Y-Hf shape memory alloy.

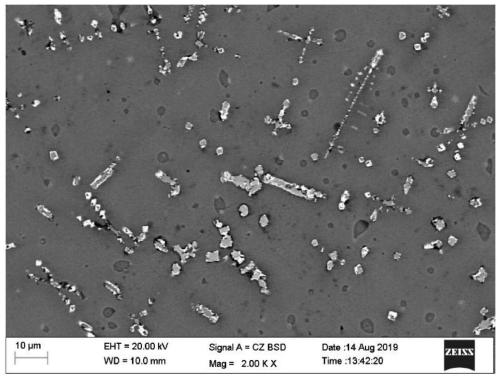

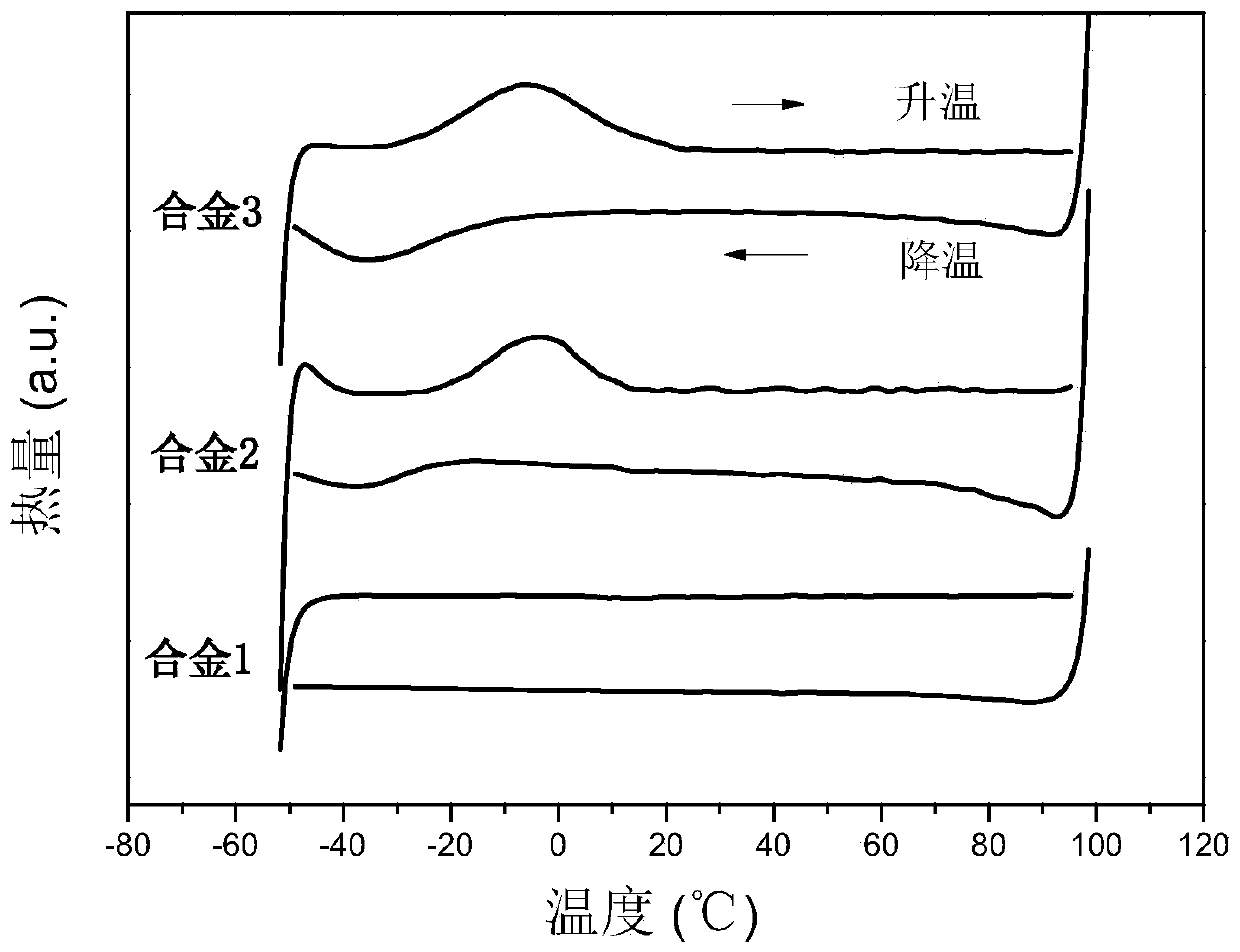

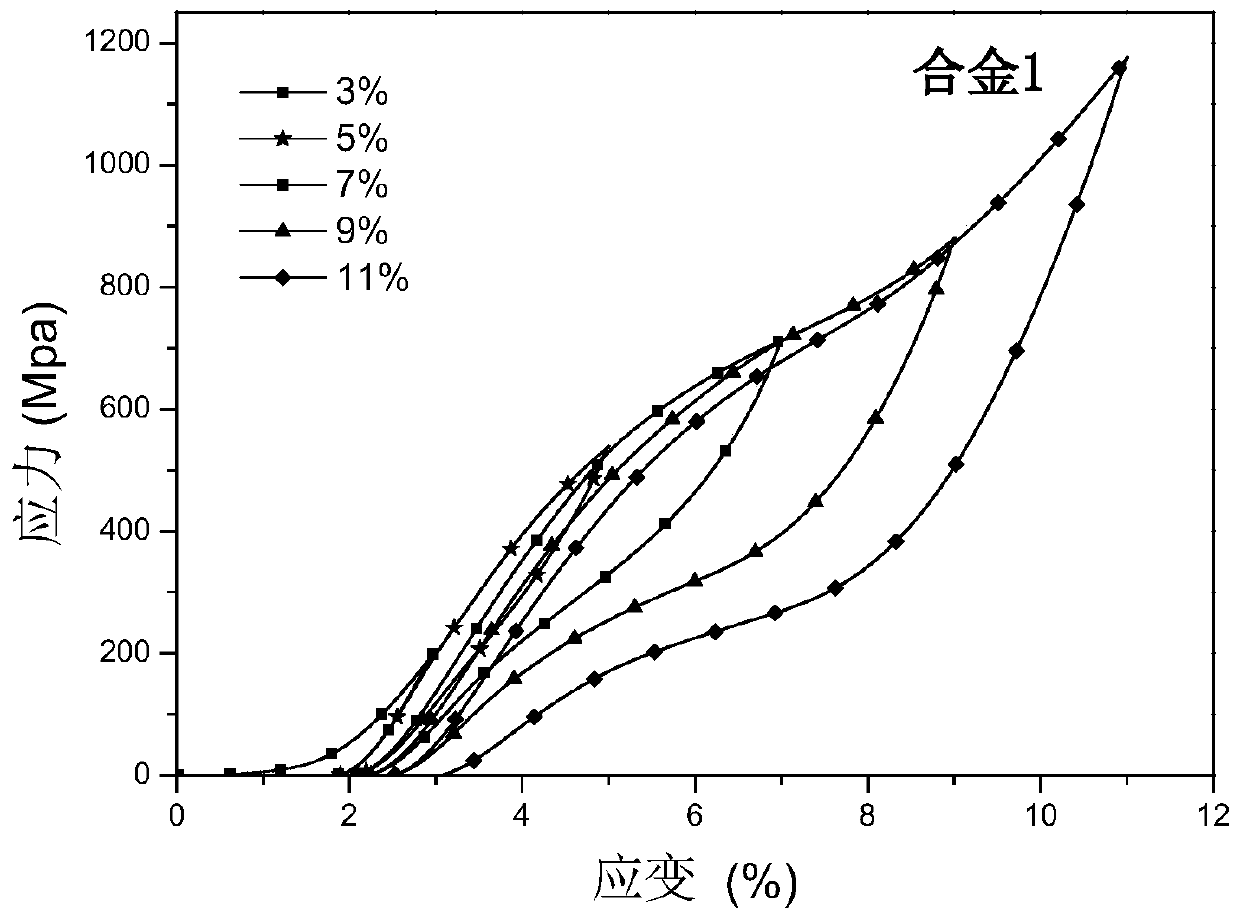

[0040] The microstructure photo of gained alloy 1 is as follows figure 1 Shown, the ...

Embodiment 2

[0042] Using high-purity metals Ti, Ni, Cu, Y, and Hf as raw materials, after cleaning, the atomic ratio of 43% Ti, 44% Ni, 6% Cu, 1% Y and 6% Hf is the alloy 2 , put the raw material in the vacuum electric arc furnace, vacuumize to 8.5*10 -3 Below Pa, refill argon gas to -0.05MPa and then strike the arc, control the melting current at 100-300A, turn on the magnetic stirring power, ensure that all metals are completely melted together, and then turn off the power. The obtained alloy ingot is turned over with a manipulator, and then smelted repeatedly 6 times to make the composition of the raw material uniform; the obtained alloy is cut into small pieces by wire, placed in a vacuum heat treatment furnace and evacuated to -0.05MPa, and then filled with argon. After homogenization at 900°C for 2h, it was quickly quenched in an ice-water mixture to obtain a Ti-Ni-Cu-Y-Hf shape memory alloy.

[0043] The microstructure photograph of gained alloy 2 is as Figure 5 As shown, the tr...

Embodiment 3

[0045] Using high-purity metals Ti, Ni, Cu, Y, and Hf as raw materials, after cleaning, the atomic ratio of 47% Ti, 44% Ni, 6% Cu, 1% Y and 2% Hf is used as alloy 3, and the raw materials are placed in In the vacuum electric arc furnace, vacuumize to 8.5*10 -3 Below Pa, refill argon gas to -0.05MPa and then strike the arc, control the melting current at 100-300A to ensure that all metals are completely melted together, and then turn off the power. The obtained alloy ingot is turned over with a manipulator, and then smelted repeatedly 6 times to make the composition of the raw material uniform; the obtained alloy is cut into small pieces by wire, placed in a vacuum heat treatment furnace and evacuated to -0.05MPa, and then filled with argon. After homogenization treatment at 900° C. for 2 hours, the Ti-Ni-Cu-Y-Hf shape memory alloy was obtained by quenching and cooling in ice water.

[0046] The microstructure photograph of gained alloy 3 is as Figure 9 As shown, the transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com