Refrigerant compressor

a refrigerant compressor and compressor technology, applied in the direction of positive displacement liquid engines, liquid fuel engine components, positive displacement pump components, etc., can solve the problems of undesirable motor cooling, internal heat of the compressor housing due to the compressed refrigerant in the discharge muffler, etc., to improve the efficiency of the refrigerant compressor and reduce the absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

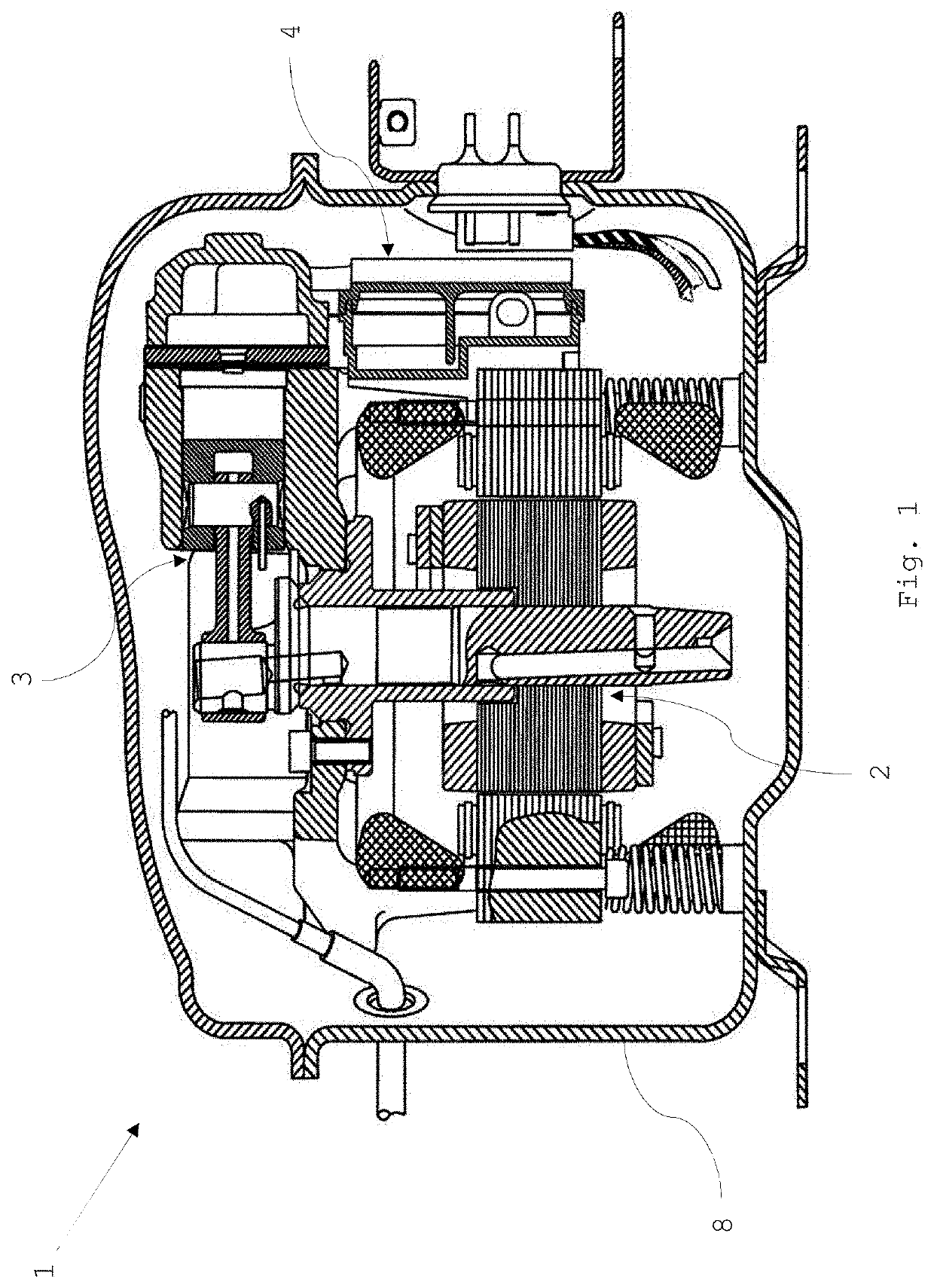

[0048]FIG. 1 shows a sectional view of a known refrigerant compressor 1. The refrigerant compressor 1 comprises a compressor housing 8, a drive unit 2, a piston / cylinder unit 3 in which the cyclical compression of a refrigerant takes place, and at least one sound-damping unit 4.

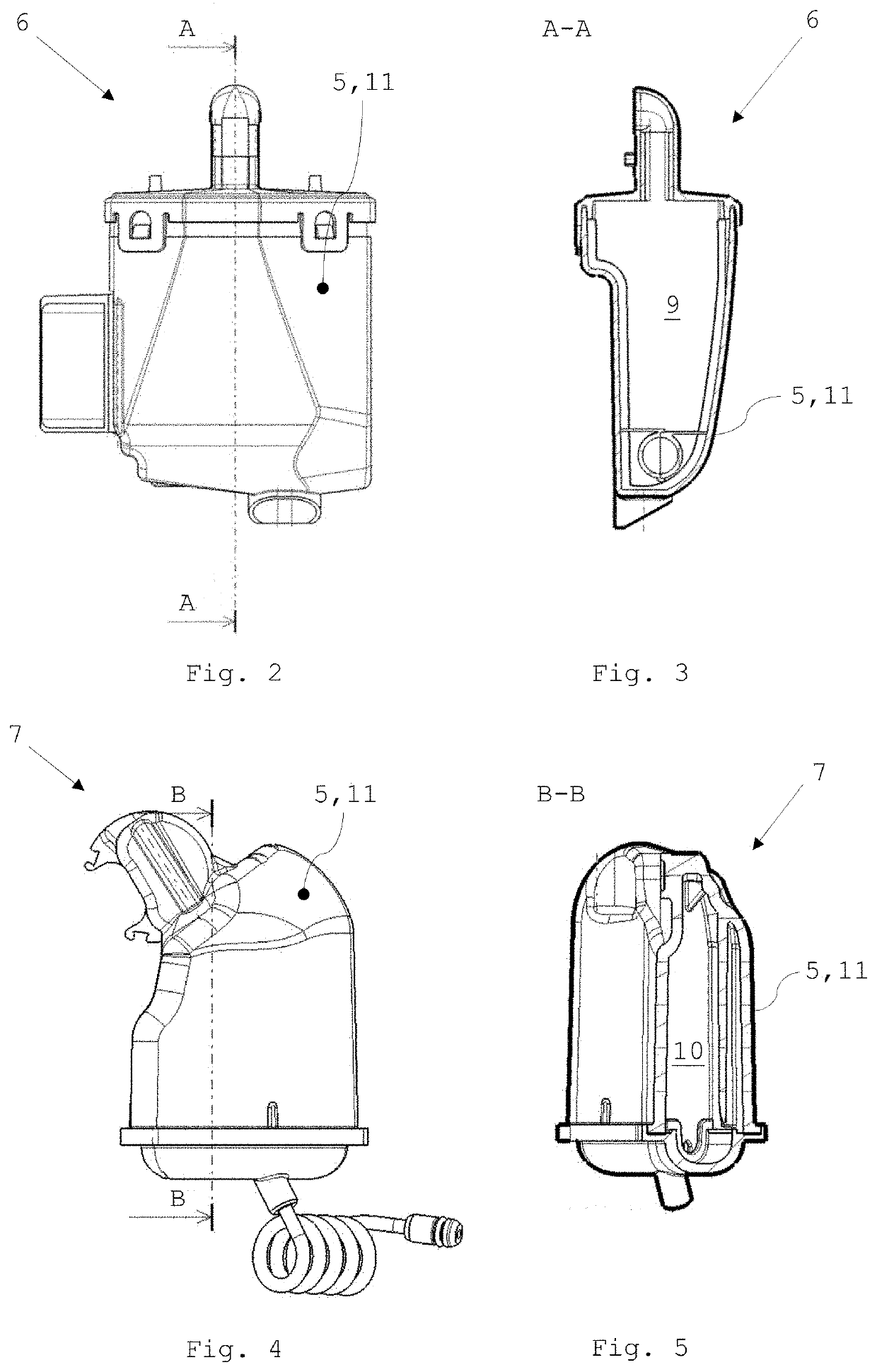

[0049]The at least one sound-damping unit 4 can be a suction muffler 6 and / or a discharge muffler 7. The suction muffler 6 is arranged upstream of the piston / cylinder unit 3 in the direction of flow of the refrigerant, whereas the discharge muffler 7 is located downstream of the piston / cylinder unit 3 in the direction of flow of the refrigerant.

[0050]On the path between the entry of the refrigerant into the compressor housing 8 and the intake valve of the piston / cylinder unit 3, there occurs, as mentioned previously, an undesired heating of the refrigerant. This can be attributed to the heating of the interior of the compressor housing 8, which occurs, among other things, as a result of the compressed refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com