Sawtooth-shaped conductive silicone rubber nano composite material as well as preparation method and application thereof

A rubber nano, composite material technology, applied in additive processing, electrical components, magnetic field/electric field shielding, etc., can solve the problems of limited application, poor electromagnetic shielding effect of thin films, etc., to achieve high electromagnetic shielding efficiency, excellent electromagnetic shielding efficiency , the effect of expanding the possibility of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

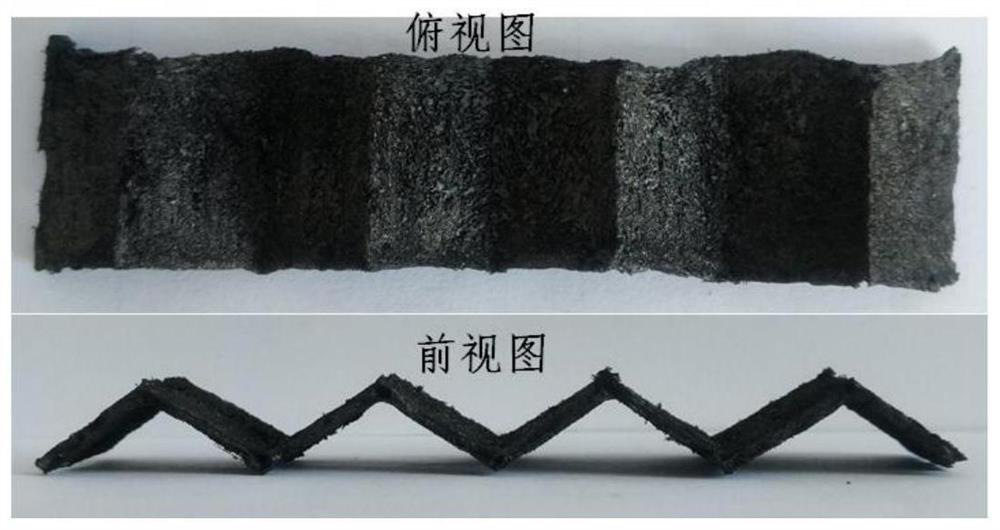

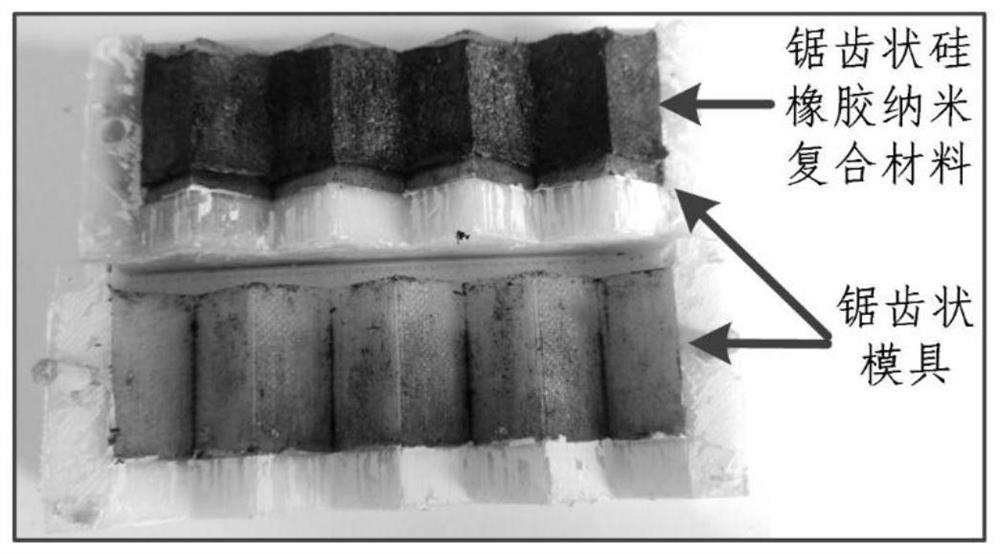

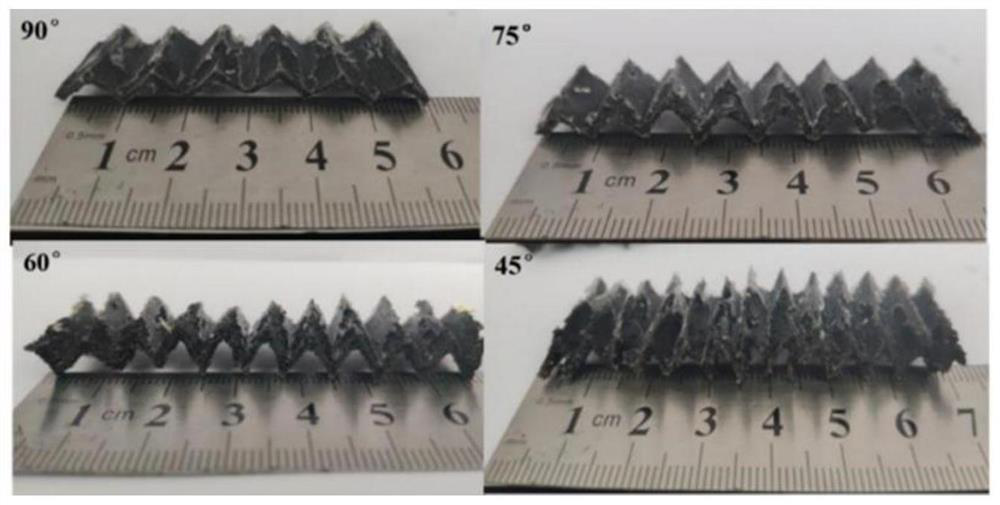

[0037] Using PMMA as a raw material, a 3D fused deposition (FDM) molding technique is used to print a serrated mold. The serrated mold contains a serrated cavity. In this embodiment, the included angle of each serration in the cavity of the mold is 90°. The mold was soaked in an ethanol solution of 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane (0.5 wt %) for 2 h and placed in a 60° C. oven to dry (30 min) and then closed. A hydrophobic coating is formed on the surface of the mold, which reduces the adhesion between the material and the inner surface of the mold and facilitates demoulding in the subsequent steps.

[0038] In order to simply compare the effect of the zigzag angle on the material properties, in Example 1, the subsequent zigzag-shaped three-dimensional conductive gel network and silicone rubber backfilling / curing steps (material ratio) are the same as those in Comparative Example 1. The detailed preparation process and parameters As follows:

[0039] 1) Synthesis ...

Embodiment 2

[0048] Using polycarbonate (PC) as a raw material, a serrated mold is obtained by 3D printing technology. The serrated mold contains a serrated inner cavity. In this embodiment, the included angle of each serration in the inner cavity of the mold is 75°. The mold was soaked in an ethanol solution of 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane (0.5 wt %) for 2 h and placed in a 60° C. oven to dry (30 min) and then closed.

[0049] 1) Synthesis of 3D zigzag silver nanowires / MXene conductive aerogel (with an included angle of 75°)

[0050] a) MXene (Ti 3 C 2 T x ) preparation of aqueous dispersions

[0051] Add 20ml HCl (9M) and 1g LiF to the PTFE vial, stir at 800r / min for 30min, fully dissolve, and slowly add 1g Ti 3 AlC 2 , 35 ℃ reaction 24h. The product was washed by centrifugation to pH ≥ 6. Then ultrasonic peeling for 1h, centrifugation (3500r / min, 30min) to take the upper layer is the required MXene (Ti 3 C 2 T x ), which was configured into a certain concentrat...

Embodiment 3

[0058] Using acrylonitrile-butadiene-styrene copolymer (ABS resin) as raw material, 3D melt printing is used to obtain a serrated mold with an included angle of 60°. The serrated mold contains a serrated inner cavity. The included angle of each serration in the cavity is 60°. The mold was placed in an ethanol solution (0.5 wt %) of 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane for 2 hours, and then dried in an oven at 60° C. and then closed.

[0059] 1) Synthesis of 3D zigzag polyaniline nanowires / MXene aerogel (with an included angle of 60°)

[0060] The preparation method of the two-dimensional MXene nanosheet aqueous dispersion in this example is the same as the steps in Example 2. The polyaniline nanowire aqueous dispersion is mixed with the synthesized MXene nanosheet aqueous dispersion (the mass ratio of the two is 2 / 4; the above-mentioned mixed solution is injected into the zigzag mold of the above-mentioned ABS (the included angle is 60°) , and then placed in a closed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com