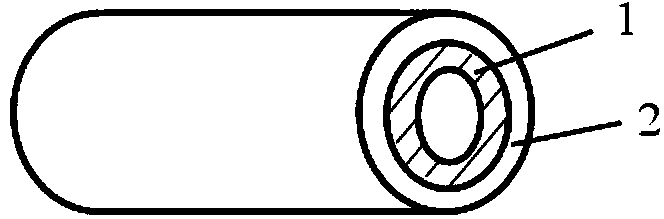

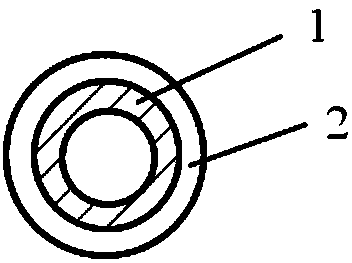

Carbon nanotube/polypyrrole composite sponge and preparation method thereof

A carbon nanotube, composite sponge technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve uniform thickness, excellent microstructure, and ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Set up a chemical vapor deposition reaction furnace, put a quartz substrate in the quartz reaction chamber, and heat it, and at the same time pass 800mL / min argon gas to exhaust the air in the reaction chamber; when the quartz substrate reaches 860 ° C, adjust the argon gas The flow rate is 2000mL / min, 300mL / min hydrogen gas is introduced, 60mg / mL ferrocene / dichlorobenzene carbon source solution is introduced into the reaction chamber, and the feed rate is 0.13mL / min; after 4 hours of reaction, at 100mL / min Under the protection of argon gas, it was cooled with the furnace, and the carbon nanotube sponge in the form of a block was collected on the quartz substrate.

[0035] 2) Cut out 0.5×0.5×0.5cm 3 Submerge the carbon nanotube sponge block in 0.5mol / L pyrrole / acetone solution. After soaking for 30 minutes, the pyrrole is absorbed into the sponge block, and it is taken out for use.

[0036] 3) Set up an electrochemical workstation for the electrochemical polymerizat...

Embodiment 2

[0039]The difference between this example and Example 1 is that in step 3), a sodium perchlorate solution with a concentration of 0.2 mol / L is used. The prepared composite sponge product has a polypyrrole content of 50.3wt%. Figure 3(a) is a comparison of the compression curves of carbon nanotube / polypyrrole composite sponge and carbon nanotube sponge. It can be seen that under the same compression strain, the stress value of the composite sponge increases significantly, and the mechanical properties are enhanced. Figure 3(b) is the compression cycle curve of carbon nanotube / polypyrrole composite sponge, and the compression strain is 50%. From the cycle curve, it can be seen that the composite sponge has good elasticity and structural stability under repeated compression conditions.

Embodiment 3

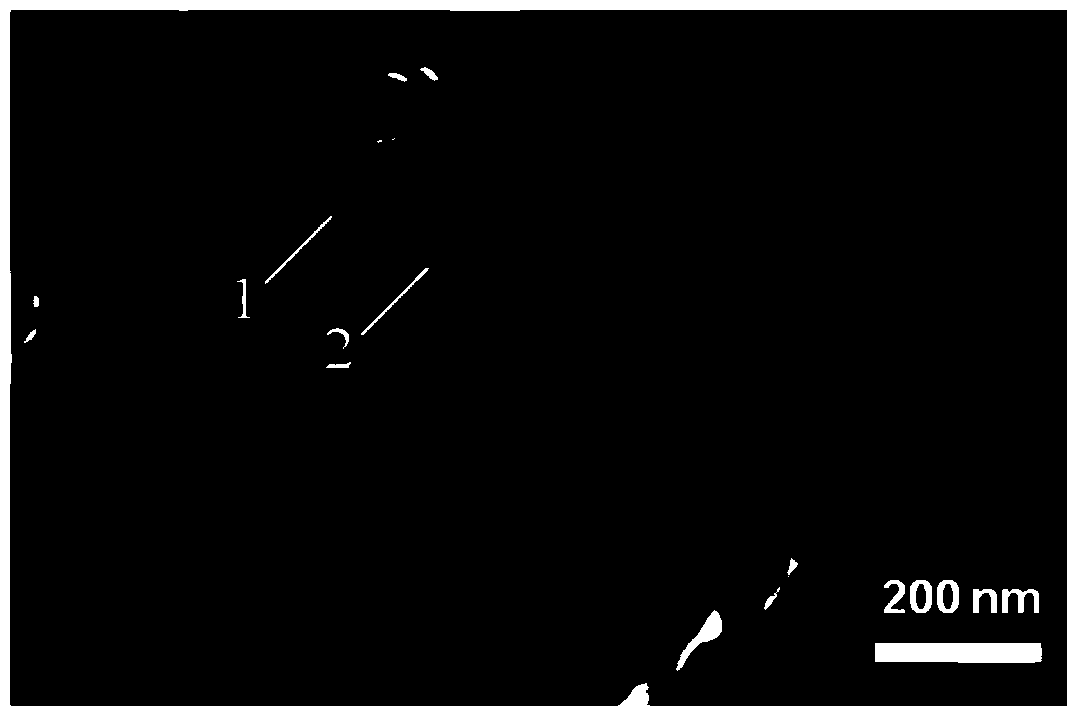

[0041] The difference between this example and Example 1 is that in step 2), a 0.1 mol / L pyrrole / acetone solution is used. The prepared composite sponge product has a polypyrrole content of 18.2wt%. Figure 4 It is a transmission electron micrograph of the composite sponge, and it can be measured from the figure that the thickness of the polypyrrole layer in the composite sponge is 5-8nm, which is obviously smaller than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com