Skin touch sensor and manufacturing method thereof

A tactile sensor, sensor technology, applied in instruments, measuring devices, measuring forces, etc., can solve problems such as the inability to meet the needs of smart wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with embodiment.

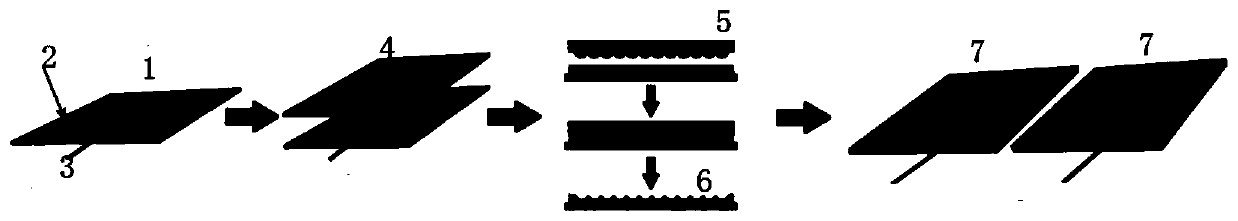

[0035] figure 1 The illustrated embodiment shows the manufacturing process of the skin tactile sensor involved in the present invention, including the following steps:

[0036] (1) Cut the natural cellulose fabric and / or the regenerated cellulose fabric into cloth pieces 1 of suitable size, and iron them flat;

[0037] (2) Draw a square on the cloth piece 1;

[0038] (3) Carry a smaller square along the inner circle of the square with silver-plated yarn 2;

[0039] (4) The silver-plated yarn reserves a length of 10 cm on one side of the cloth piece 1 as the wire 3;

[0040] (5) Apply conductive composite material 4 to the front of the cloth block 1 (the side without the silver-plated yarn wire 3), then cover with a semicircular raised part, a mold 5 with a radius of about 1mm, and compact it ;

[0041] (6) After forming by natural vulcanization at room temperature for 24 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com