Apparatus and method for testing permeability of porous material

A porous material and permeability technology, applied in the field of material testing, can solve problems such as less consideration of permeability performance and far difference in permeability compatibility of natural bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

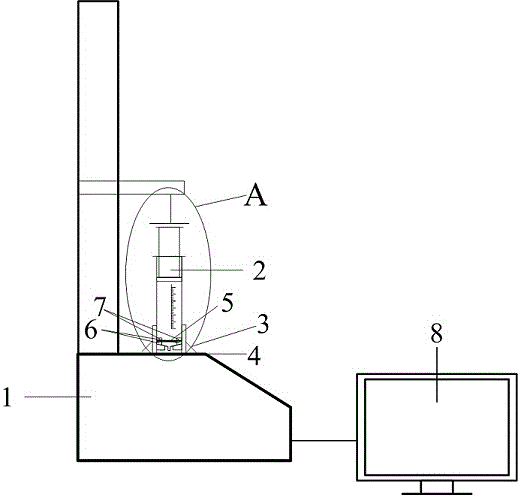

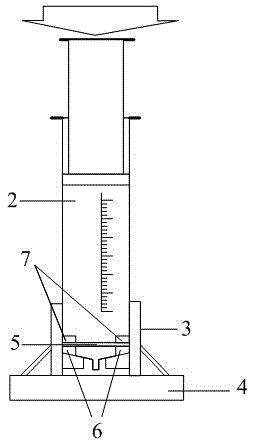

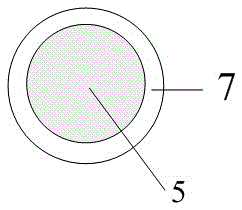

[0047] Embodiment 1: the test of artificial bone permeability

[0048] (1) Using a 150ml syringe with an inner diameter of D=40mm, the artificial bone test piece is ground into a thin slice with a diameter of d=30mm and a thickness of 5mm, and put it between the first and second sealing pads of the syringe and compact it. Then fill with water and evacuate the air, record the original height h of the water column 0 . Then use a material testing machine to pressurize, set the pressure to 10N, and keep it for 2 minutes, and observe the drop height z of the water column 0 , and record, in order to reduce the error, adopt continuous test, pressure increment method, increase 5N each time, keep the same time for 2 minutes. Take the viscosity of water η=10 -3 Pa·s. Then repeat 5 times, and record the height of each liquid level drop. Fill in Form 1 below:

[0049] Table 1: Example 1—the test data form of artificial bone permeability

[0050]

[0051] (2) Then bring into the ...

Embodiment 2

[0052] Embodiment 2: the test of porous titanium metal permeability

[0053] (1) Using a 150ml syringe with an inner diameter of D = 30mm, the porous titanium metal specimen is ground into a thin slice with a diameter of d = 25mm and a thickness of 10mm, and put it between the first sealing pad and the second sealing pad of the syringe and compact it. Then fill with water and evacuate the air, record the original height h of the water column 0. Then use a material testing machine to pressurize, set the pressure to 50N, and keep it for 5 minutes, and observe the drop height z of the water column 0 , and record, in order to reduce the error, adopt continuous test, pressure increment method, increase 50N each time, keep the same time for 5 minutes. Take the viscosity of water η=10 -3 Pa·s. Then repeat 5 times, and record the height of each liquid level drop. Fill in Form 2 below:

[0054] Table 2: Example 2 - test data table of porous titanium metal

[0055]

[0056] ...

Embodiment 3

[0058] Embodiment 3: the permeability test of aluminum foam material

[0059] (1) Using a 200ml syringe with an inner diameter of D = 45mm, the artificial bone specimen is ground into a thin slice with a diameter of d = 35mm and a thickness of 40mm, and put it between the first and second sealing pads of the syringe and compact it. Then fill with water and evacuate the air, record the original height h of the water column 0 . Then use a material testing machine to pressurize, set the pressure to 100N, and keep it for 10 minutes, and observe the drop height z of the water column 0 , and record, in order to reduce the error, adopt continuous test, pressure increment method, increase 100N each time, keep the same time for 10 minutes. Take the viscosity of water η=10 -3 Pa·s. Then repeat 5 times, and record the height of each liquid level drop. Fill in Form 3 below:

[0060] Table 3: Example 3——Test data form of aluminum foam material

[0061]

[0062] (2) Finally, bring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com