Tensile test clamp for high-pressure hydrogen environment material testing machine

A technology of material testing machine and tensile test, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as difficulty in automatic alignment, cumbersome and time-consuming installation, large and complex structure, etc., to improve accuracy and fast installation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

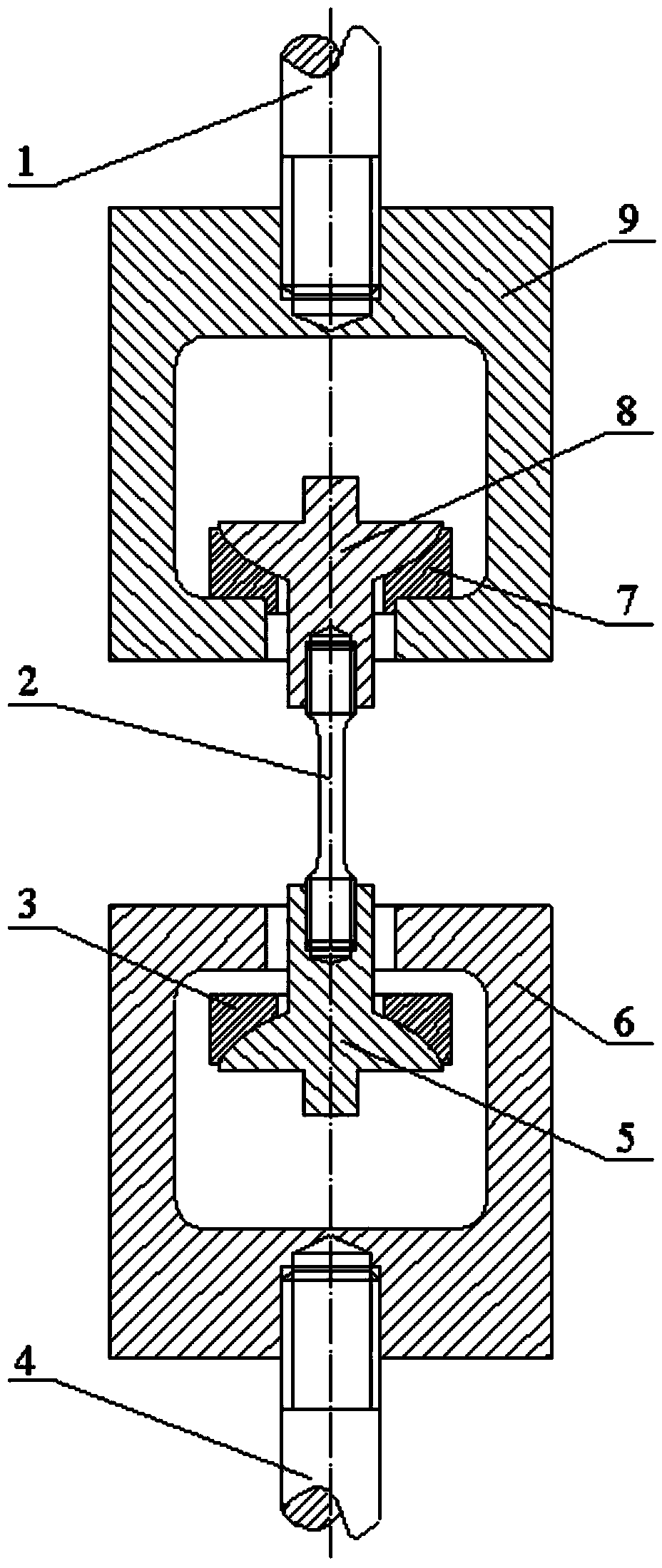

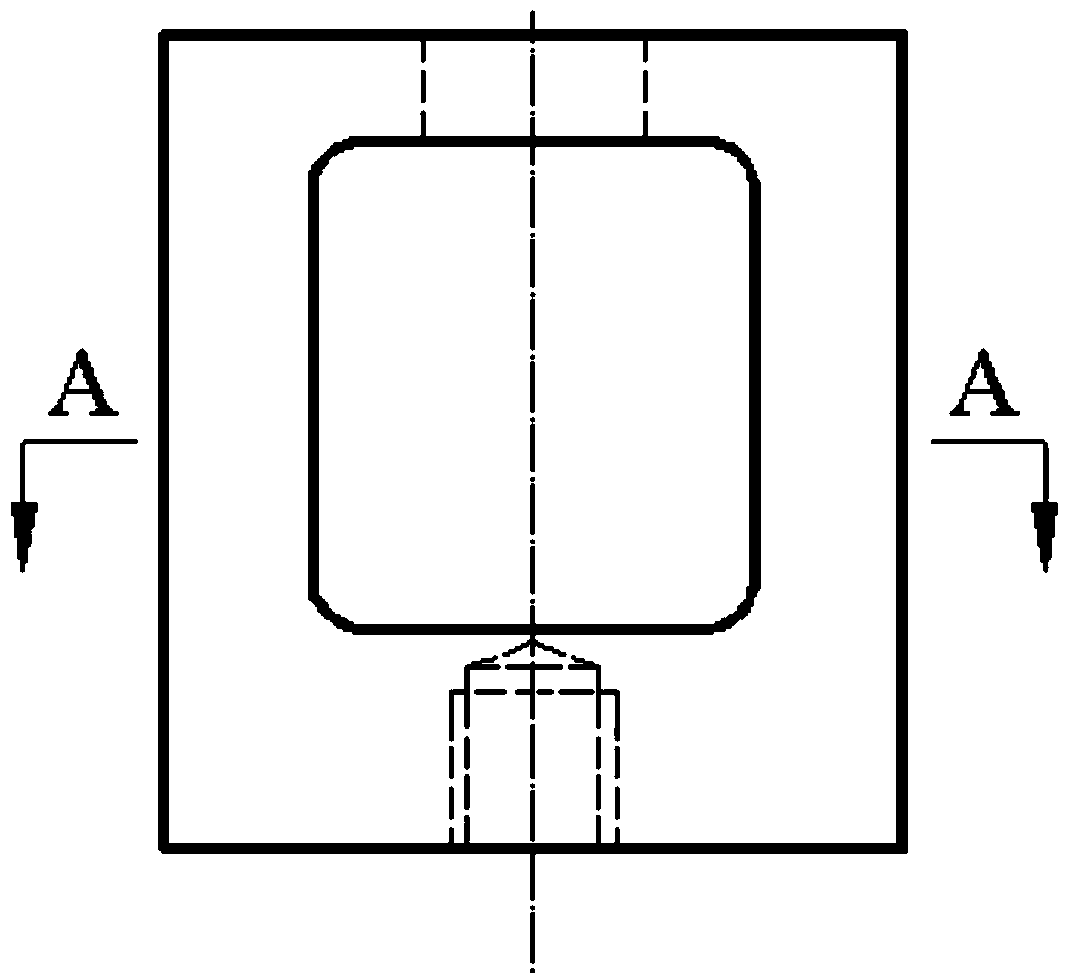

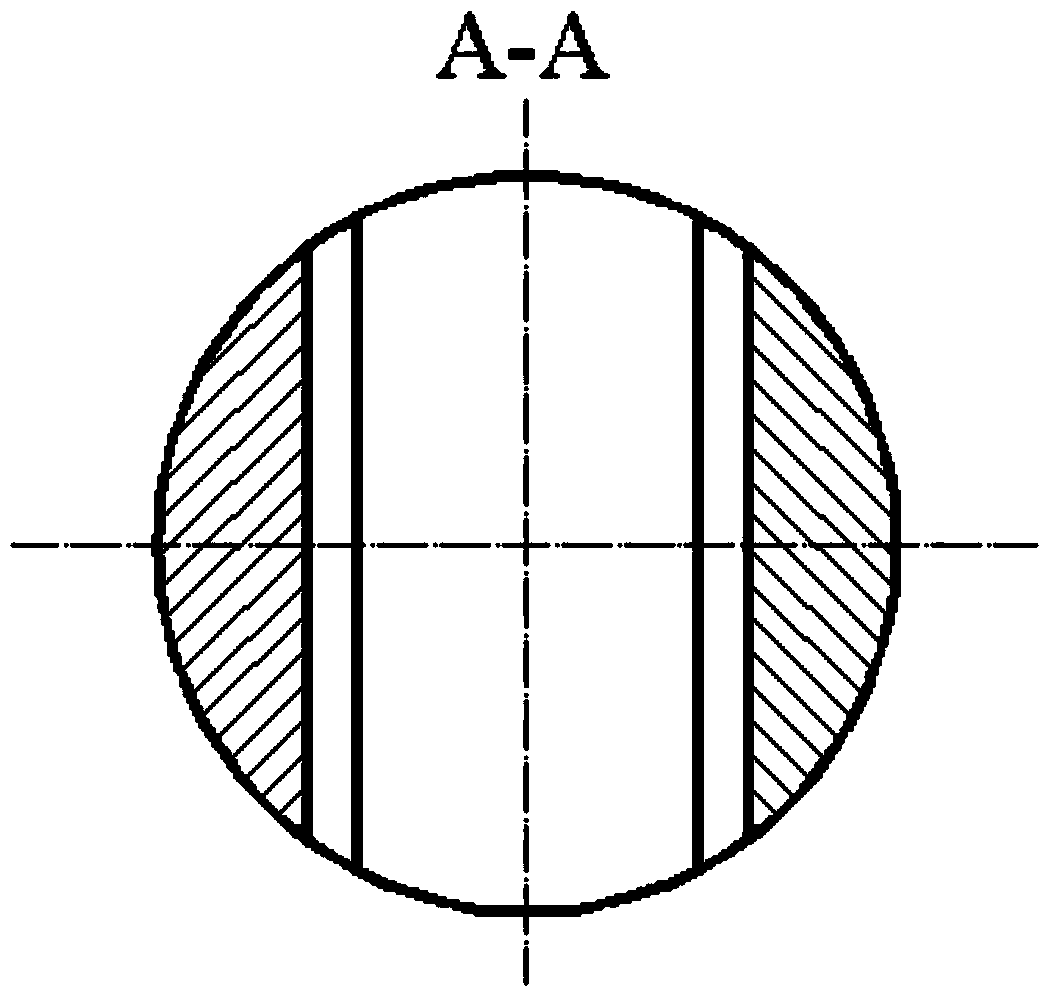

[0022] Such as figure 1 As shown, a tensile test fixture of a high-pressure hydrogen environment material testing machine is divided into two parts: an upper fixture and a lower fixture; , the center of the upper spherical cavity seat 7 has a hole and a spherical cavity inside; the cylindrical part of the lower end of the upper spherical hinge support 8 is connected to the sample 2 through a threaded hole, and the spherical crown body is arranged in the middle, and its spherical outer surface is in contact with the upper The spherical surface of the inner cavity of the ball cavity seat 7 cooperates to form a ball hinge rotary pair; one end of the upper load transmission frame 9 has a central hole for the free movement of the cylindrical part of the upper ball hinge support 8, and the other end has a threaded hole to connect with the fixed rod 1 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com