Testing device and testing method for thermal performance of phase-change temperature regulation building material

A technology of testing equipment and testing methods, which is applied in the investigation stage/state change, etc., can solve the problems of inability to test large-scale phase-change temperature-adjusting building materials, etc., and achieve the effect of simple testing methods and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] 2) Preparation of samples

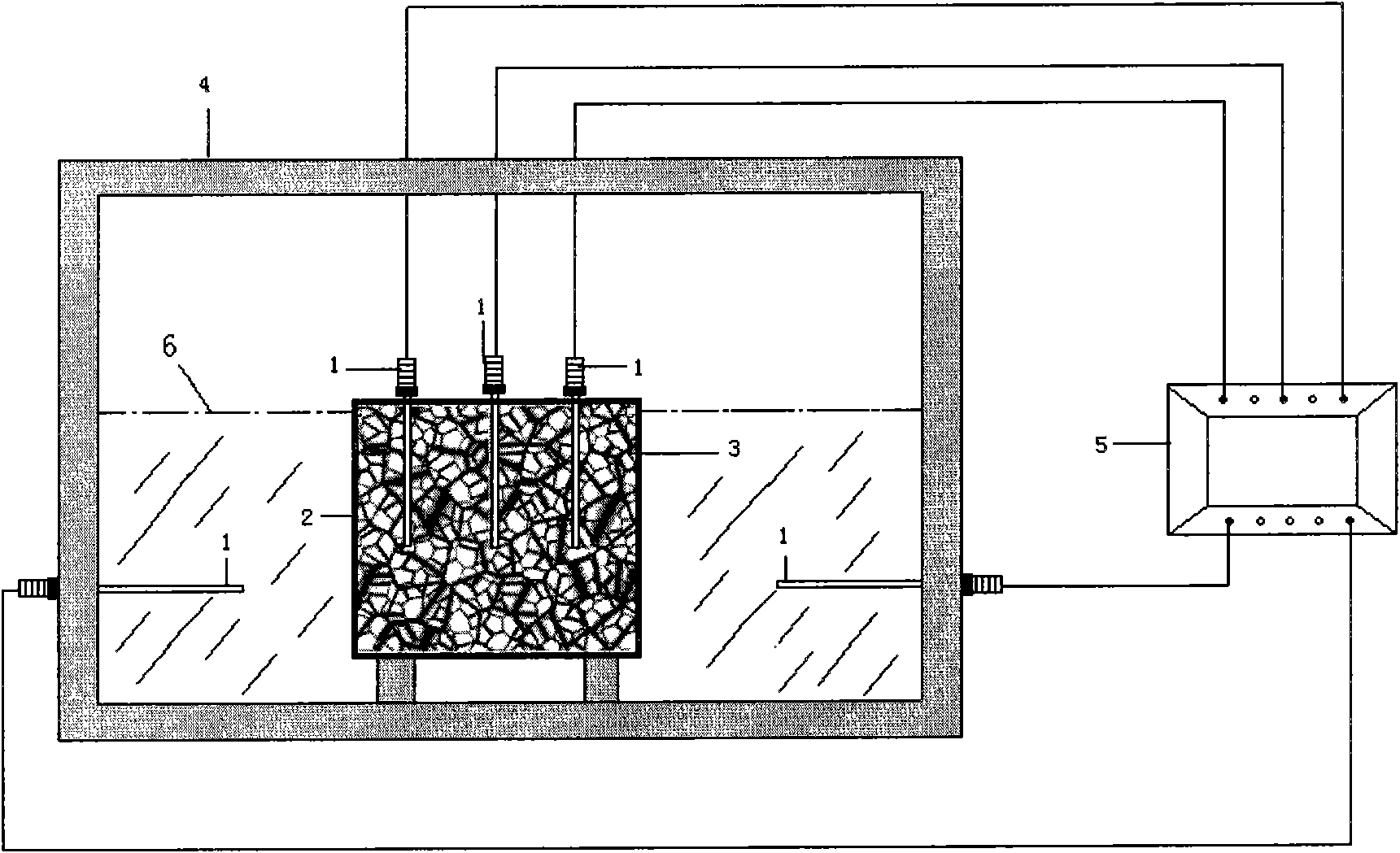

[0051] The sample to be tested in the test of the present invention should be a finished product state, and the total volume of the sample is ≥0.03m 3 . If the sample is in liquid or granular state (particle size ≤ 3mm), it can be directly put into the sample container for testing; Put it into the sample container, and weigh the mass of the sample (denoted as m). After the sample is installed, install 3 thermocouples on the outside to the middle of the sample respectively (such as figure 1 shown). Then cover the container lid, at the laboratory temperature (T 0 ) for 24 hours.

[0052] 3) Preparation of hot water

[0053] Take 10L of pure water, heat the water to above 80°C with a heating device, then pour it into the incubator, and cover the incubator with the lid.

[0054] 4) Addition of samples

[0055] After adding hot water for 3 hours, open the lid of the incubator, quickly put the prepared sample container into the water in the...

example 1

[0073] Example 1: The sample used in this example is expanded perlite-paraffin organic-inorganic composite phase change particles, and the test operation is carried out according to the above test steps. The specific values in the operation are:

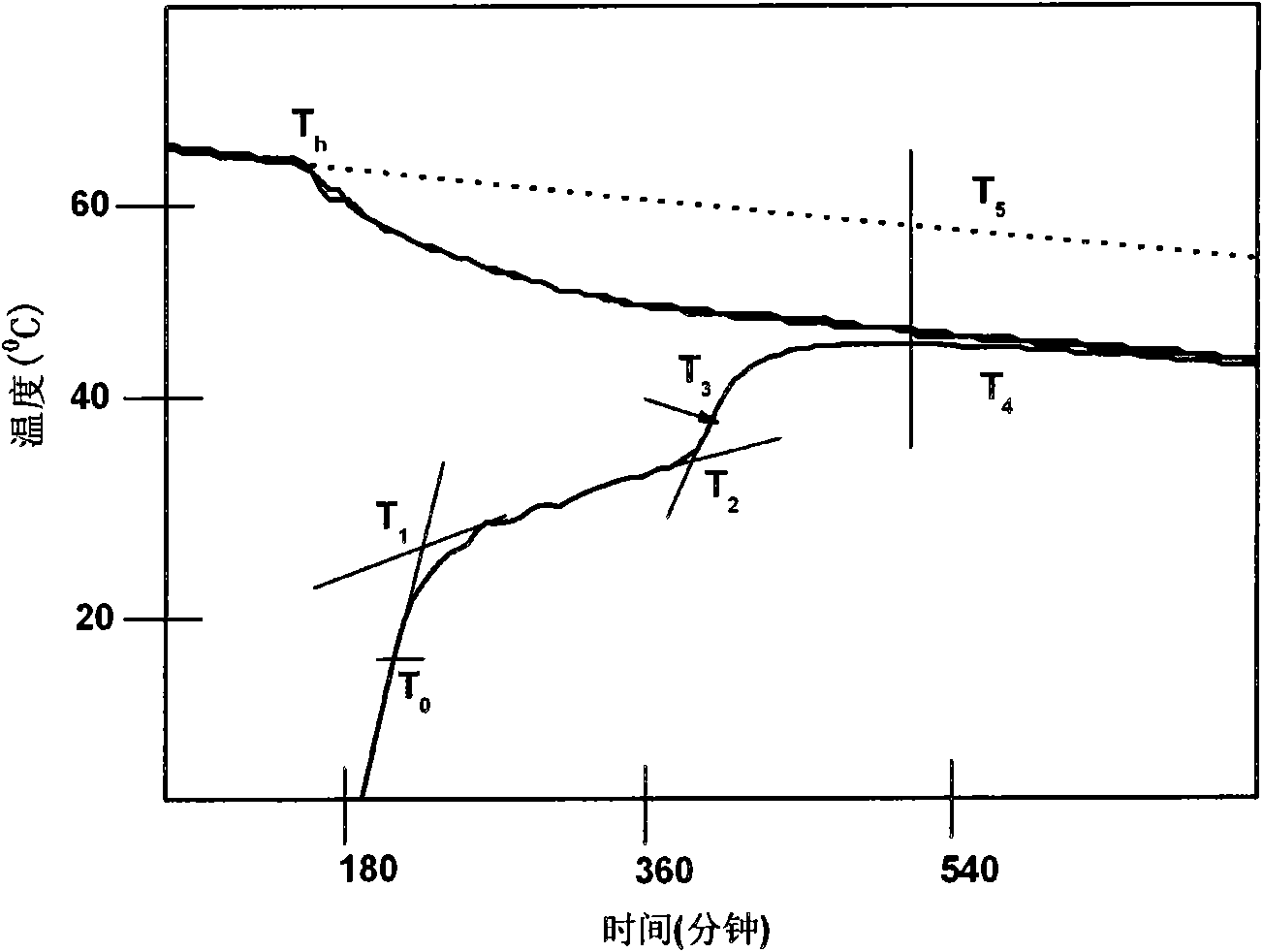

[0074] Ambient temperature T in step 1) 0 18°C; in step 2), the sample particle size is 0.5-2.0mm, the size of the sample container is 0.3m×0.3m×0.3m, and the total sample volume is 0.027m 3 , the mass m is 7.56kg; step 4) use the incubator with a volume of 0.53m×0.32m×0.32m, and record the hot water temperature T h is 65°C, the equilibrium final temperature T recorded in step 5) 4 43.8°C, T 5 is 60.1°C, the sample heating curve drawn in step 6) is as follows figure 2 shown. Depend on figure 2 From the heating curve of the medium sample, it can be seen that the sample has a first temperature inflection point about 35 minutes after the sample is put into the sample, and a second temperature inflection point at 130 minutes, ...

example 2

[0077] Example 2: The sample used in this example is a phase-change tempering mortar mixed with 50% expanded perlite-paraffin organic-inorganic composite phase-change particles. Perform the test operation according to the above test steps, the specific values in the operation are:

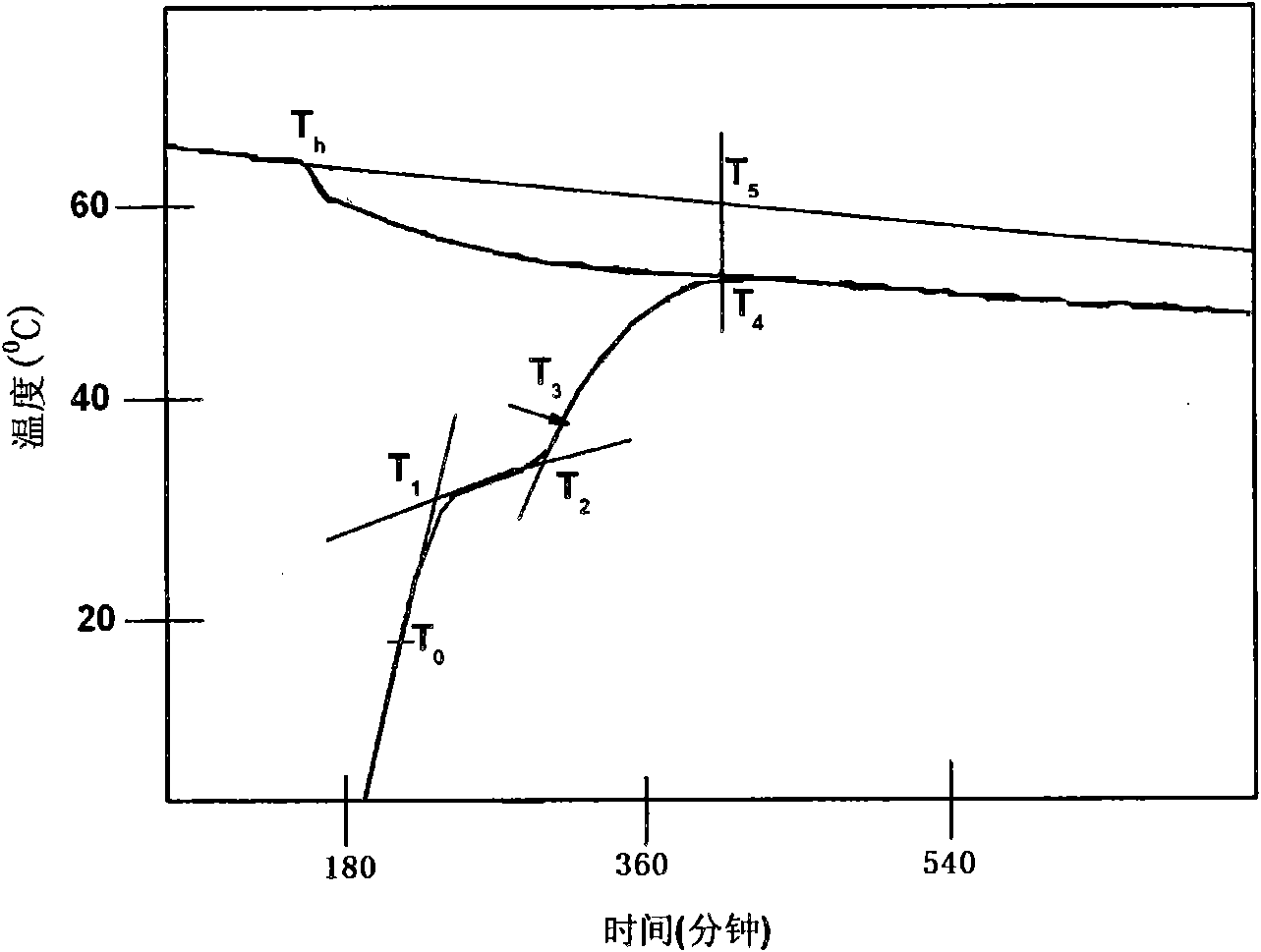

[0078] Ambient temperature T in step 1) 0 18°C; in step 2), the sample particle size is 0.5-2mm, the sample container size is 0.3m×0.3m×0.3m, and the total sample volume is 0.027m 3 , the mass m is 10.8kg; step 4) use the incubator with a volume of 0.53m×0.32m×0.32m, and record the hot water temperature T h is 65°C, the equilibrium final temperature T recorded in step 5) 4 45.6°C, T 5 is 60.2°C, the sample heating curve drawn in step 6) is as follows image 3 shown. Depend on image 3 From the heating curve of the medium sample, it can be seen that the sample has a first temperature inflection point when the temperature is measured for about 43 minutes, and a second temperature inflection p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com