Grinding experiment method under single grain multi-level speed conditions

A single abrasive grain and experimental method technology, applied in the direction of testing wear resistance, etc., can solve the problems of inability to carry out high-speed and ultra-high-speed grinding experiments, low experimental speed, large abrasive grain size, etc., to improve efficiency and ensure accuracy Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

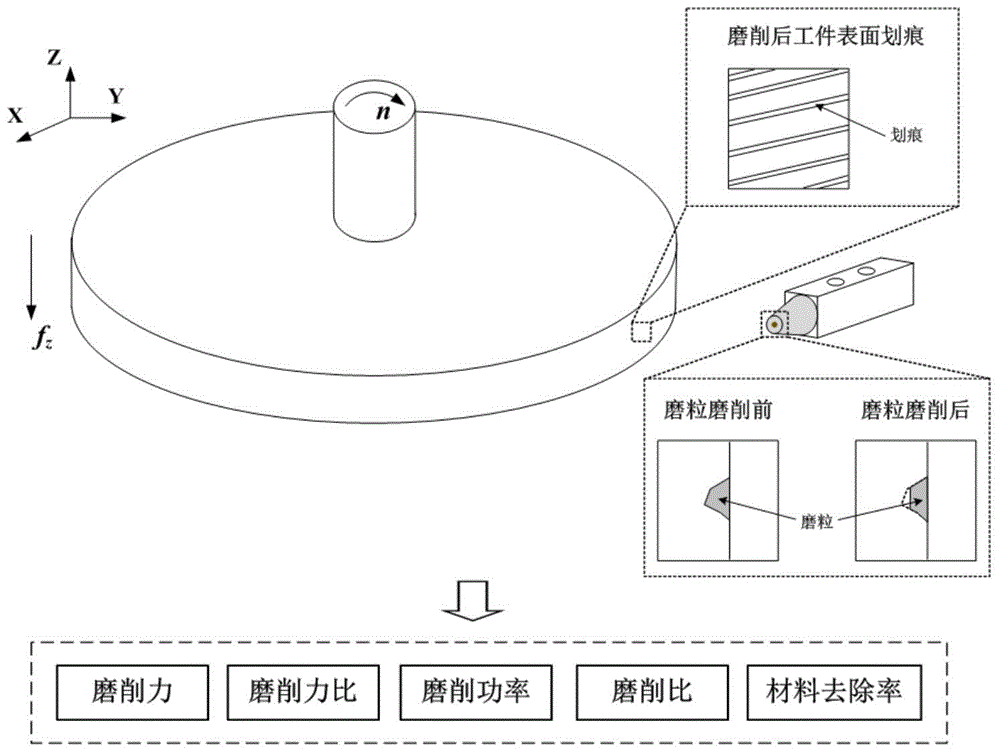

[0022] like figure 1 Shown, the grinding experimental method under the condition of a kind of single grain multi-stage velocity of the present invention, comprises the following steps:

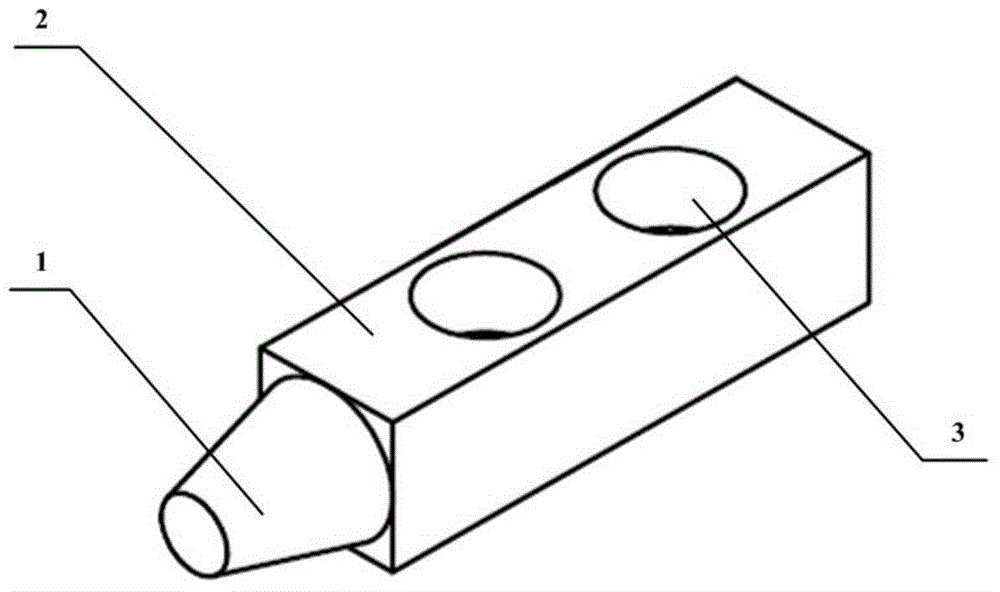

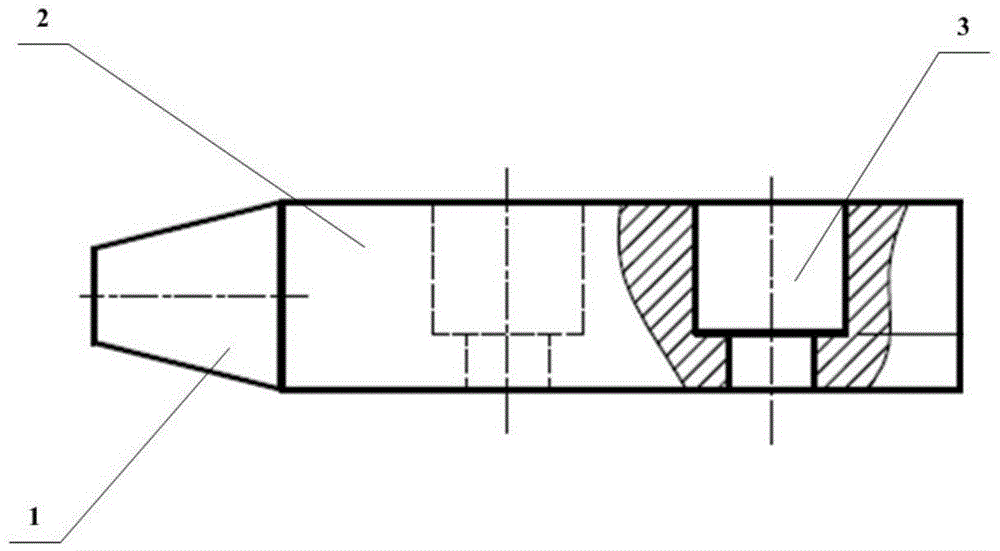

[0023] Step 1: Preparation and observation of a single abrasive tool: prepare a single abrasive tool according to the appearance shown in Figure 2, and inlay different types and different grain sizes of abrasives on the front end of the single abrasive tool head 1 according to the experimental requirements. on flat surface. If the abrasive is inlaid by electroplating or electroless plating, the proportion of the embedded part of the abrasive can be selected to be about 60%, which can ensure that the abrasive grains have sufficient holding force and effective edge height at the same time; The processing should ensure high flatness and parallelism req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com