Testing device for current auxiliary type micro-stretching mechanical property of metal thin plate

A metal sheet and testing device technology, which is used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc., to achieve the effects of remarkable cooling effect, accurate measurement results, and simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

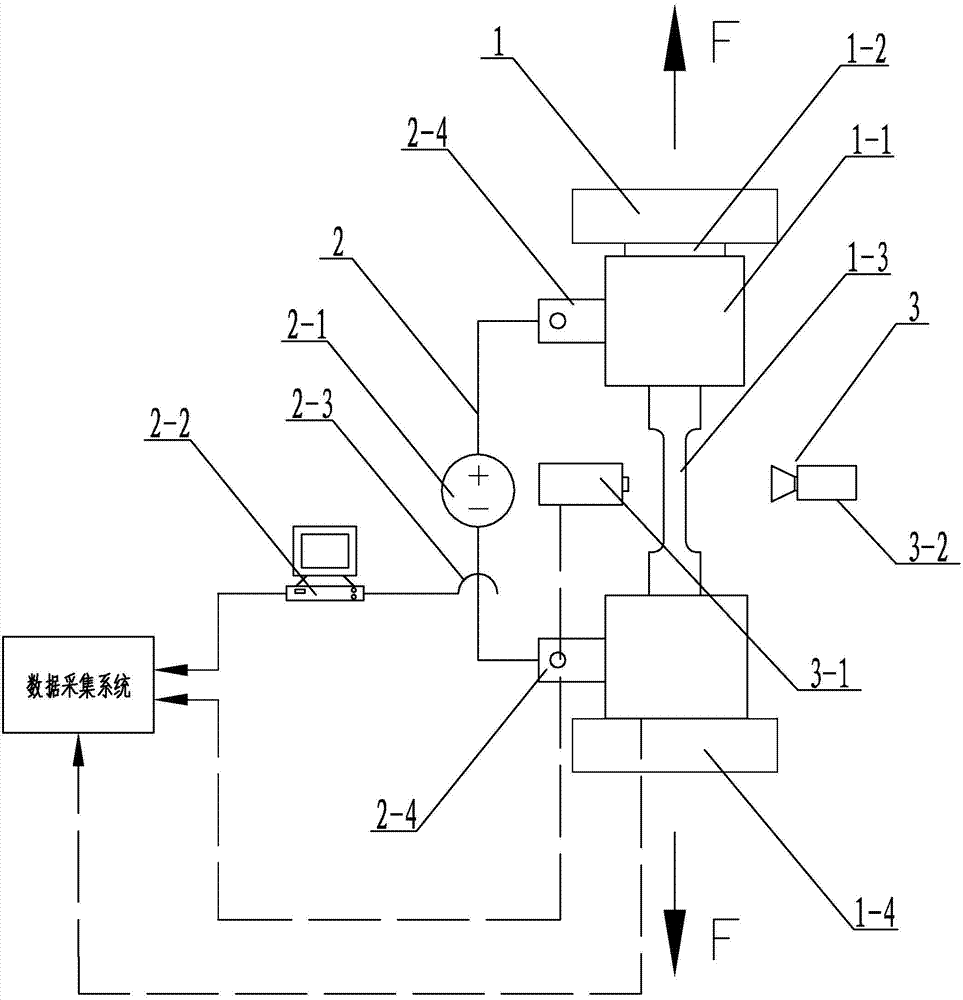

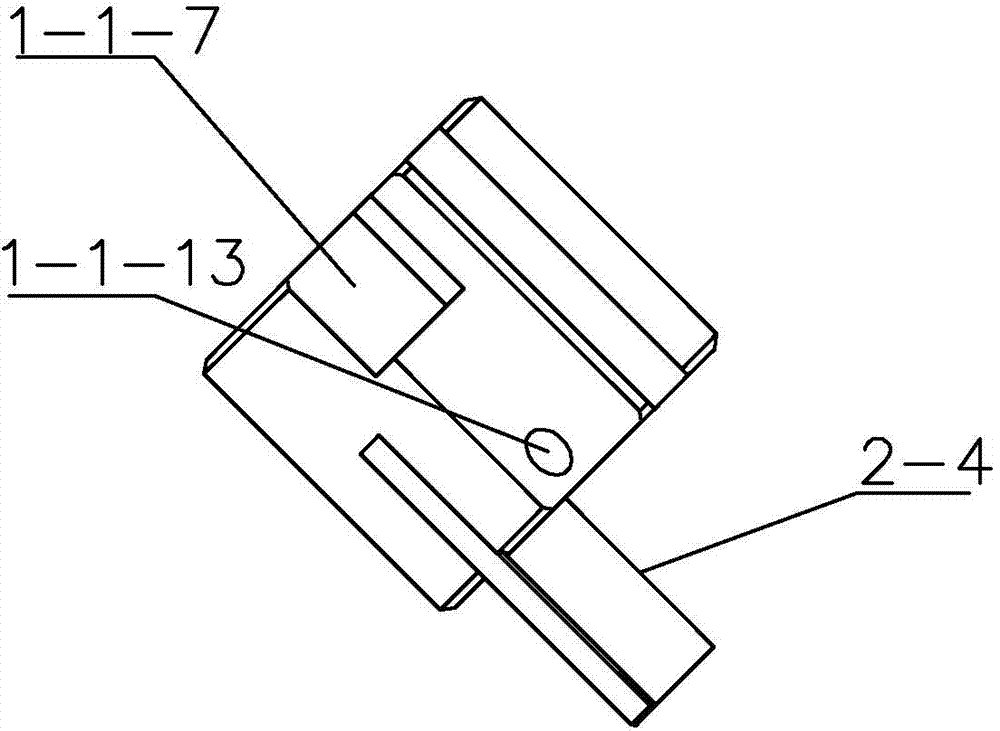

[0015] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment mode, a kind of metal thin plate electric current assisted micro-tensile mechanical performance testing device of this embodiment mode comprises uniaxial tensile test device 1, electric current generation and electrical parameter acquisition device 2 and temperature control and temperature acquisition device 3, described The unidirectional tensile test device 1 includes two sets of clip bodies 1-1, force sensors 1-2 and universal material testing machine 1-4, the force sensor 1-2 is installed on the lower part of the universal material testing machine 1-4 moving beam, two groups The clamp body 1-1 is symmetrically installed on the universal material testing machine 1-4 through a pin connection, the micro-tensile sample 1-3 is installed between two sets of clamp bodies 1-1, and the current generation and electrical parameter acquisition device 2 includes a pulse Power s...

specific Embodiment approach 2

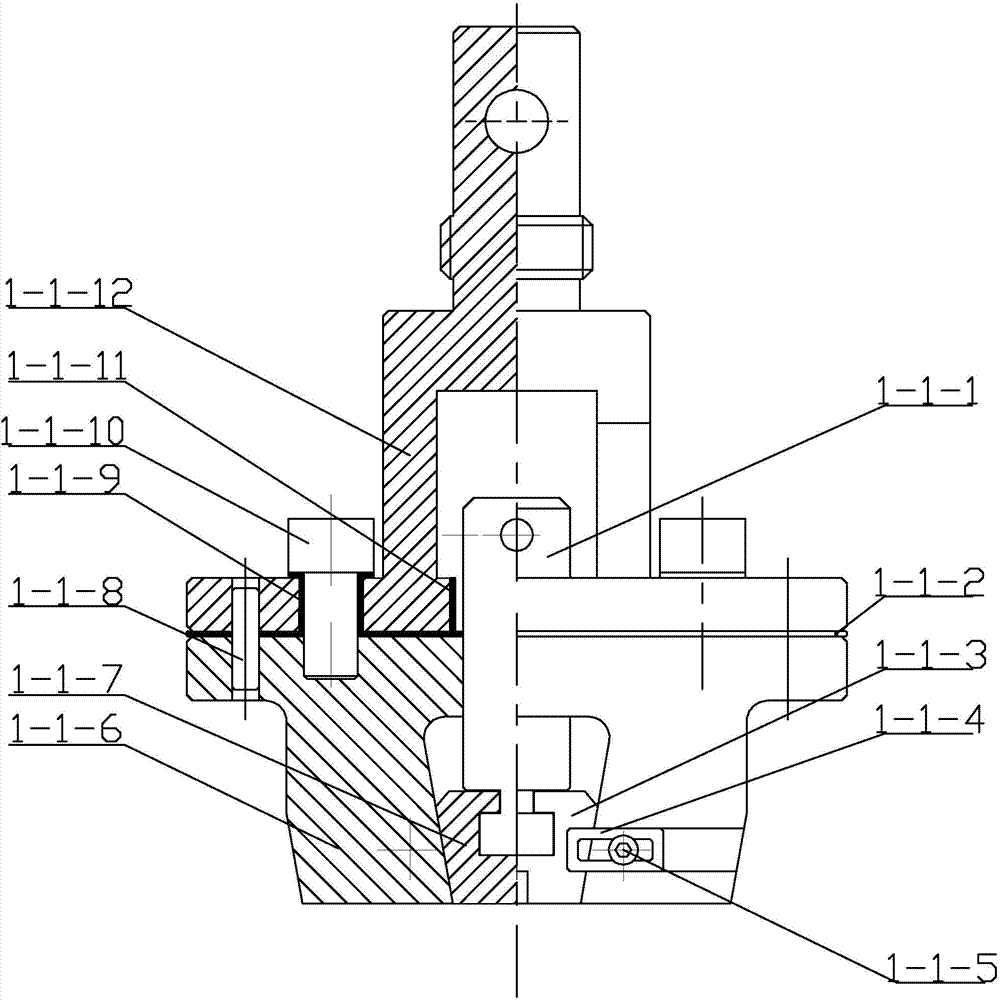

[0017] Specific implementation mode two: combination figure 2 To illustrate this embodiment, each group of clamp bodies 1-1 in the two sets of clamp bodies 1-1 of this embodiment includes a pressure plate 1-1-1, a mica insulating plate 1-1-2, and a right wedge-shaped clamp block 1-1 -3. Baffle plate 1-1-4, lower clamp body 1-1-6, left wedge clamp block 1-1-7, upper clamp body 1-1-12, two first insulating sleeves 1-1- 9. The second insulating sleeve 1-1-11 and two alumina ceramic insulating tapered pins 1-1-8.

[0018] The pressure plate 1-1-1 is screwed on the threaded hole of the lower clamp body 1-1-6, and the upper clamp body 1-1-12 is tightened with the lower clamp body 1-1-6 through two hexagon socket bolts 1-1-10. The mica insulation board 1-1-2 is arranged between the upper clamp body 1-1-12 and the lower clamp body 1-1-6, and the upper clamp body 1-1-12 and the lower clamp body 1-1- 6 Positioning by two alumina ceramic insulating tapered pins 1-1-8, each first insul...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the clamping planes of the left wedge-shaped clamping block 1-1-7 and the right wedge-shaped clamping block 1-1-3 of this embodiment are provided with serrations. Such setting increases the coefficient of static friction between the micro-tensile sample and the wedge clamp. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com