Characterization method for compression stress softening and transient-persistent deformation of elastic body

A technology of compressive stress and permanent deformation, which is applied in the characterization of compressive stress softening and transient permanent deformation of elastomers, and the quantitative characterization of elastic compressive stress softening and transient permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Characterization of Compressive Stress Softening and Transient Permanent Set of Cyclic Compression of NBR Vulcanized Rubber

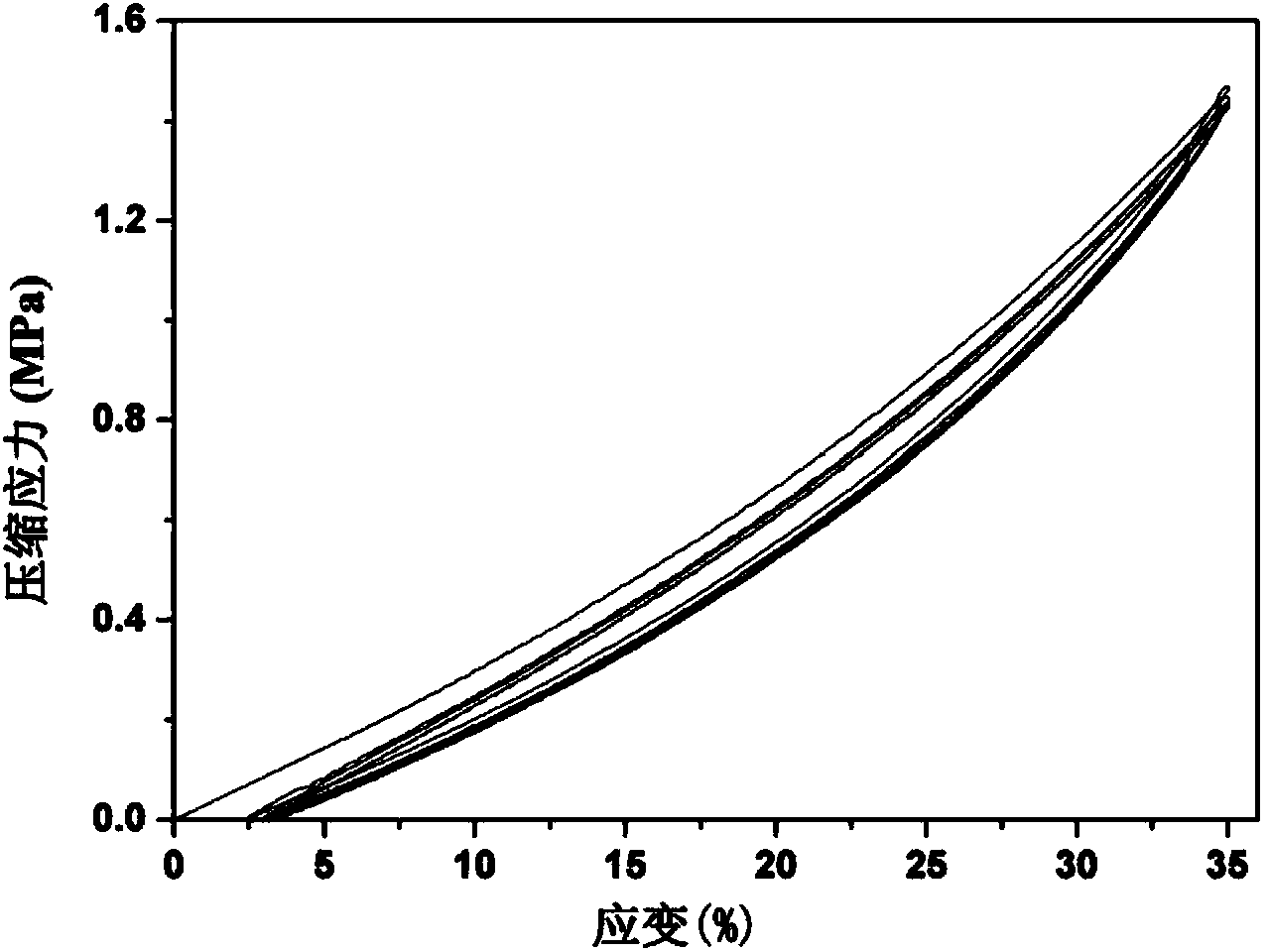

[0020] Prepare cylindrical NBR vulcanized rubber samples by molding method, and the samples should not have air bubbles, impurities and damage. Use GT-TCS-2000 electronic tensile machine to carry out uniaxial cyclic compression test on the sample, the compression strain is 35%, the speed of the compression sample and the relaxation sample during the cyclic compression process are both 5mm / min; the sample is pressed according to the program Continuously carry out 5 cycles of compression under the set compressive strain; the compressive stress-strain curve is shown in figure 1 .

[0021] figure 1 The peak stress in each cyclic compression pack is the compressive stress corresponding to each compression to 35% compressive strain. Five uniaxial cyclic compressions were performed on NBR vulcanized rubber, and the compressive stress is sh...

Embodiment 2

[0022] Example 2: Characterization of Compressive Stress Softening and Transient Permanent Set of Cyclic Compression of Carbon Black Filled NBR Vulcanizates

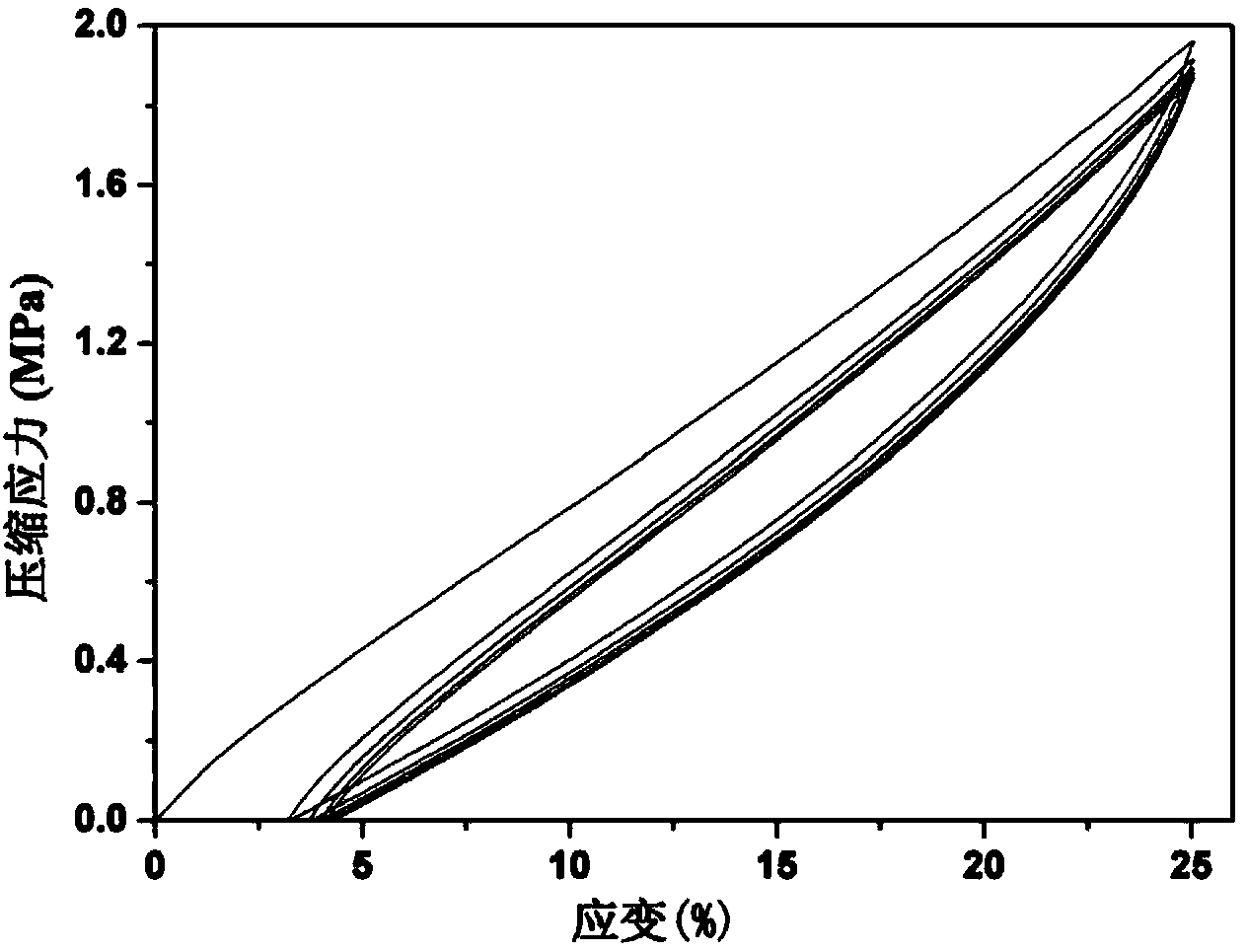

[0023] Prepare cylindrical carbon black-filled NBR vulcanized rubber samples by molding method, and the samples should not have air bubbles, impurities and damage. Use GT-TCS-2000 electronic tensile machine to carry out uniaxial cyclic compression test on the sample, the compression strain is 25%, the speed of the compressed sample and the relaxed sample during the cyclic compression process are both 5mm / min; the sample is pressed according to the program Continuously carry out 5 cycles of compression under the set compressive strain; the compressive stress-strain curve is shown in figure 2 .

[0024] according to figure 2 The quantitative data of compressive stress softening and instantaneous permanent deformation of carbon black filled NBR vulcanized rubber calculated from the data in Table 2 are shown in Table 2. ...

Embodiment 3

[0025] Example 3: Characterization of Compressive Stress Softening and Transient Permanent Set for Cyclic Compression of Dynamically Vulcanized ABS / NBR Thermoplastic Elastomers

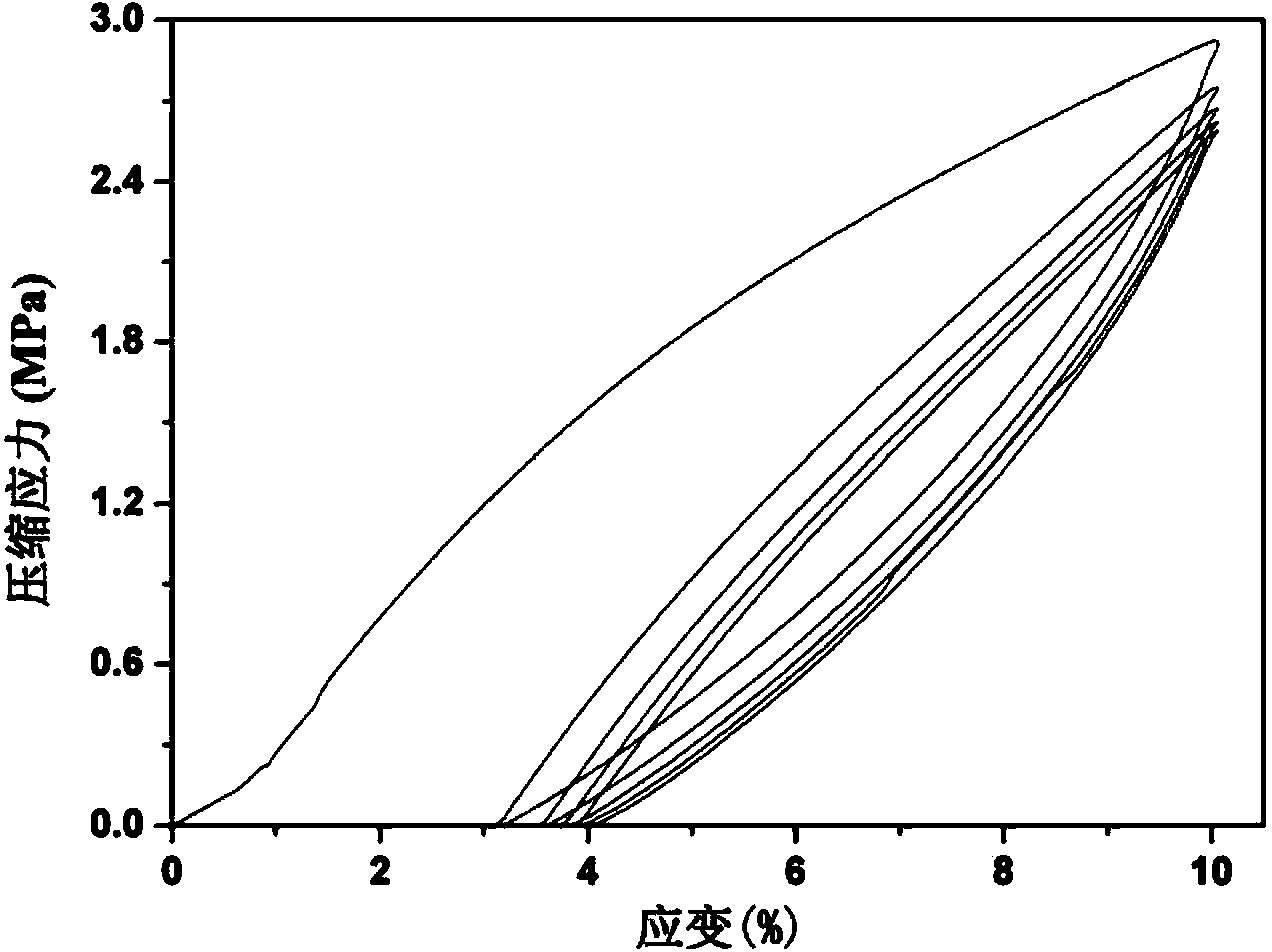

[0026] Prepare cylindrical dynamic vulcanized ABS / NBR thermoplastic elastomer samples by molding method, and the samples should not have air bubbles, impurities and damage. Use GT-TCS-2000 electronic tensile machine to carry out uniaxial cyclic compression test on the sample, the compression strain is 10%, the speed of the compressed sample and the relaxed sample during the cyclic compression process are both 5mm / min; the sample is pressed according to the program Continuously carry out 5 cycles of compression under the set compressive strain; the compressive stress-strain curve is shown in image 3 .

[0027] according to image 3 The quantitative data of compressive stress softening and instantaneous permanent deformation of dynamic vulcanized ABS / NBR thermoplastic elastomer samples calculated fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com