High-precision laminating machine

A laminating machine, high-precision technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of pressing thickness deviation, height limitation, difficult to quickly process parts with different thicknesses, etc., to achieve The effect of large rotational freedom, easy positioning and quick adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

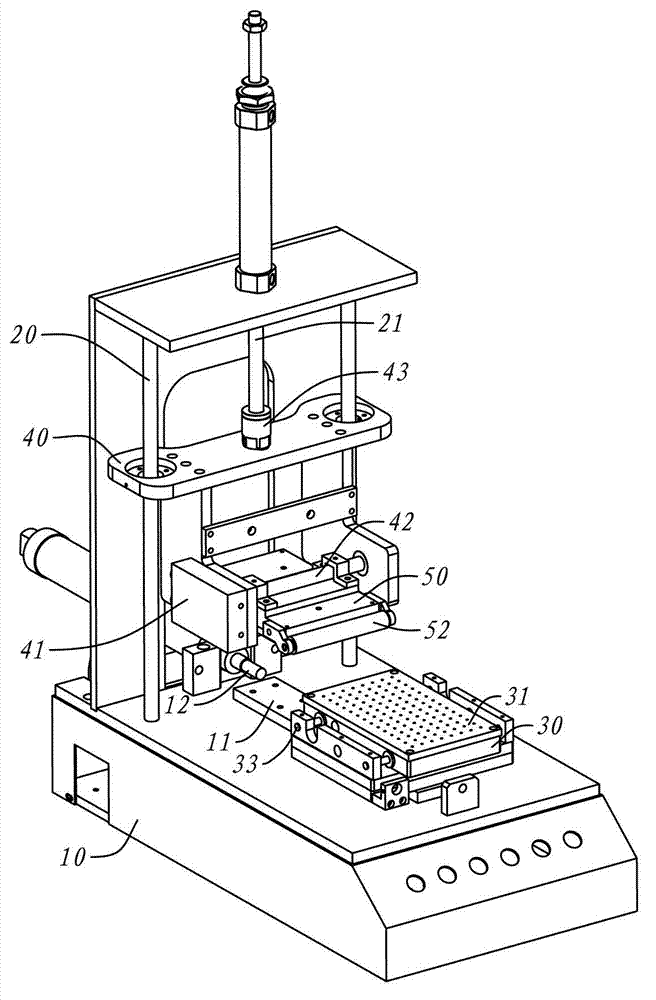

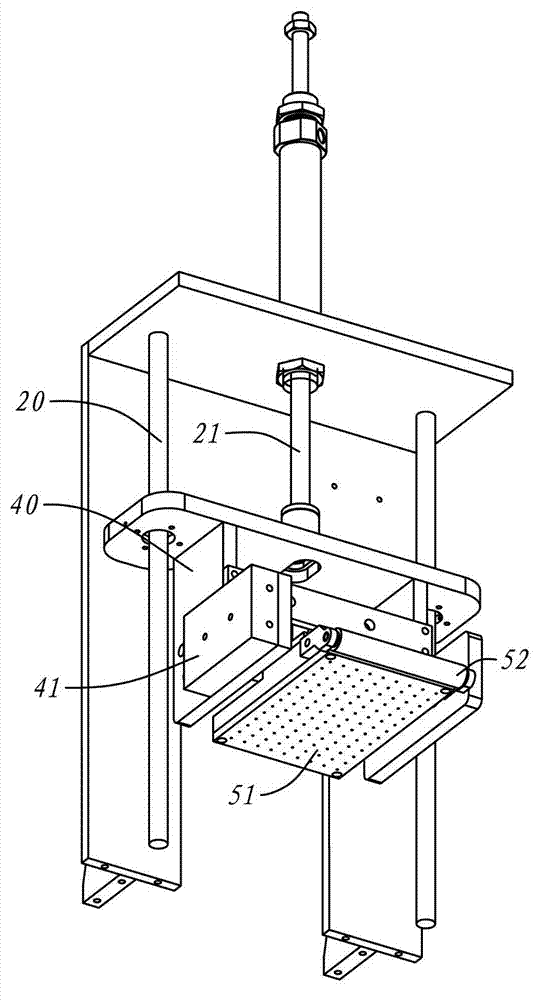

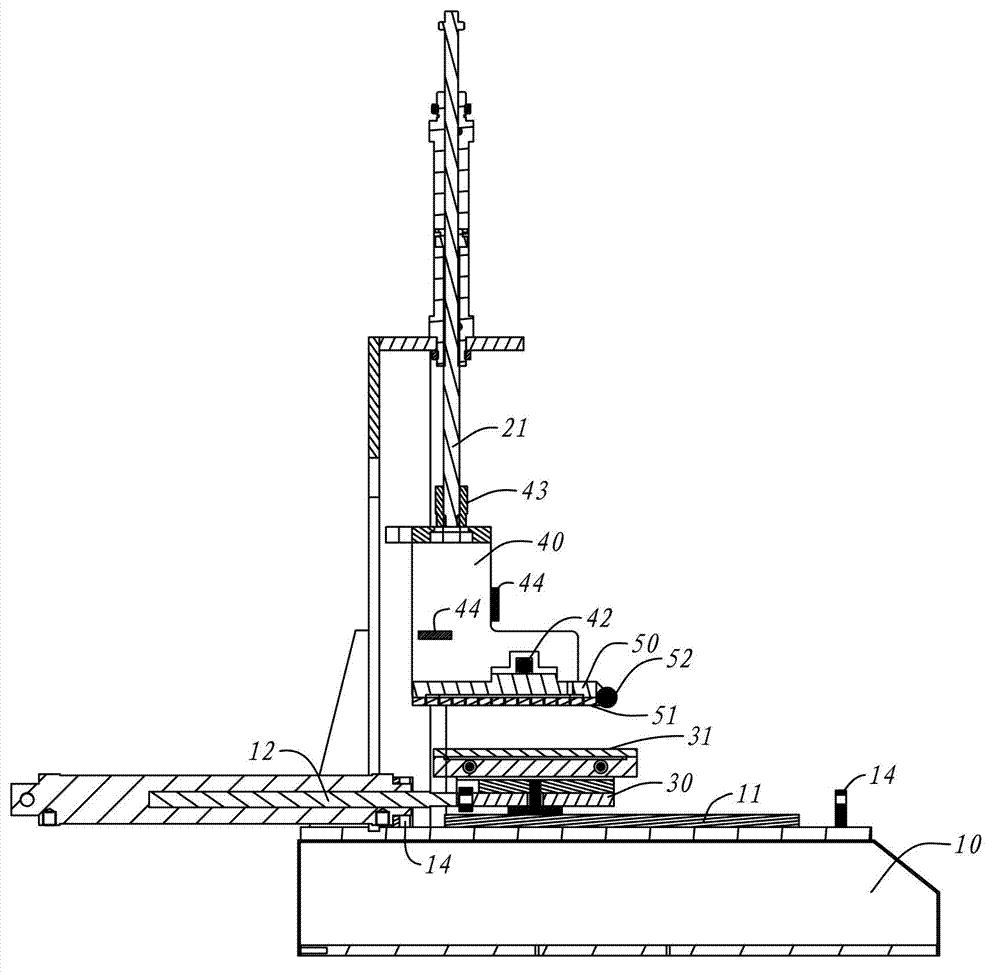

[0029] Such as Figure 1 to Figure 4 Shown is a schematic diagram of an embodiment of the present invention.

[0030] In this embodiment, a high-precision laminating machine is a device placed on a horizontal workbench. It includes a base 10 and a vertical rail 20 vertically fixed above the base 10. Wherein, the upper surface of the base 10 is provided with a horizontal rail 11, the horizontal rail 11 is arranged in a horizontal and linear shape, the horizontal rail 11 is movably matched with a platform 30, that is, the lower platform 30 can slide one-dimensionally along its direction on the horizontal rail ; The lower platform 30 is a carrying component, the top of which has a lower bonding surface 31, this lower bonding surface 31 is used for vacuum adsorption of the parts to be bonded.

[0031] The vertical rail 20 becomes the restraining mechanism for the upper part of the base 10. A sliding frame 40 is slidably fitted to the vertical rail 20, that is, the sliding frame 40 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com