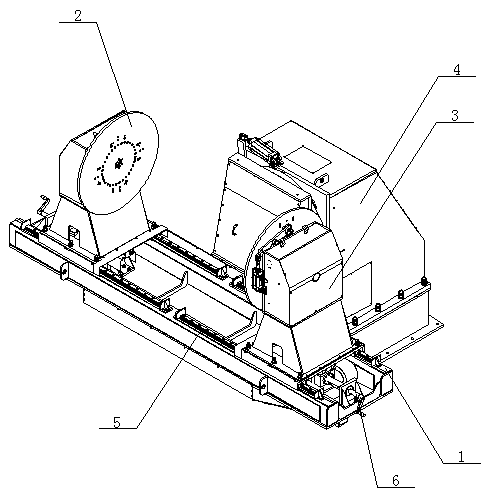

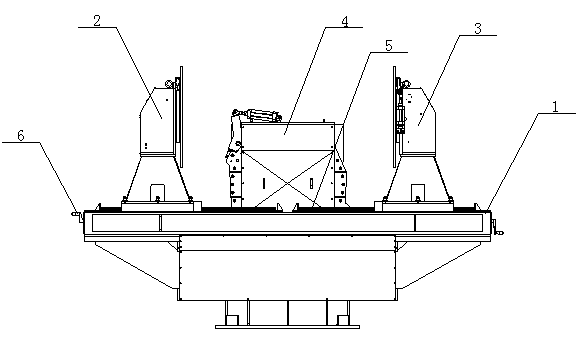

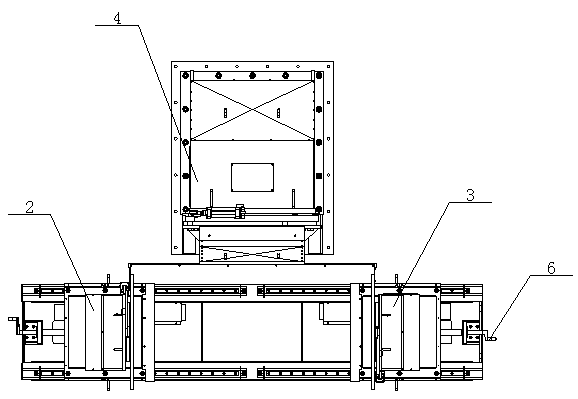

Double-shaft positioner

A positioner and positioner technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to meet, and achieve the effect of rich positions and postures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The invention is successfully applied to the surfacing welding of the rotor of the internal mixer in the plastic machinery industry. The rotor workpiece of the internal mixer is a typical irregular cylindrical surface. There is a section of cylinder at both ends of the workpiece, and the middle section is an irregular cylindrical surface. The cylindrical surface needs surfacing welding, and there are more than ten kinds of workpiece length specifications. During the surfacing welding process, the workpiece needs to be rotated in two directions to adjust to a suitable welding posture. The specific implementation steps are as follows: a. Make a good system configuration according to the welding system requirements ; b. Adjust the workpiece supporting device in the welding system in place; c. Adjust the limit block of the single-axis displacement head frame 2 to a suitable position, and use the screw drive mechanism 6 to adjust the single-axis displacement head frame 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com