Catalytic system and synthesis method of multi-block copolymer

A technology of catalytic system and synthesis method, which is applied in the field of chemical synthesis and can solve problems such as the rareness of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

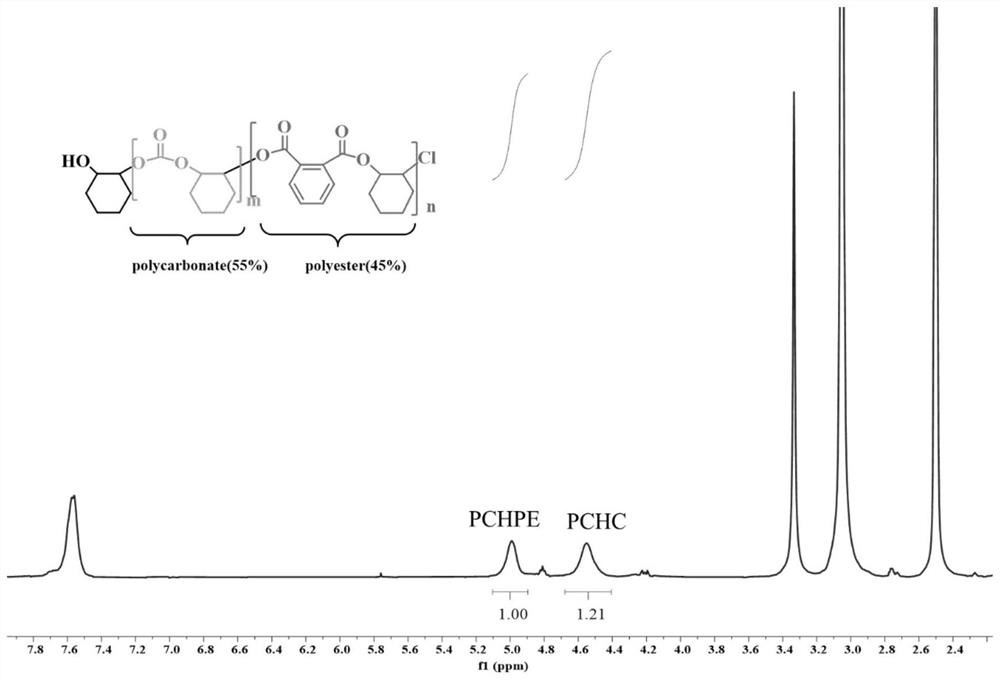

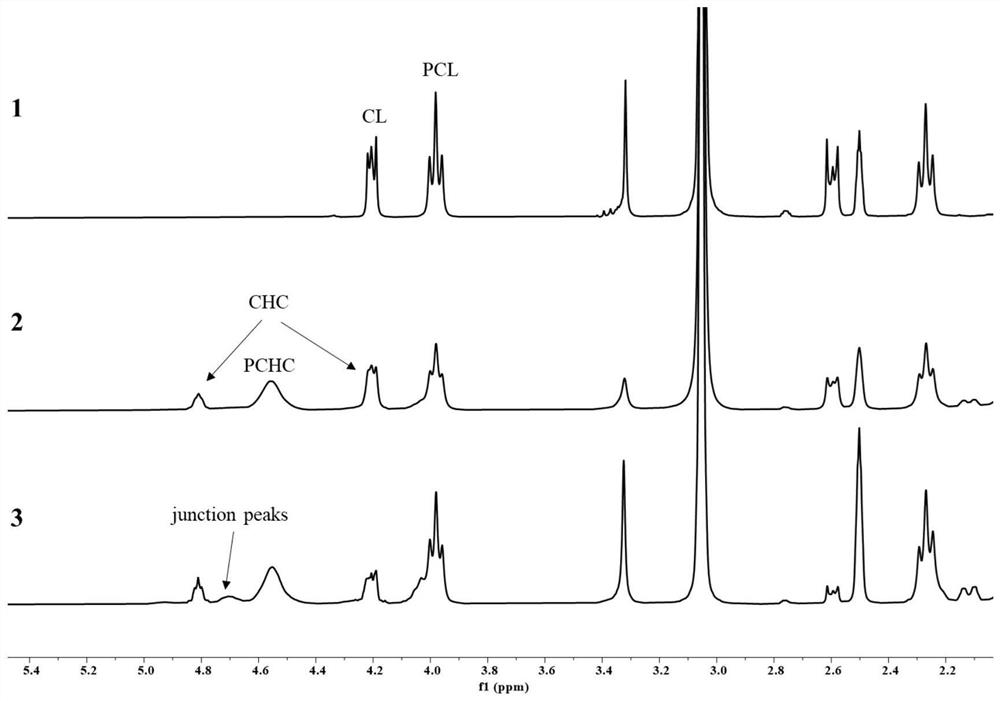

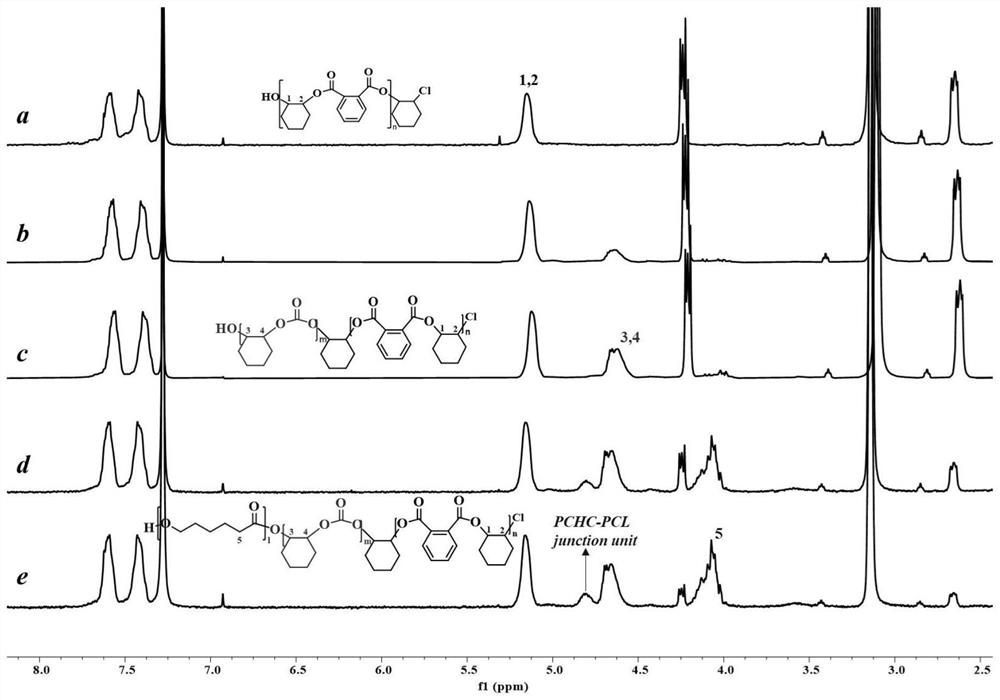

[0049] Under anhydrous and oxygen-free conditions, mix 0.02mmol of the compound of formula (I) and 0.02mmol of PPNCl with 20mmol of epoxycyclohexane (CHO) in a high-pressure reactor, and place it in an oil bath at 80°C for 48 hours with stirring , take about 0.3mL mixed solution as 300M 1 H NMR NMR samples were characterized, and the results showed that the conversion rate of CHO was 16%, and the reaction products were all cyclohexene carbonate (CHC) (>98% cis, <0.5% trans).

Embodiment 2

[0051] Under anhydrous and oxygen-free conditions, 0.02mmol formula (I) structure compound and 0.02mmol PPNNO 3 Mix it with 20mmol CHO in a high-pressure reactor, place it in an oil bath at 80°C and stir for 48 hours, take about 0.3mL of the mixed solution as 300M 1 The H NMR nuclear magnetic sample was characterized, and the results showed that the conversion rate of CHO was 7.6%, and the reaction product contained 22.2% polycyclohexene carbonate (PCHC) and 77.8% CHC (63.7% cis, 14.1% trans).

Embodiment 3

[0053] Under anhydrous and oxygen-free conditions, mix 0.02mmol of the compound of formula (I), 0.02mmol of PPNOAc and 20mmol of CHO in a high-pressure reactor, place it in an oil bath at 80°C and stir for 48 hours, and take about 0.3mL of the mixed solution as 300M 1 The H NMR nuclear magnetic sample was characterized, and the results showed that the conversion rate of CHO was 18.4%, and the reaction product contained 9.0% PCHC and 91.0% CHC (84.1% cis, 6.9% trans).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com