An automatic clamping device

An automatic clamping and pressing arm technology, applied in workpiece clamping devices, auxiliary devices, positioning devices, etc., can solve the problems of heavy weight, high price, complex structure, etc., to reduce parts and volume, reduce weight and volume , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

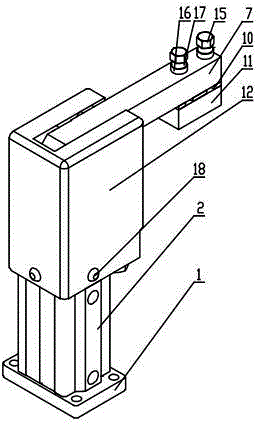

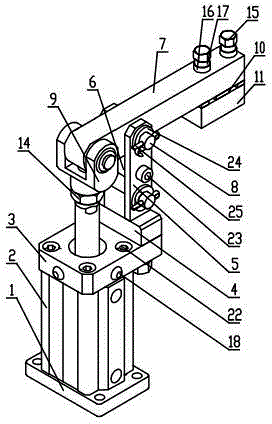

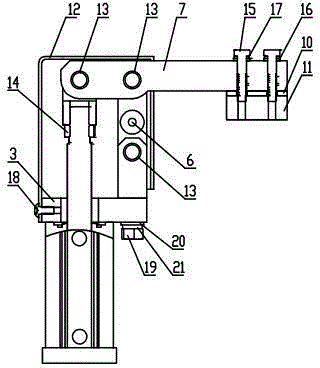

[0011] The present invention includes a base 1, a cylinder 2, a connecting seat 3, a connecting rod seat 4, a connecting rod 5, a connecting column 6, a pressing arm 7, a pin shaft 8, a Y-shaped joint 9, an adjusting gasket 10, a pressing block 11, a protective Cover 12, copper sleeve 13, lock nut 14, A screw 15, A flat washer 16, A spring washer 17, round head screw 18, B screw 19, B flat washer 20, B spring washer 21, C screw 22, D Screw 23, pin shaft flat pad 24, cotter pin 25, when installing, first install the cylinder 2 on the upper end of the base 1, fix the connecting seat 3 on the upper end of the cylinder 2 through the C screw 22, and then pass the B screw 19 through the B The spring washer 21 and the B flat washer 20 install the connecting rod seat 4 on the upper end of the connecting seat 3, set the two connecting rods 5 symmetrically on the upper end of the connecting rod seat 4, and fix the connecting column 6 on the two connecting rods through the D screw 23. Th...

Embodiment 2

[0013] When in use, first adjust the clamping position by adjusting the gasket 10, and the cylinder 2 moves upwards, thereby pushing the Y-shaped joint 9 upwards, driving the clamping arm 7 to perform a 90-degree rotation, and clamping and releasing the workpiece. The protective cover 12 protects the operating mechanism inside it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com