Mobile sponge shear type carrying device

A handling device and scissor-type technology, applied in metal processing and other directions, can solve the problems of inflexible movement, laborious, manual manual operation, etc., and achieve the effects of good economy, low equipment manufacturing cost, and flexible unloading action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

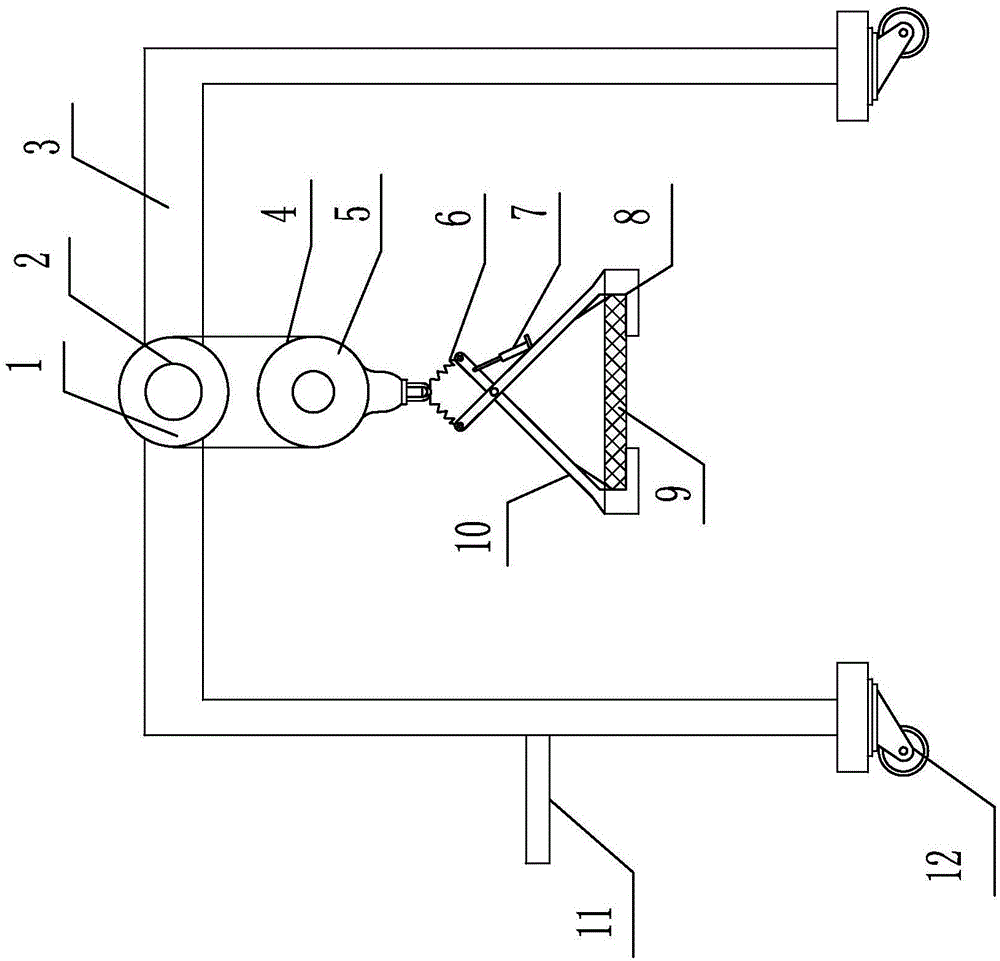

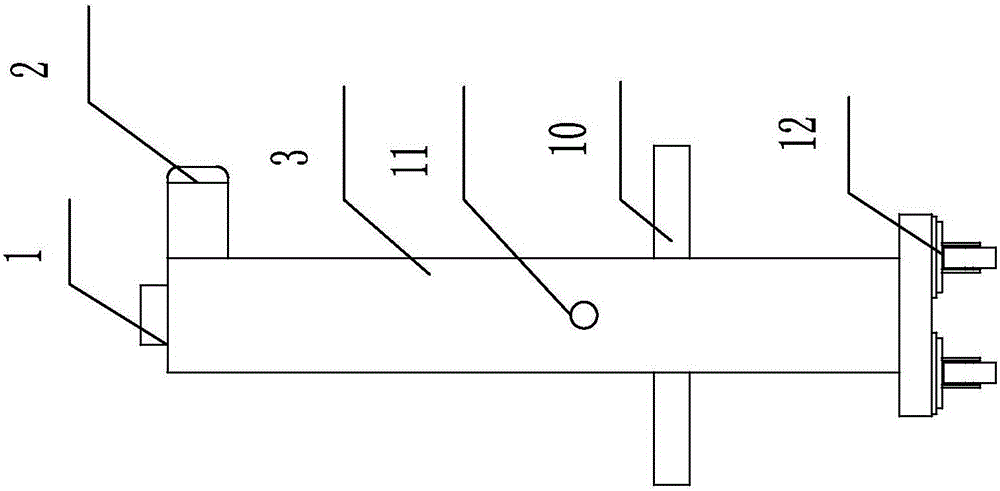

[0018] as attached figure 1 shown

[0019] The invention provides a movable sponge scissors type handling device, comprising a rope wheel 1, a motor 2, a frame 3, a traction rope 4, a hanger 5, a steel wire rope 6, an electro-hydraulic telescopic rod 7, a hanging claw A8, a sponge 9, a hanging Claw B10, push rod 11 and universal wheel 12; the upper end of the frame 3 is fixed with a motor 2 and a sheave 1 through bolts, the output shaft end of the motor 2 is connected with a sheave 1, and the traction rope 4 is coiled around the sheave 1, the lower end of the traction rope 4 is connected to the top of the spreader 5, and the two sides of the suspension ring at the lower end of the spreader 5 are respectively connected to the tops of the hanging claw A8 and the hanging claw B10 via a steel wire rope 6, and the upper ends of the hanging claw A8 and the hanging claw B10 are hinged together. The electro-hydraulic telescopic rod 7 is connected to the upper and lower ends of two sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com