Three-disc eyeglass sorting system

A sorting system and lens technology, applied in sorting and other directions, can solve the problems of high subjective influence of workers, low degree of automation, heavy workload, etc., and achieve strong expandability, strong continuity, and simple control of workstations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below with reference to the accompanying drawings and examples.

[0037]At present, lens manufacturers mainly rely on manual grading of lenses. This method has a large workload, a high rate of mispicking, a great influence of worker subjectivity, and a low degree of automation. At present, there is a system for sorting jujube products, but it is not suitable for products such as lenses, which are fragile and easily scratched on the surface.

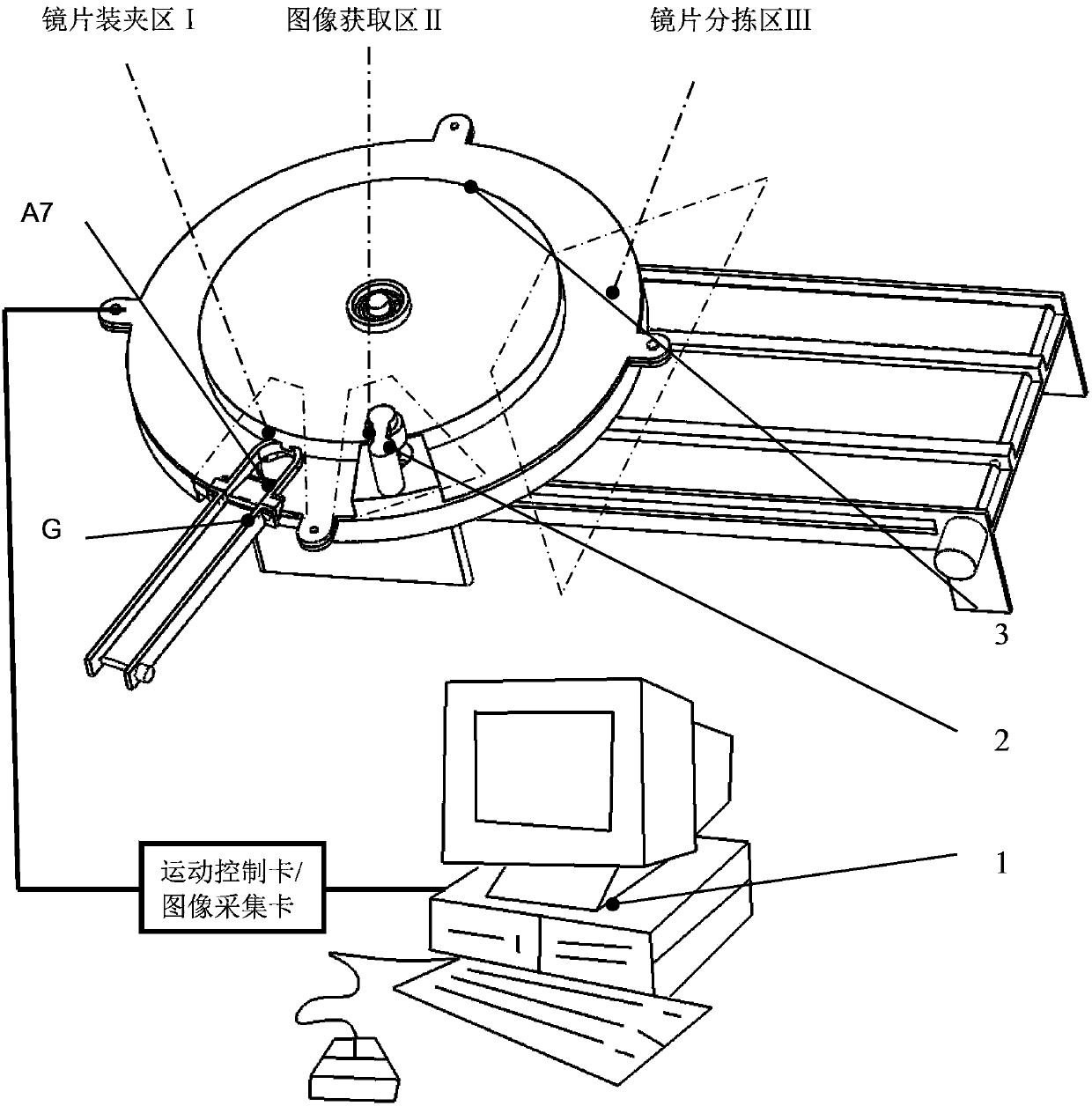

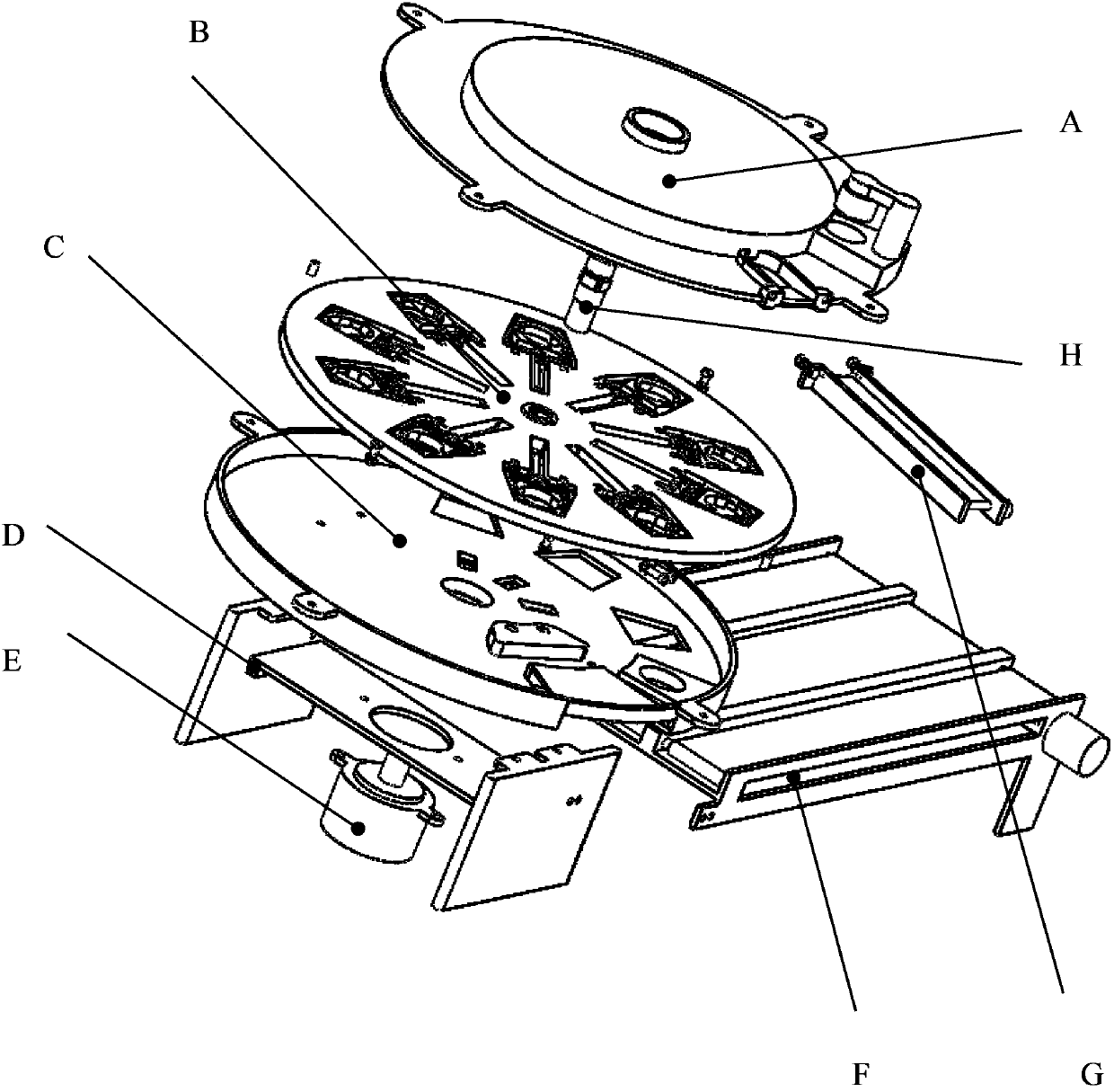

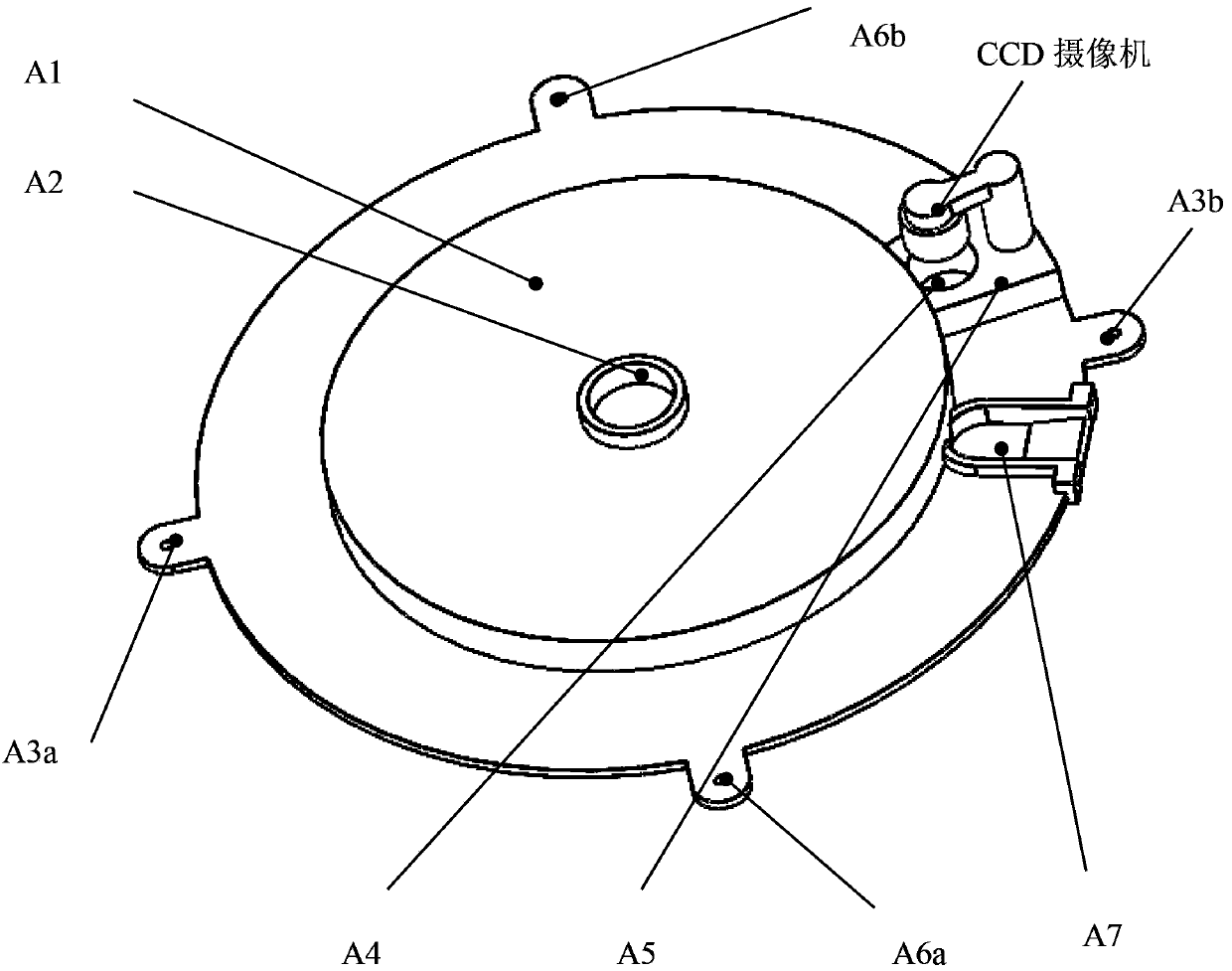

[0038] The principle of the present invention is as follows: the three-disk lens sorting system includes an image acquisition and image processing center, a three-disk sorting mechanism and its control center. The image acquisition is completed by a high-resolution camera, and the image processing center and the control center of the three-disk sorting mechanism of the present invention are industrial PCs. The motion control card is the link between the industrial PC and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com