Rivet inserter

A technology for inserters and anchors, applied in surgical instruments, applications, etc., can solve the problems of easy contact with sutures, pollution, and difficulty in finding thread ends. Fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

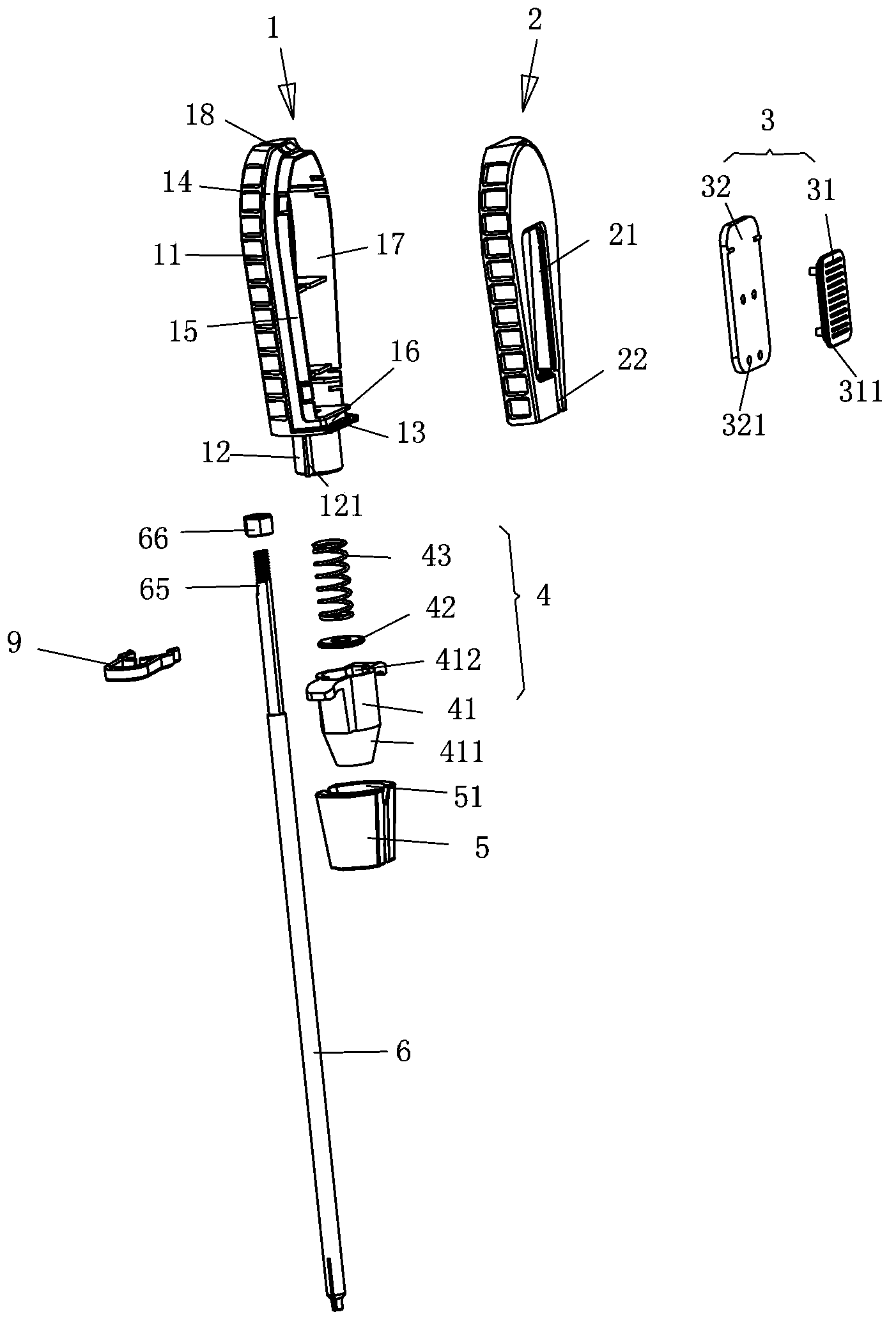

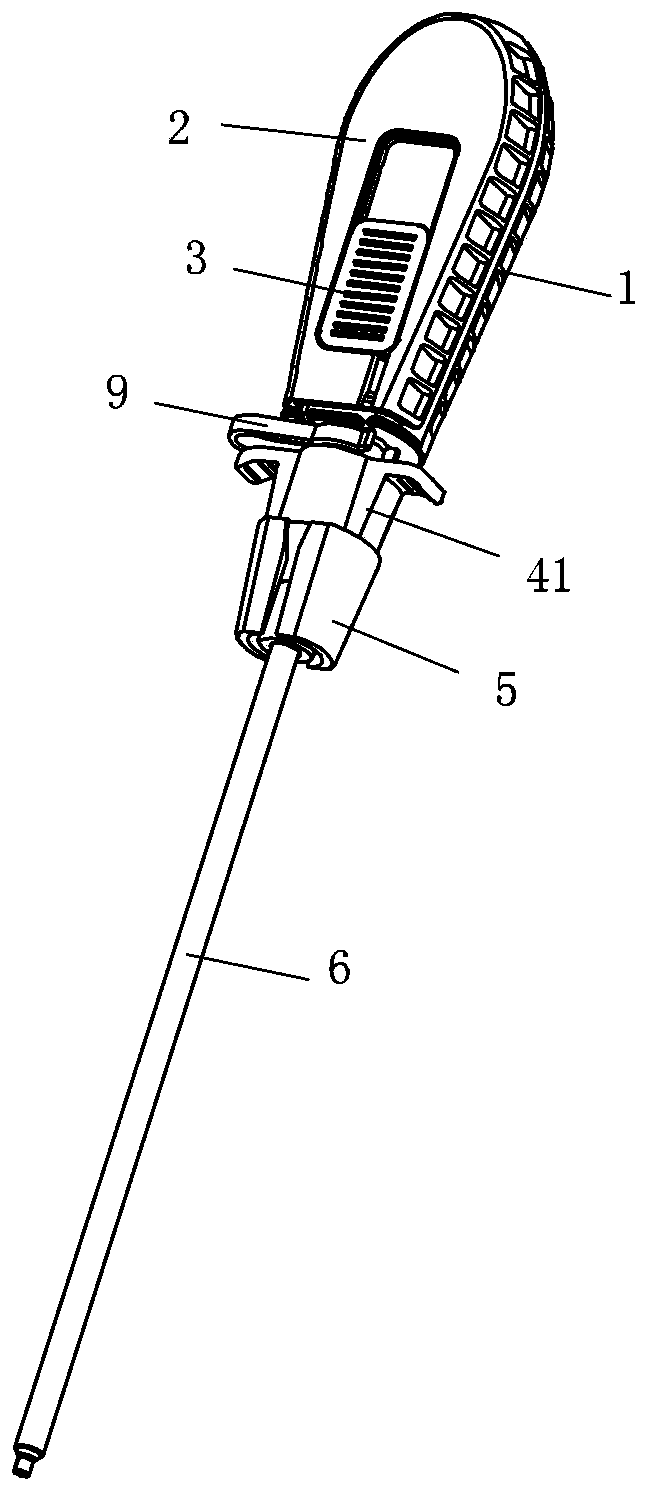

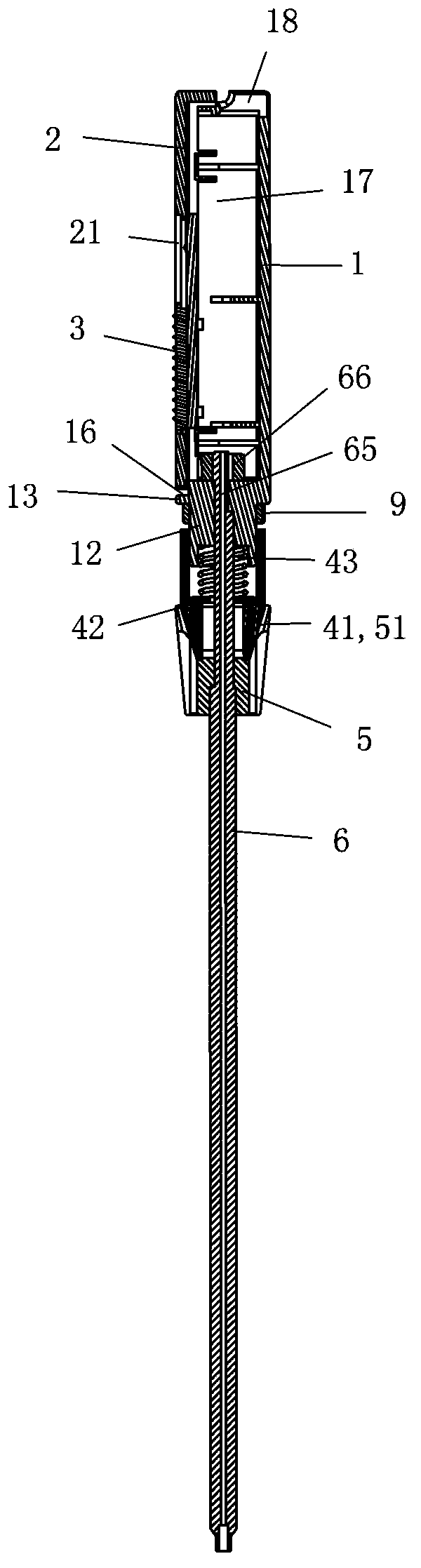

[0025] The structure of an embodiment of the anchor inserter of the present invention, please refer to figure 1 , figure 2 and image 3 . The anchor inserter has a handle, a wire crimping assembly 4, a fixing seat 5, a main rod 6 and a locking clip 9. The handle is composed of a handle main body 1, a handle cover 2 and a push-pull plate 3 ; The crimping assembly 4 is composed of a crimping seat 41 , a gasket 42 and a spring 43 . In the following, the upper part represents the rear in actual application, and the lower part represents the front in actual application.

[0026] The main part of the handle main body 1 is the grip part 11; the grip part 11 is a box body with an open right side, and a baffle 13 is arranged at the lower end, and the center of the lower surface of the baffle 13 extends downward to connect the crimping seat 41 The guide tube 12, the outer periphery of the guide tube 12 is provided with two opposite guide ribs 121, and the two guide ribs 121 are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com