Welding positioning dotter of pipe fittings

A technology for welding and fixing rings of pipe fittings, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of precise positioning and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

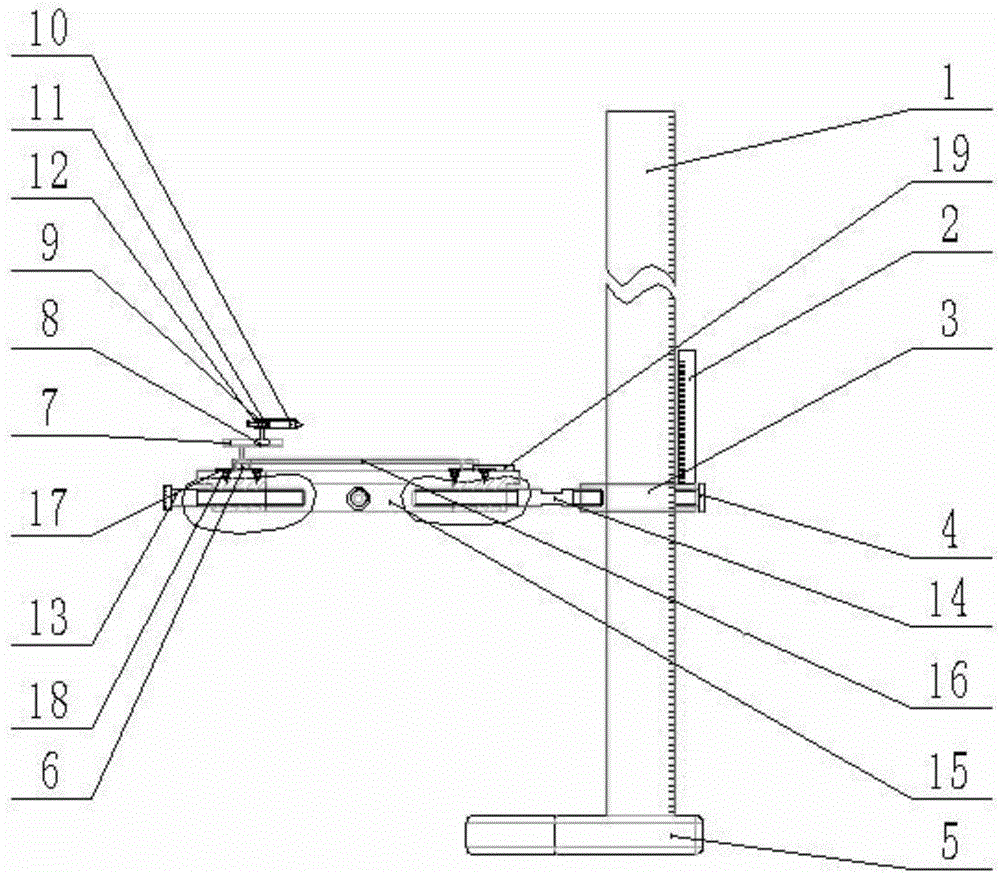

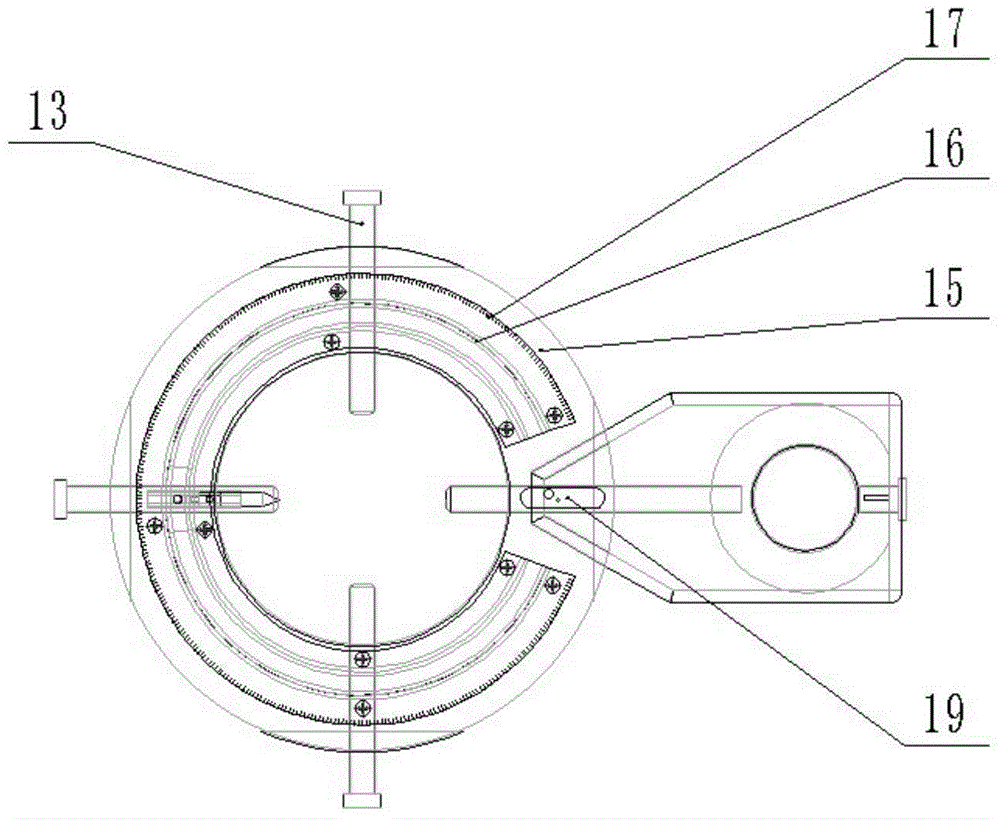

[0021] Such as figure 1 with 2 As shown, the pipe fitting welding positioning inking device of the present invention has a specific structure as follows:

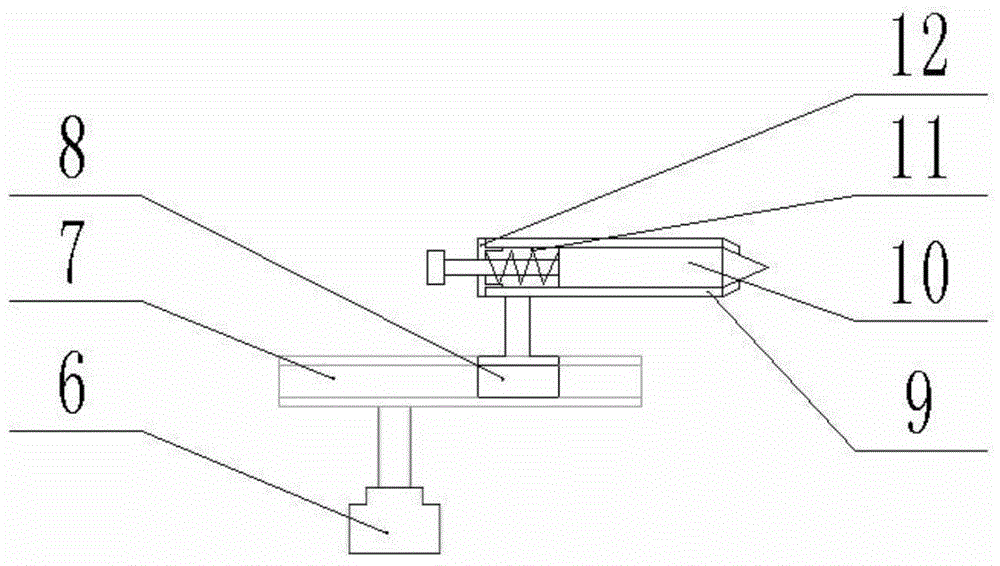

[0022] The height ruler 1 is welded on the base 5, the vernier ruler 2 is welded on the fixed ring 3, the fastening screw 4 is screwed into the fixed ring 3, and the fixed disc 15 is connected with the fixed ring 3 through a stud 14 And can move up and down with the fixed ring 3, the adjusting screw 13 is connected to the fixed disc 15 by thread, the slide block one 6 is embedded in the circular chute 16 and can slide in the circular chute 16, the circular chute 16 is spot-welded with the angle measuring disc 17, and connected to the fixed disc 15 with self-tapping nails 18, the second chute 8 is embedded in the linear chute 7, the dotting pen 10 is embedded in the dotting pen shell 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com