Cable processing equipment

A technology for processing equipment and cables, applied in the field of cable processing equipment, can solve the problem that the effect of the processing device is not ideal, and achieve the effect of saving resources, avoiding damage to the cable, and ensuring the clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

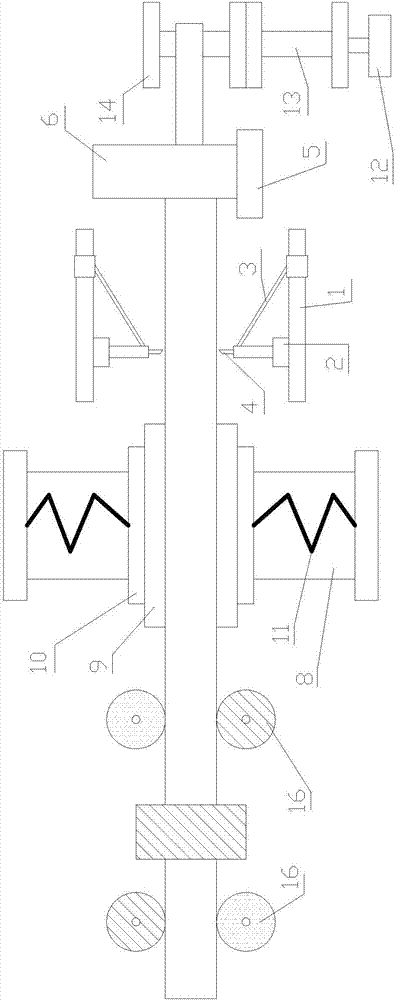

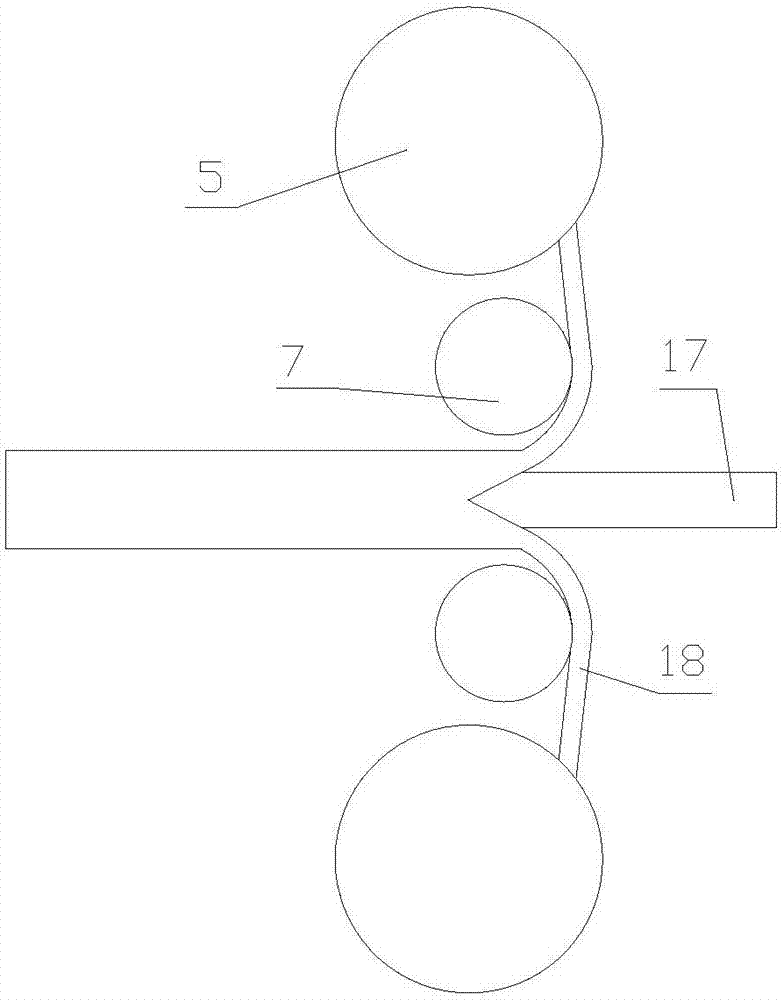

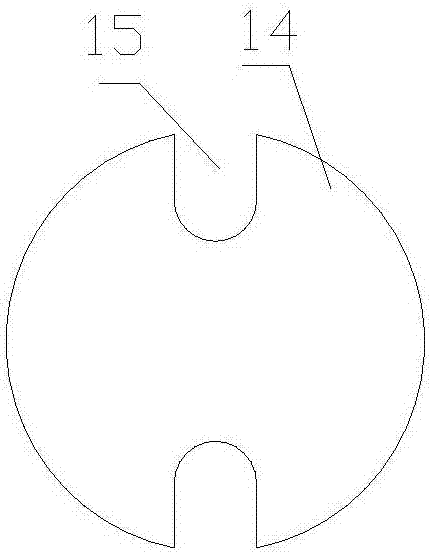

[0029] refer to figure 1 , 2 , 3:

[0030] A cable processing device proposed by the present invention includes a clamping mechanism, a processing mechanism, and a first recovery mechanism, and the processing mechanism is placed between the clamping mechanism and the first recovery mechanism;

[0031] The processing mechanism includes N processing units, the processing unit includes a crossbar 1, the crossbar 1 is provided with a cylinder 2, a connecting rod 3, the output end of the cylinder 2 is provided with a blade 4, and the cylinder 2 drives the blade 4 along the The radial displacement of the cable; the cylinder 2 is hinged to the crossbar 1, one end of the connecting rod 3 is hinged to the cylinder 2, and the other end is slidingly connected to the crossbar 1.

[0032] According to the diameter of the cable, the thickness of the insulating layer 18, the type of the cable, etc., the connecting rod 3 can be flexibly pushed, so that the blade 4 can destroy the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com