Induced-falling mining method for steep medium-thickness ore with hanging side containing unstable rock stratum

A mining method and steep inclination technology are applied in the field of induced caving mining of steeply inclined medium-thick ore bodies, which can solve the problems of low production efficiency and large ore dilution, and achieve the purpose of reducing ore loss and dilution, efficient mining, and waste reduction. Effect of stone mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

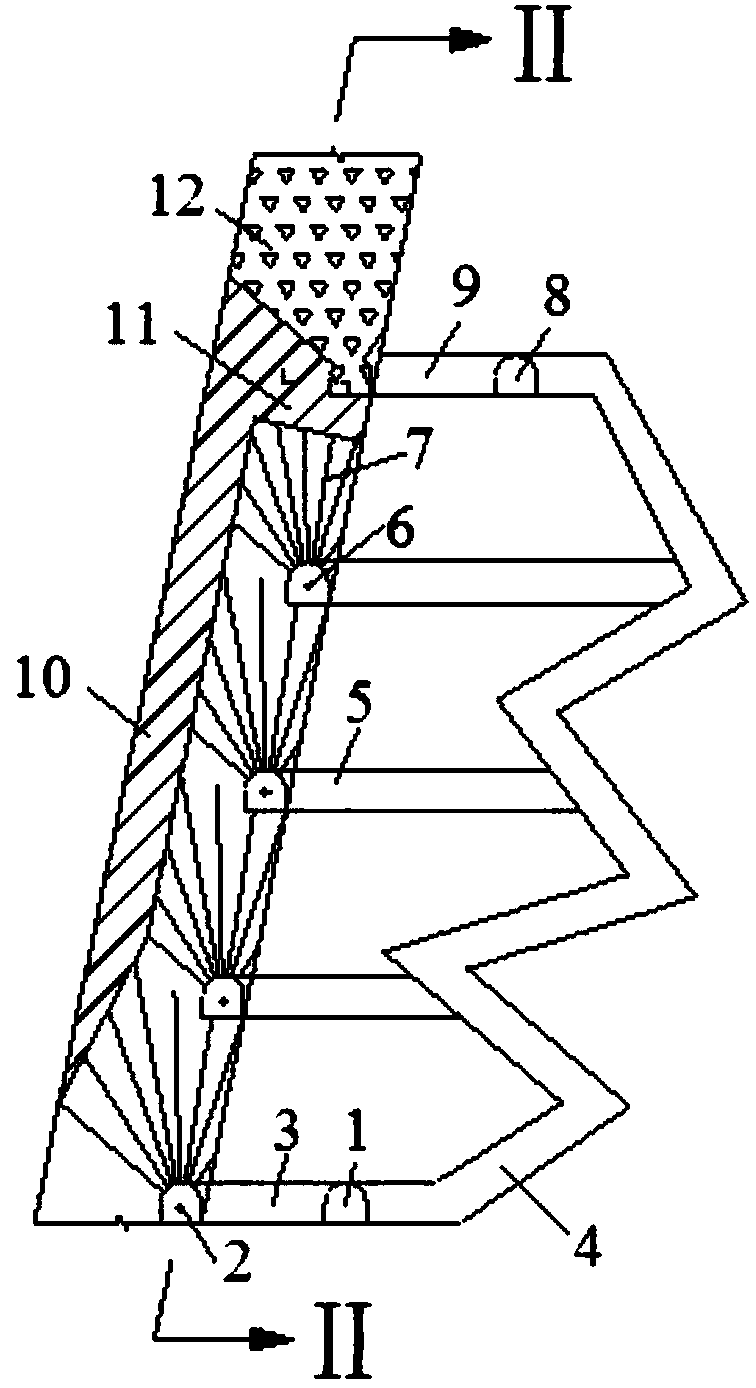

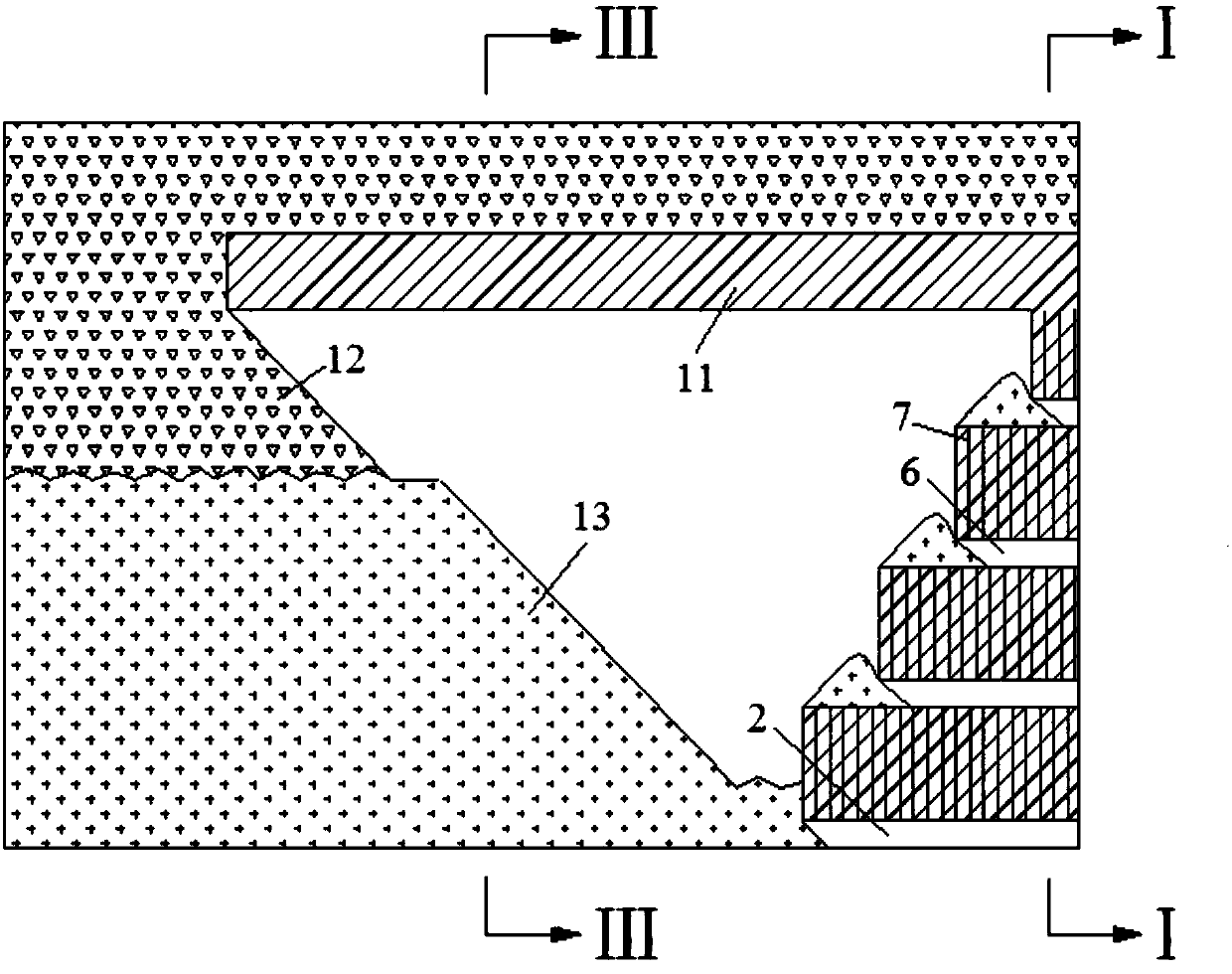

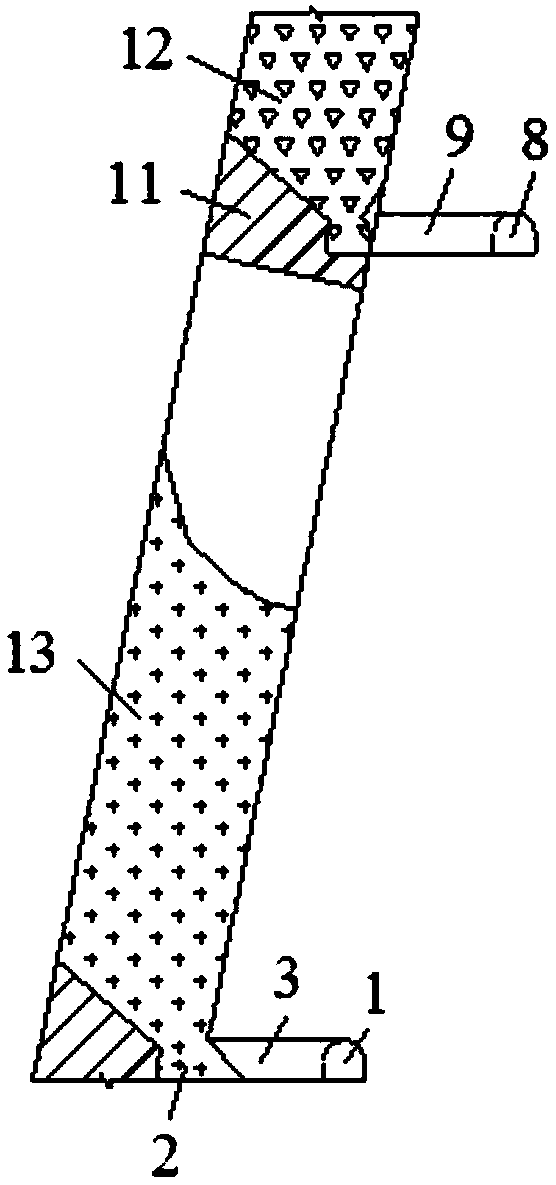

[0025] Such as Figure 1 ~ Figure 3 As shown, in this embodiment, the induced caving mining method of the steeply inclined medium-thick ore body containing unstable rock formations in the hanging wall is carried out according to the following steps:

[0026] (1) Pre-mining preparation: excavate the trench roadway 2 in the ore body of the vein-piercing roadway of the stage transportation horizontal development project, and excavate the ore-exit roadway 1 outside the ore body of the vein-piercing roadway. The ore exit roadway 1 is vertically excavated toward the trench roadway 2 and the ore exit crossing 3 is generally 8-12m apart; at the same time, the connecting road 5 of each segment is excavated from the ramp 4, and after the connecting road 5 is excavated through the ore body , excavate the rock-drilling roadway 6 of each mining section in the ore body, and the height of each mining section is 12-18m, generally about 15m;

[0027] (2) Mining operation: during mining, only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com