Method for preparing longitudinal heterojunctions of single-layer transition metal chalcogenides by no-glue transfer

A transition metal chalcogenide, compound technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problem of inability to adjust the relative angle of vertical heterojunction, transition metal chalcogenide doping, experimental parameters Sensitivity and other issues, to promote research and application, prevent damage and doping, and solve the effect of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

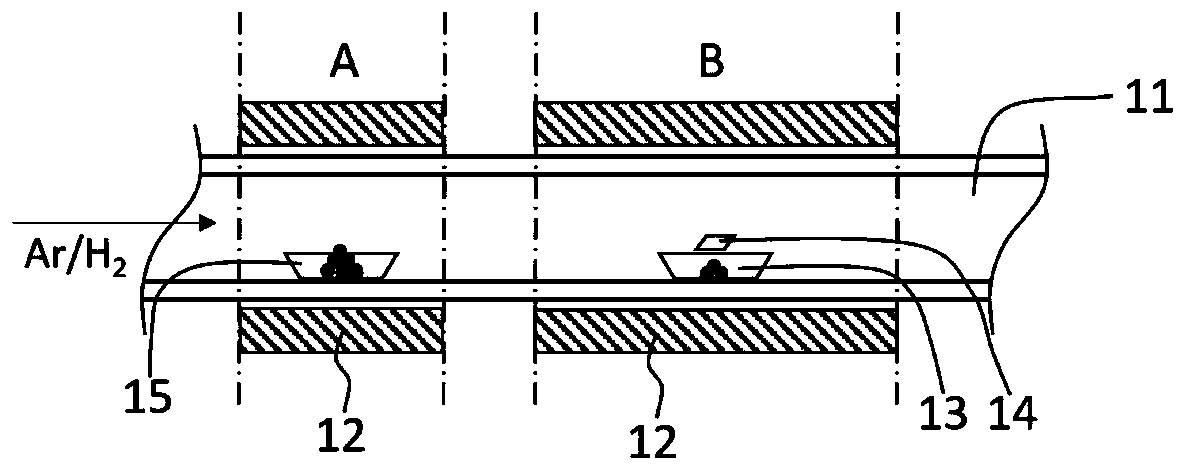

[0046] Example 1, MoS is prepared by chemical vapor deposition 2 as an example.

[0047] Place 100mg of sulfur powder in the first quartz boat 15, place 0.5mg of transition metal oxide powder and molten salt powder mixture in the second quartz boat 13, the transition metal oxide selected in this embodiment is MoO 3 , the usage amount is about 0.3 mg, the selected molten salt is NaCl, and the usage amount is about 0.2 mg. 14 is the growth film substrate, that is, the substrate used in the growth and preparation of transition metal chalcogenides by chemical vapor deposition. In this embodiment, SiO 2 / Si as the substrate. Place the two quartz boats in the quartz tube 11 lined with the tube furnace insulation material 12, place them in the tube furnace, and heat them to 650°C through the tube furnace, so that the powder in the quartz boats is heated and evaporated into the gas phase, and then Under the transport of the carrier gas Ar, the evaporated gas phases are mixed and ch...

Embodiment 2

[0049] Example 2, MoSe is prepared by chemical vapor deposition 2 as an example.

[0050] 50mg of selenium powder is placed in the first quartz boat 15, and 1.5mg of transition metal oxide powder and molten salt powder mixture is placed in the second quartz boat 13. The transition metal oxide selected in this embodiment is MoO 3 , the usage amount is about 1.0 mg, the selected molten salt is NaCl, and the usage amount is about 0.5 mg. 14 is the growth film substrate, that is, the substrate used in the growth and preparation of transition metal chalcogenides by chemical vapor deposition. In this embodiment, glass is used as the substrate. Place the two quartz boats in the quartz tube 11 lined with the tube furnace insulation material 12, place them in the tube furnace, and heat them to 900°C through the tube furnace, so that the powder in the quartz boats is heated and evaporated into the gas phase. Carrier gas Ar / H 2 Under the transport, the evaporated gas phase is mixed an...

Embodiment 3

[0052] Embodiment 3, prepare WS with chemical vapor deposition 2 as an example.

[0053] Place 300mg of sulfur powder in the first quartz boat 15, place 15mg of transition metal oxide powder and molten salt powder mixture in the second quartz boat 13, the transition metal oxide selected in this embodiment is WO 3 , the usage amount is about 10 mg, the selected molten salt is NaI, and the usage amount is about 5 mg. 14 is the growth film substrate, that is, the substrate used in the growth and preparation of transition metal chalcogenides by chemical vapor deposition. In this embodiment, SiO 2 / Si as the substrate. Place the two quartz boats in the quartz tube 11 lined with the insulation material 12 of the tube furnace, place them in the tube furnace, and heat them to 850°C through the tube furnace, so that the powder in the quartz boats is heated and evaporated into the gas phase. Carrier gas Ar / H 2 Under the transport, the evaporated gas phase mixes and undergoes a chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com