Patents

Literature

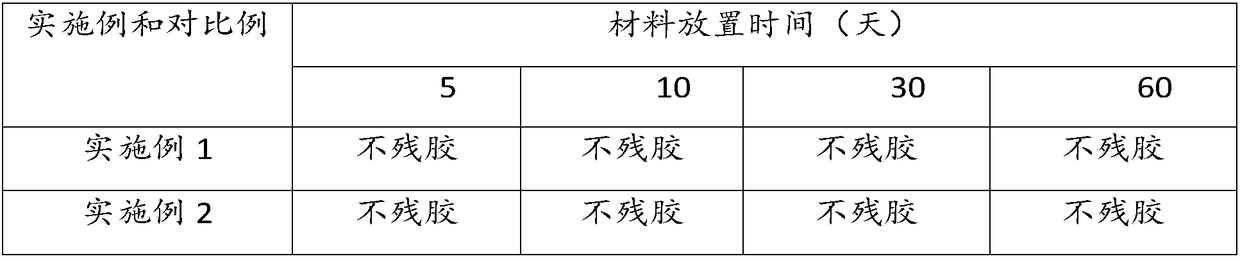

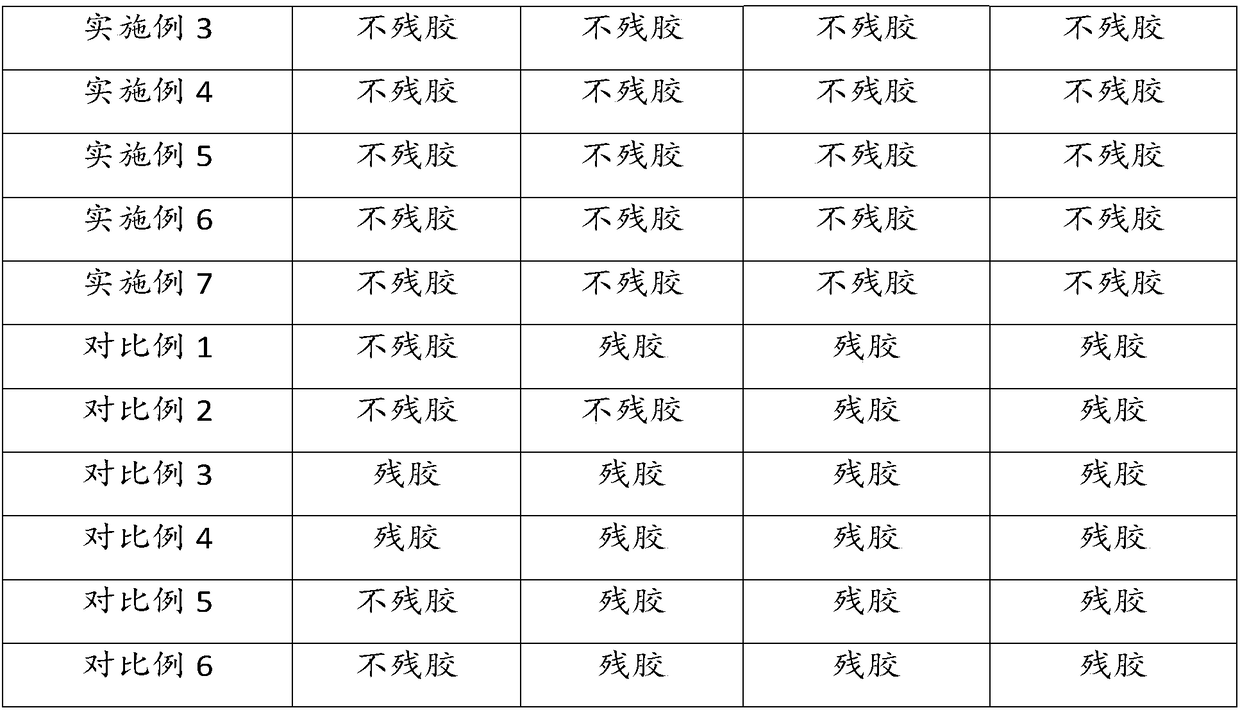

31results about How to "Solve the problem of residual glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

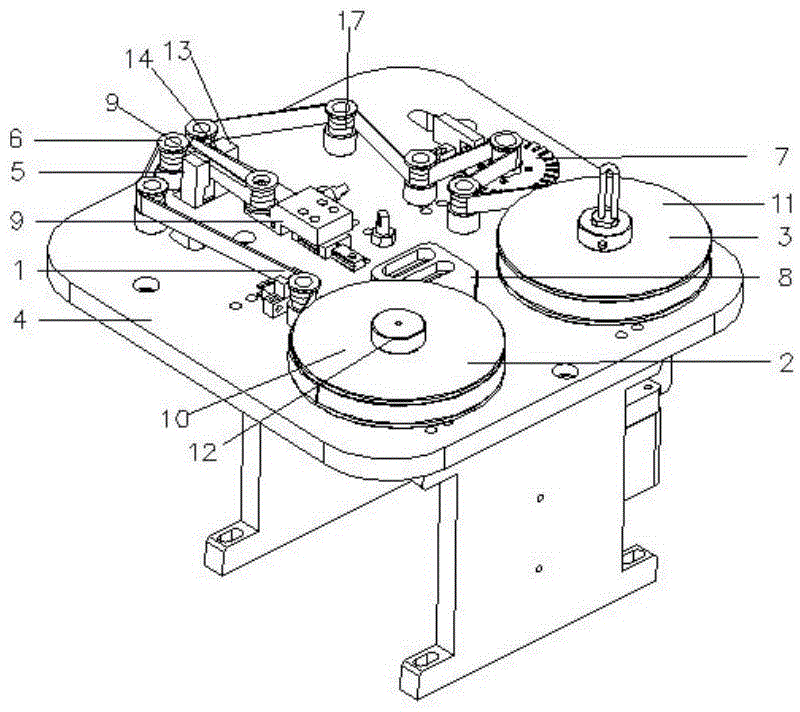

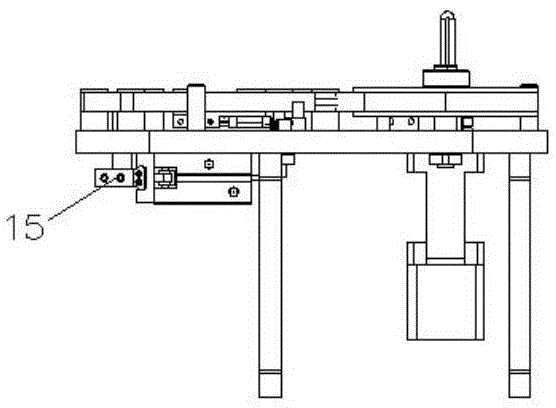

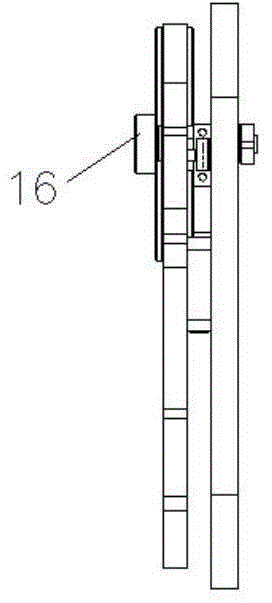

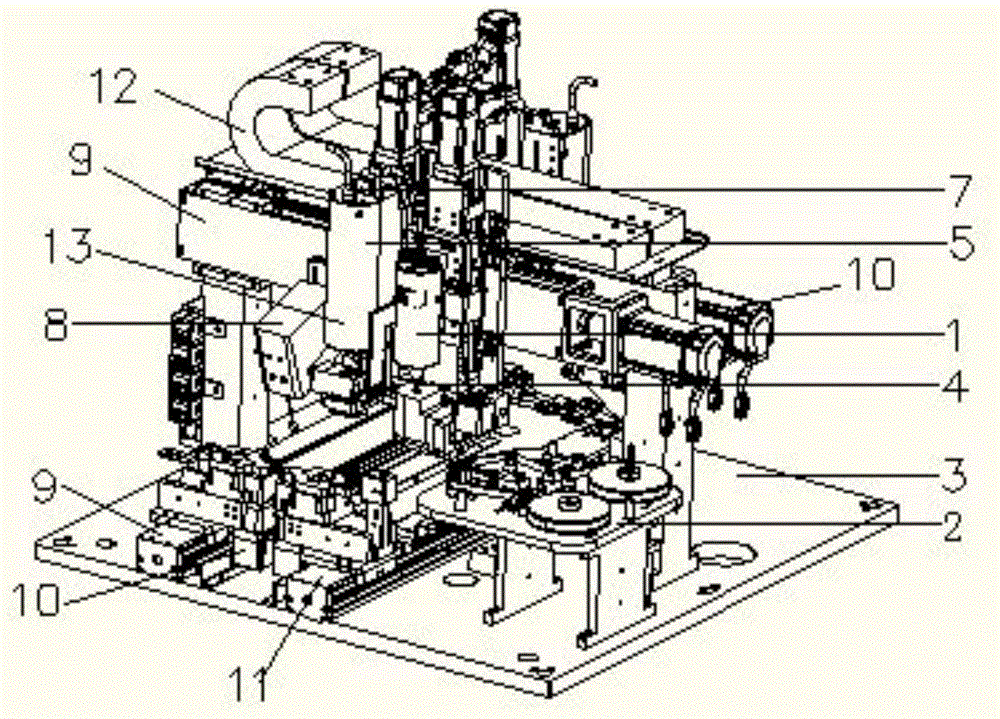

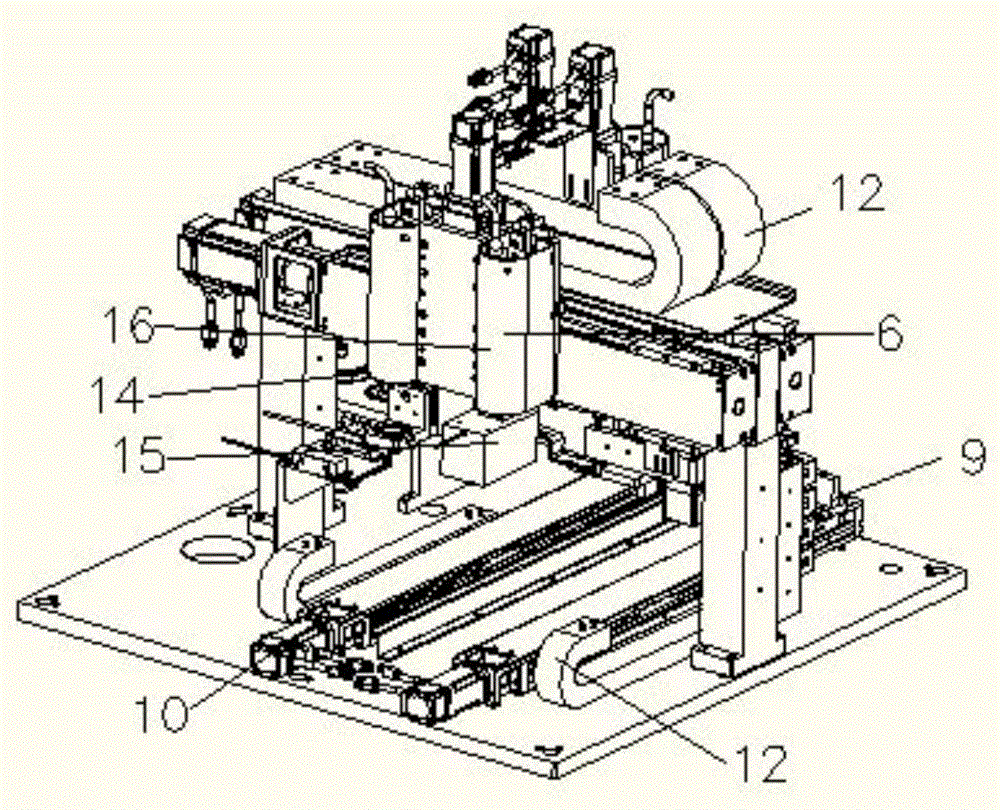

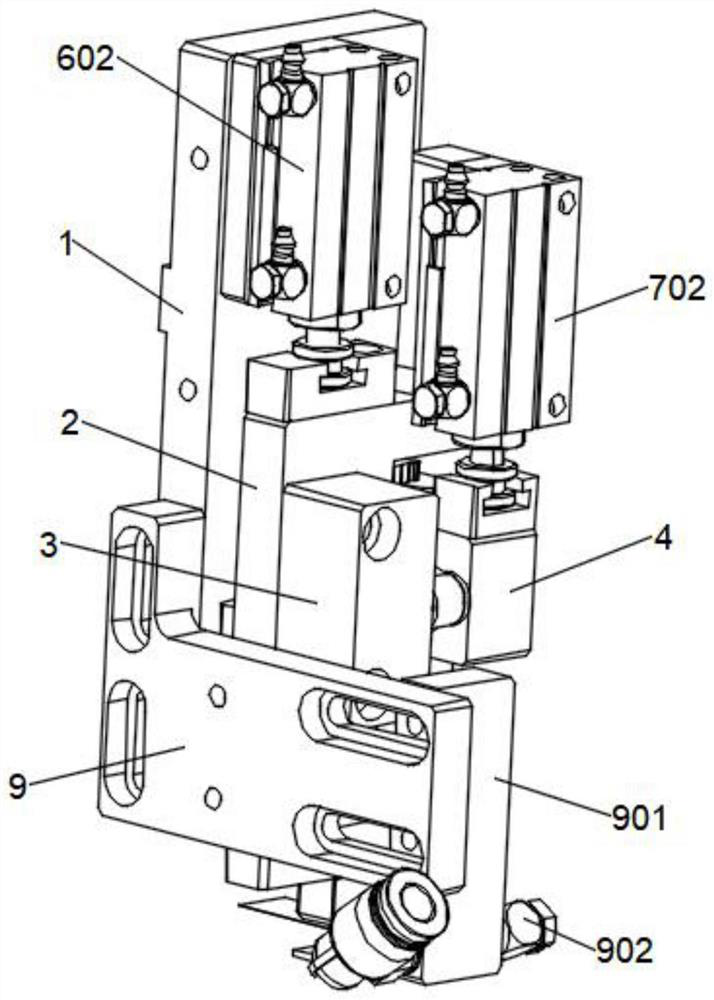

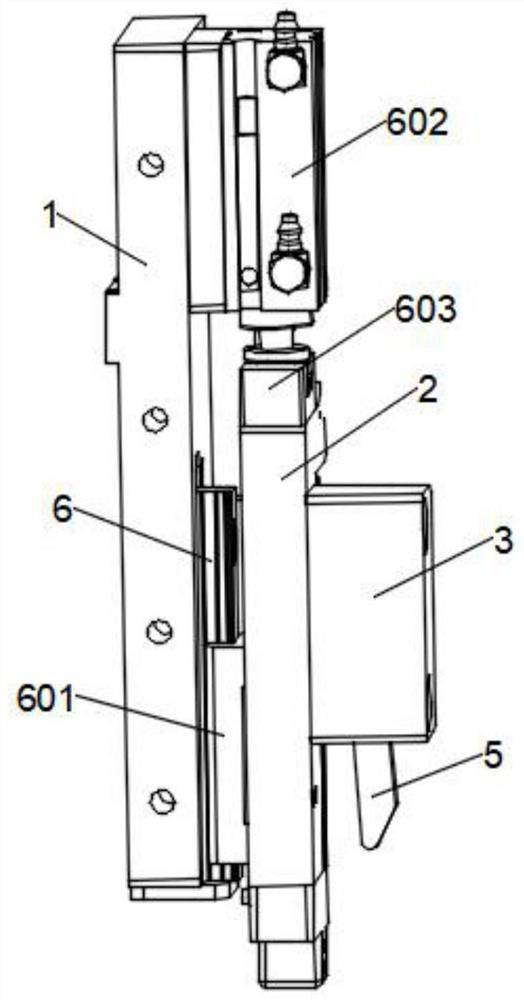

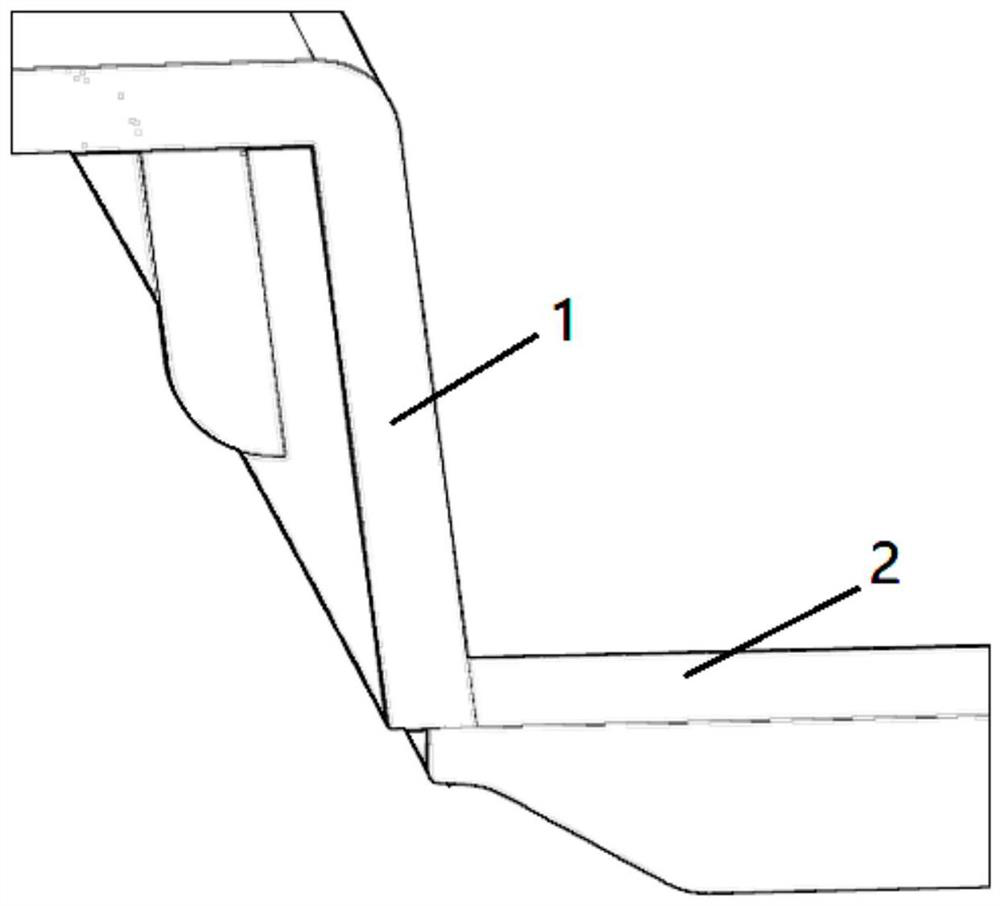

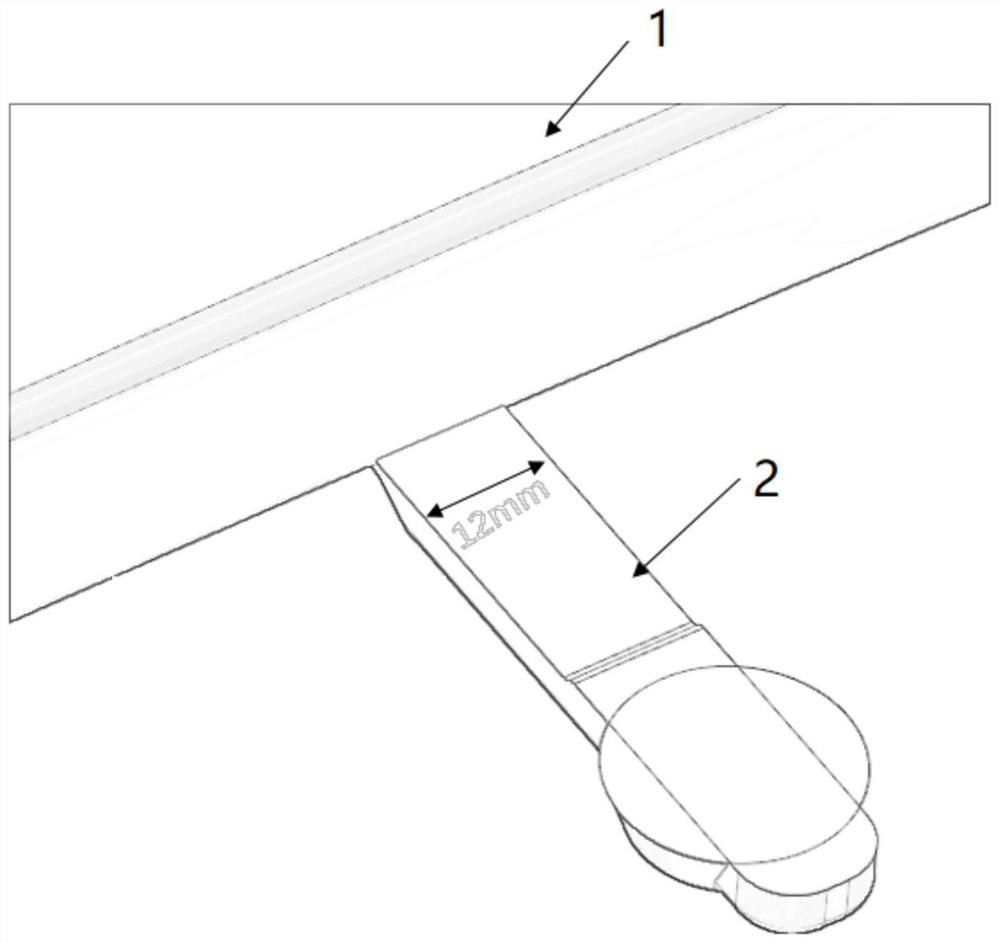

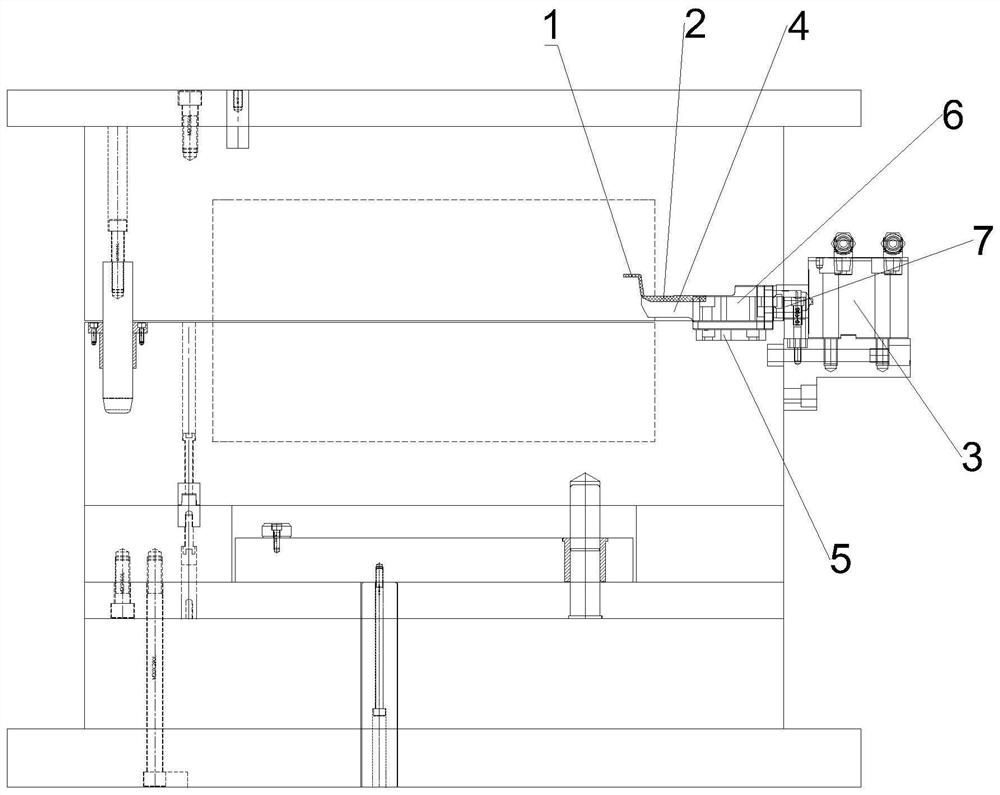

Frictioning machine

ActiveCN104889028AClose contactSolve the problem of residual glueLiquid surface applicatorsCoatingsEngineeringMechanical engineering

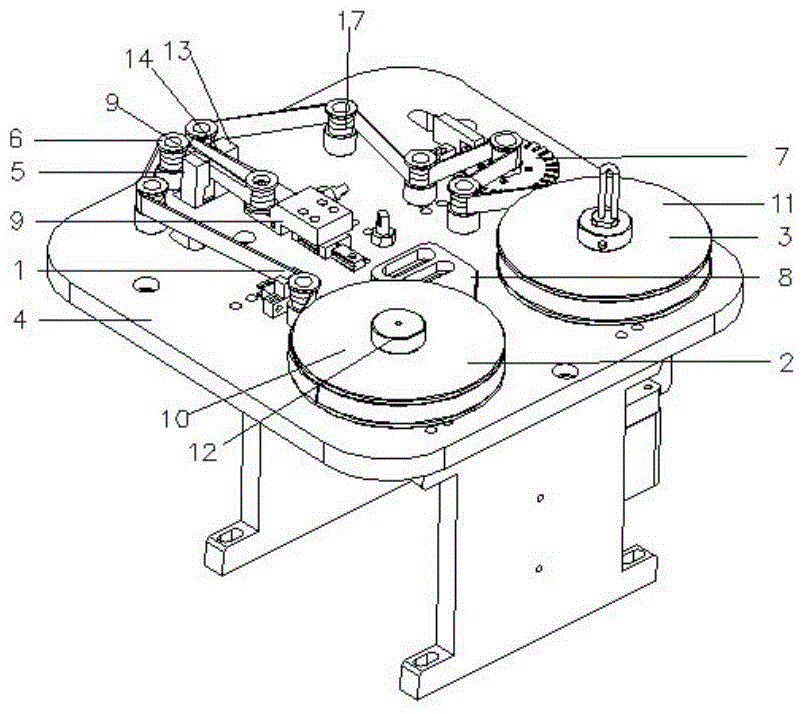

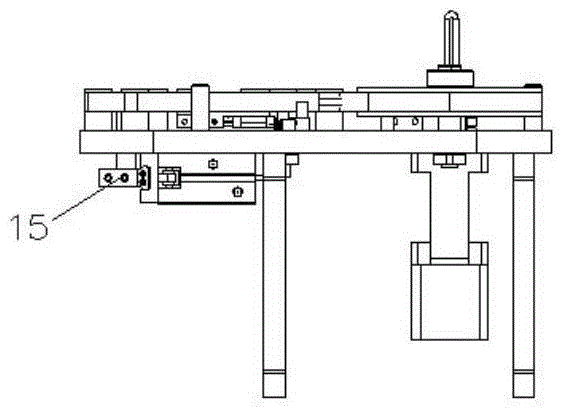

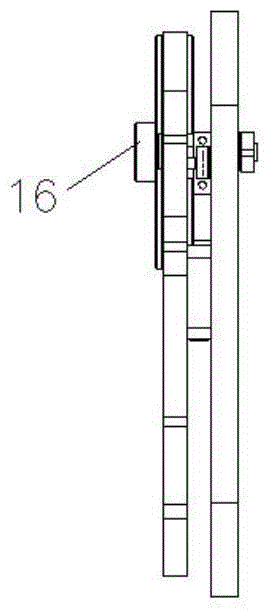

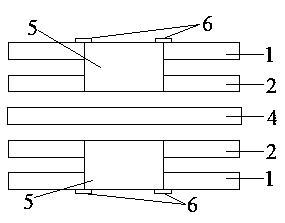

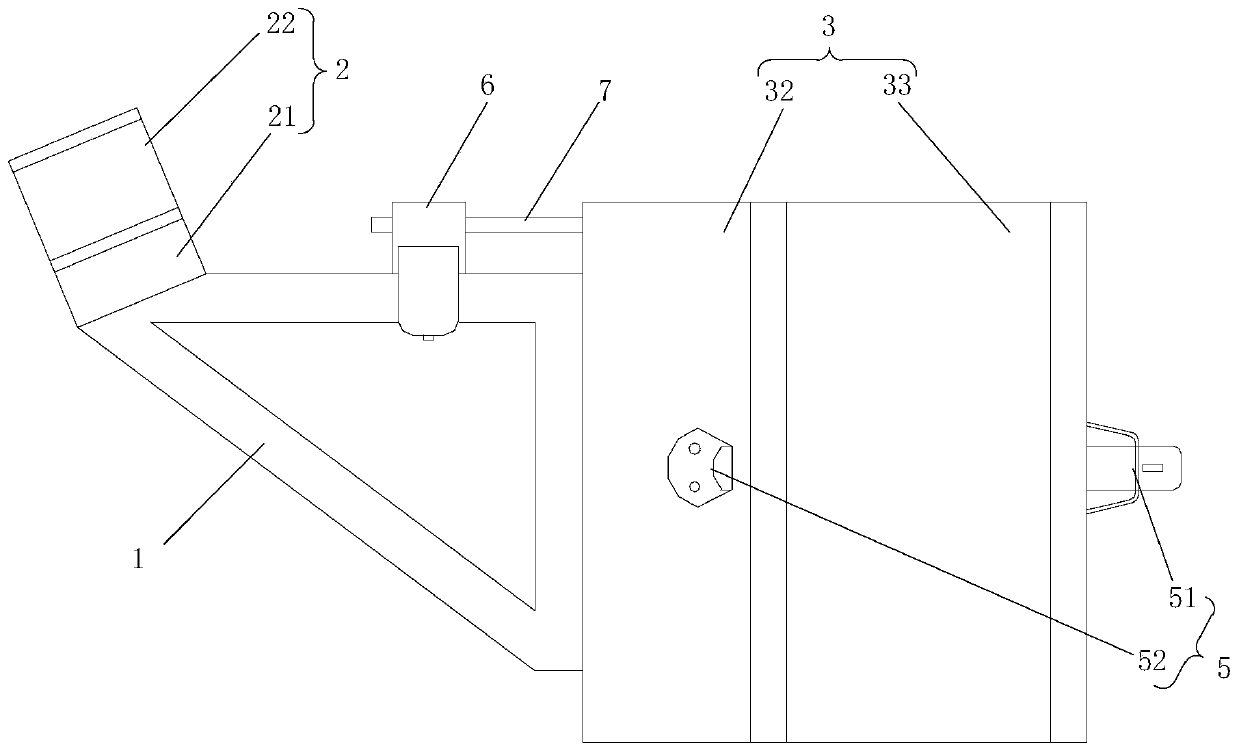

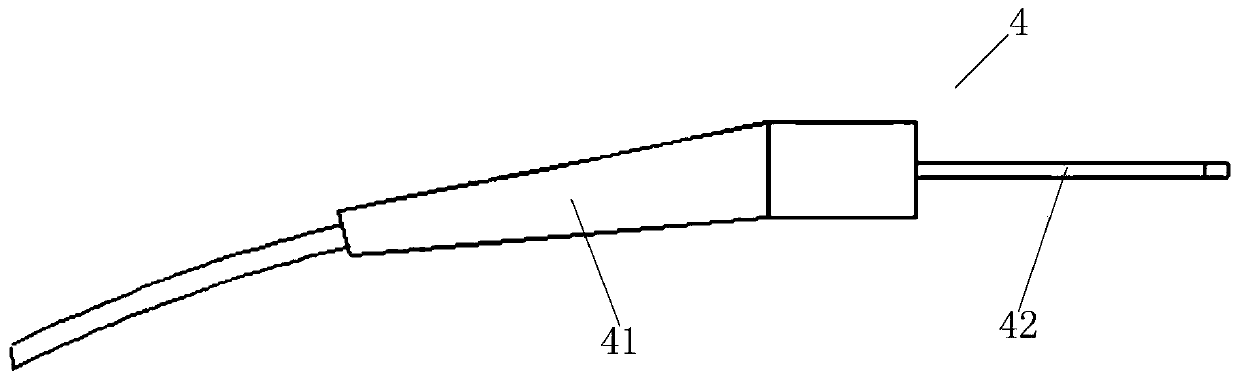

The invention discloses a frictioning machine, comprising a material strip, a feeding mechanism, a material recovering mechanism and a pedestal, wherein the material strip is fixed on the feeding mechanism and is conveyed by the feeding mechanism to allow the material strip to be contact with a to-be-frictionated part, the material strip is recovered by the material recovering mechanism after frictioning, and the feeding mechanism and the material recovering mechanism are arranged on the pedestal. Through the feeding mechanism, the material strip and the material recovering mechanism, the material strip closely contacts with the to-be-frictionated part and gum on the to-be-frictionated part is cleaned, so the problem of residual gum is overcome.

Owner:SUZHOU RS TECH

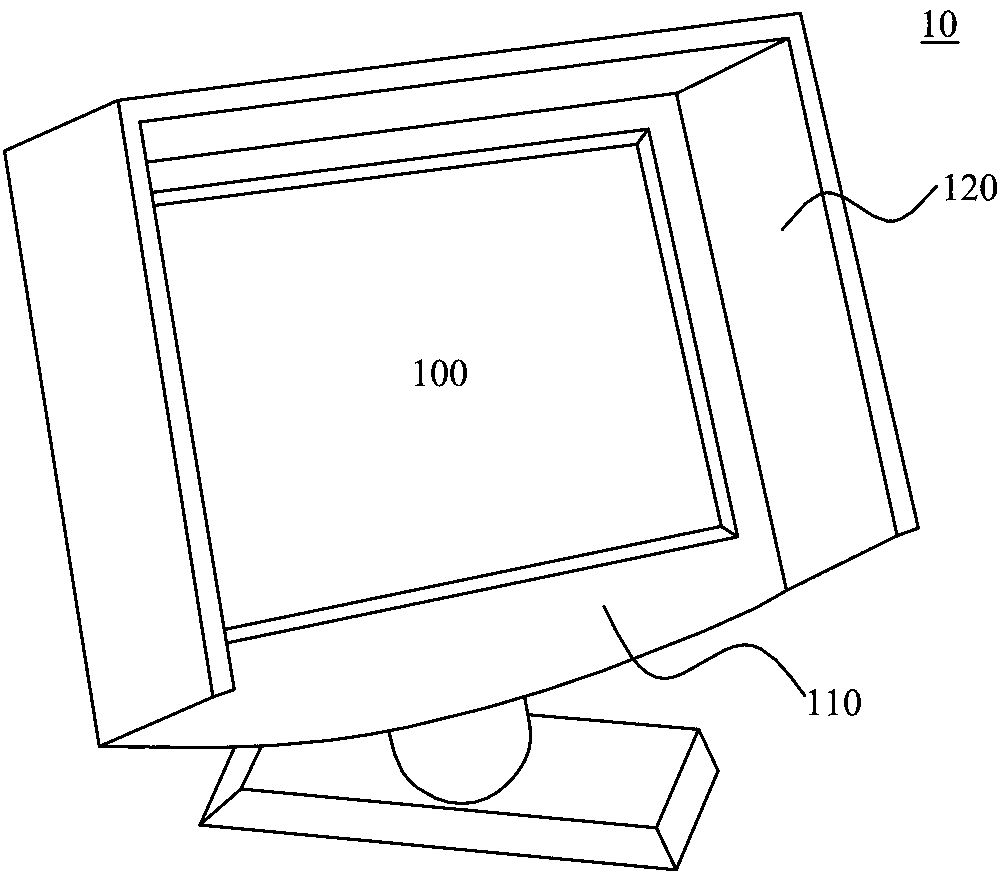

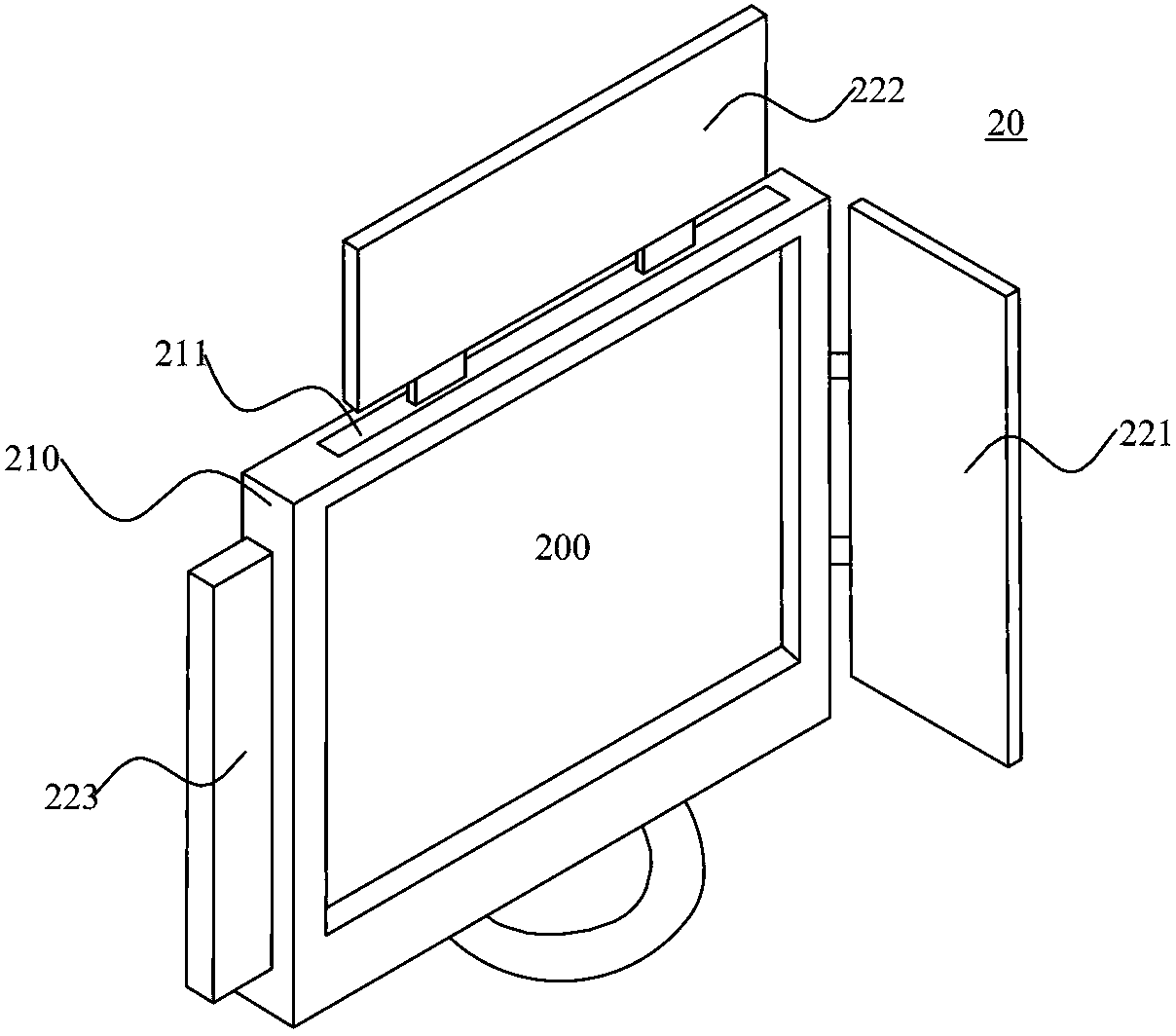

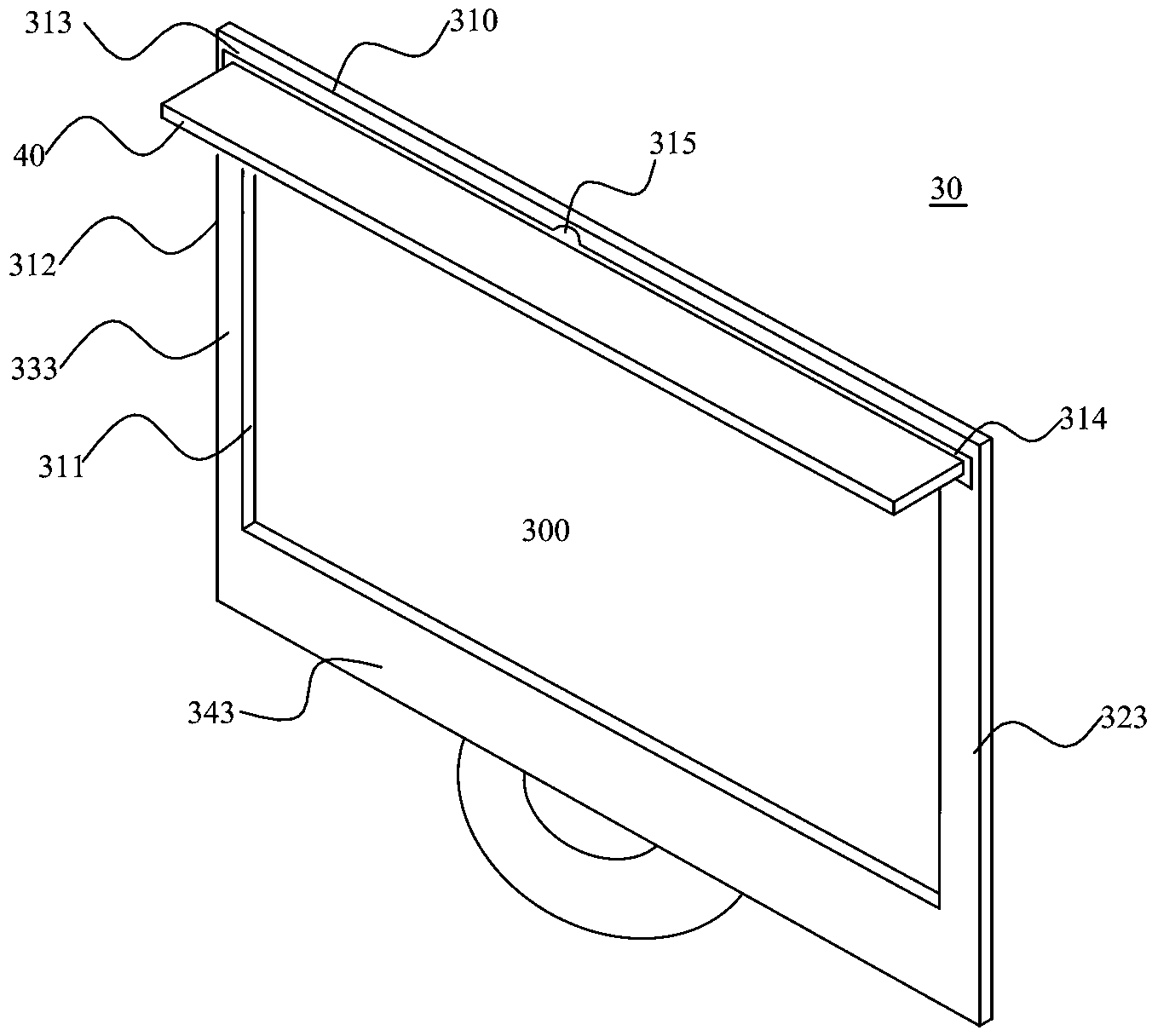

Display and display device

InactiveCN103226916AOvercome the problem of not displaying properlySimple structureCasings/cabinets/drawers detailsIdentification meansDisplay deviceEngineering

The invention provides a display and a display device. The display comprises a display screen, a casing and a flexible shading device. When not in use, the flexible shading device is accommodated inside the casing through a first mounting groove; and when in use, the flexible shading device protrudes from and extends out of the casing through the first mounting grove to shade light. Compared with the prior art, the display, provided by the invention is provided with the flexible shading device, and the flexible shading device has a simple structure, and can be accommodated inside the casing of the display after being folded, so that the problems of accommodation, adhesive residue or once paste of a conventional external hanging shading device are solved. Since the flexible shading device is flexible, and can be coiled or bent inside the casing of the display after being folded, the required accommodation space is reduced considerably, and the flexible shading device is better suitable for a narrow-frame display.

Owner:QISDA SUZHOU +1

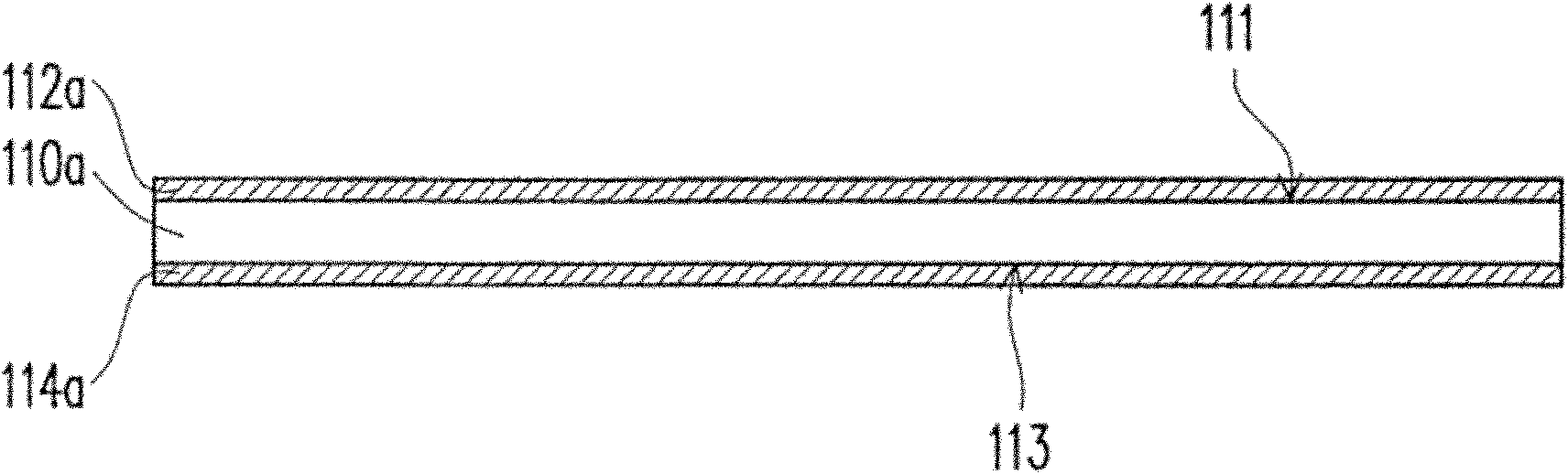

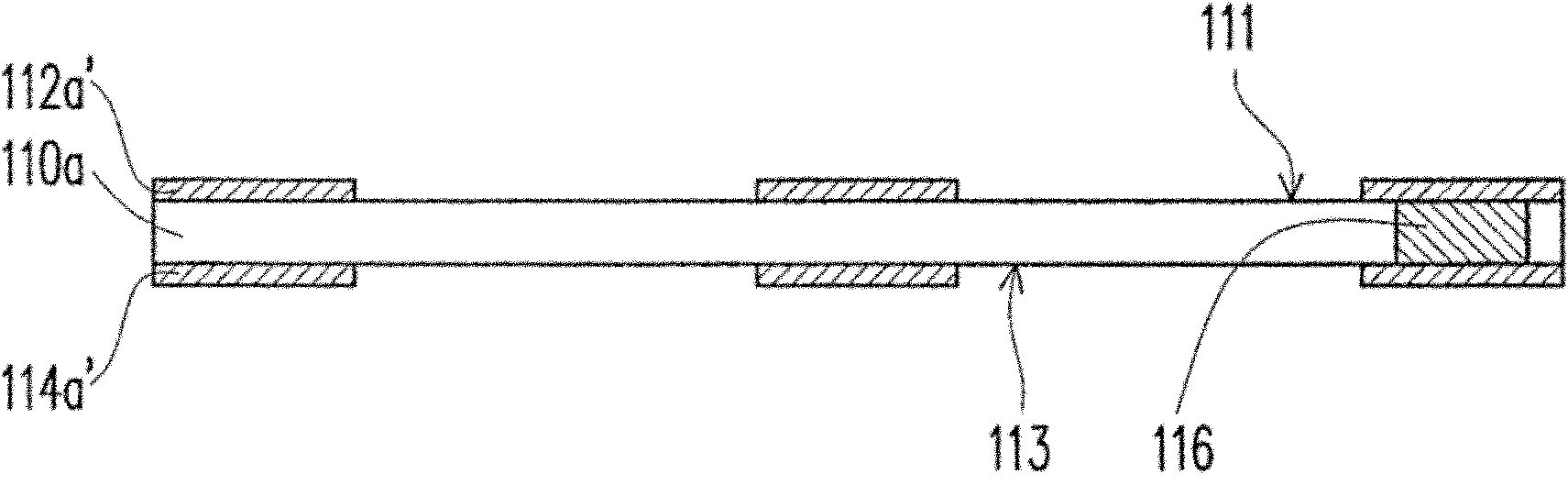

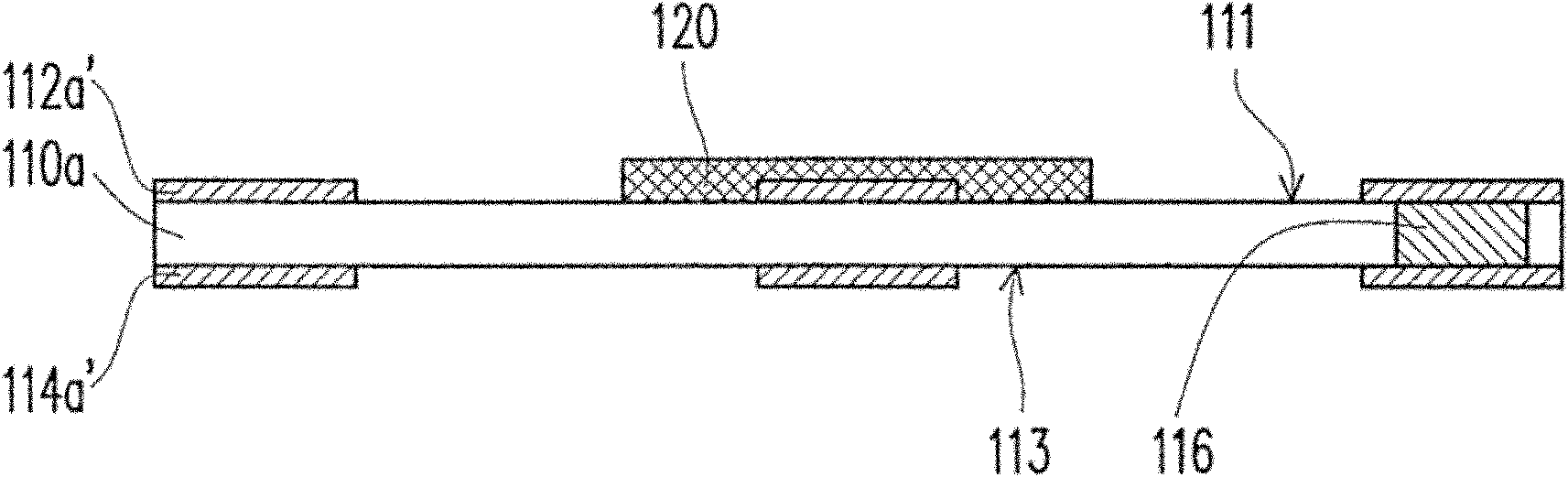

Circuit board and manufacturing method thereof

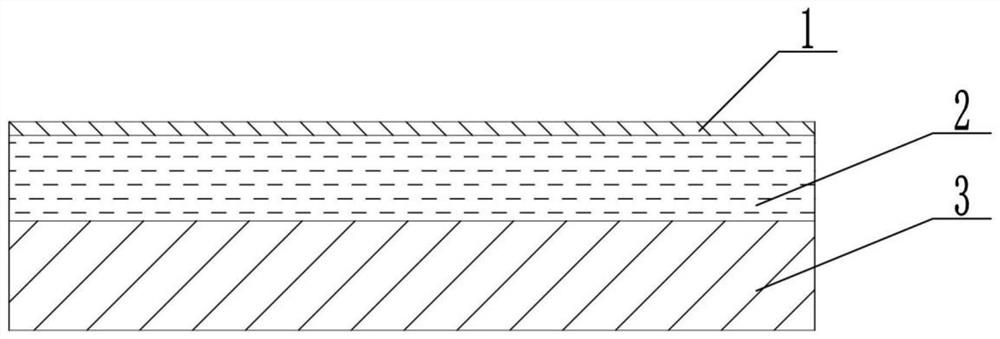

InactiveCN102487578AImprove joint reliabilityReduce assembly thicknessMultilayer circuit manufactureTectorial membraneEngineering

The invention provides a circuit board and a manufacturing method thereof. The method comprises the following steps of: providing a base layer, wherein a first patterning line layer, a second patterning line layer and at least one conductive through hole structure connected with the first patterning line layer and the second patterning line layer are formed on the base layer; configuring at least one protection film on the base layer, wherein the first patterning line layer is partly covered by the protection film; laminating a first added layer line structure onto the protection film and part of the first patterning line layer, wherein the first added layer line structure is provided with at least one pre-removed block, and the pre-removed block is arranged, corresponding to the protection film; laminating a second added layer line structure onto the second patterning line layer; removing the pre-removed block to form at least one notch capable of ensuring the protection film to be exposed out; and removing the protection film to expose part of the first patterning line layer positioned below the protection film.

Owner:UNIMICRON TECH CORP

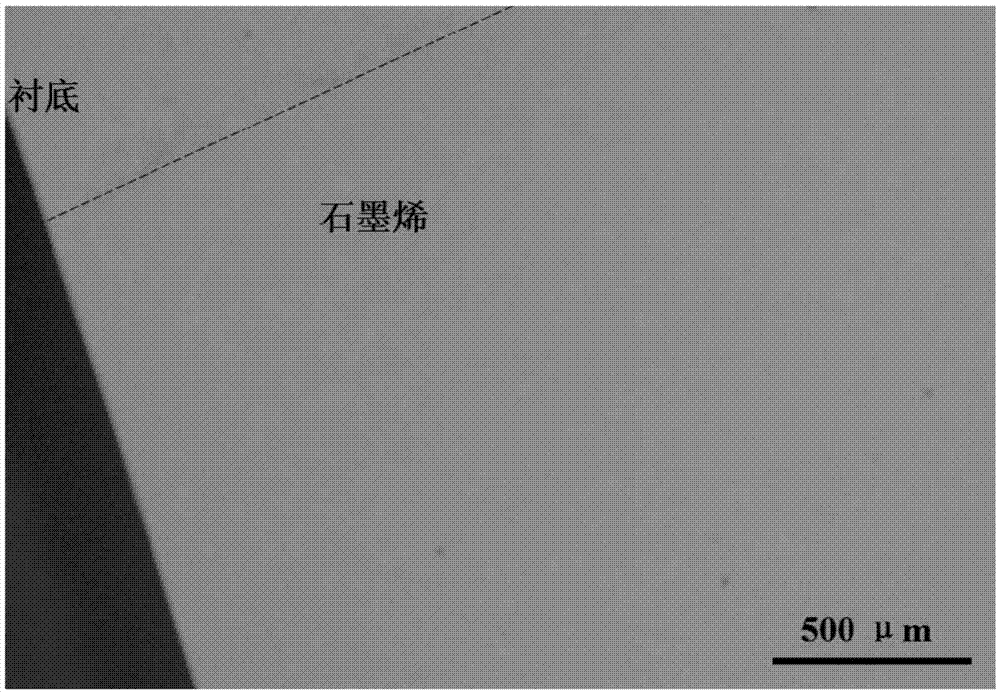

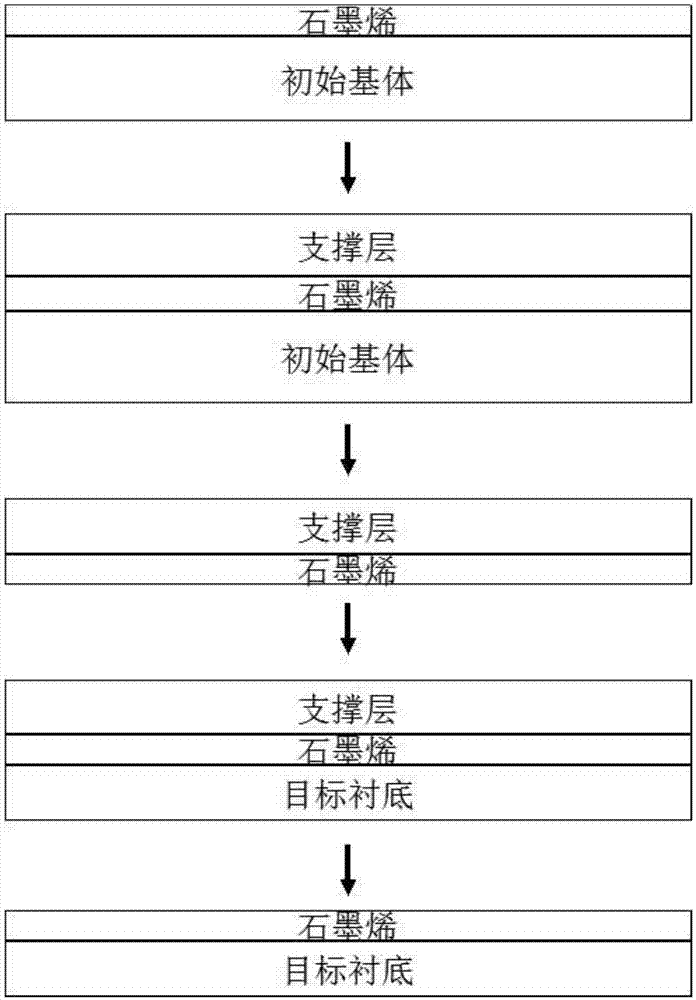

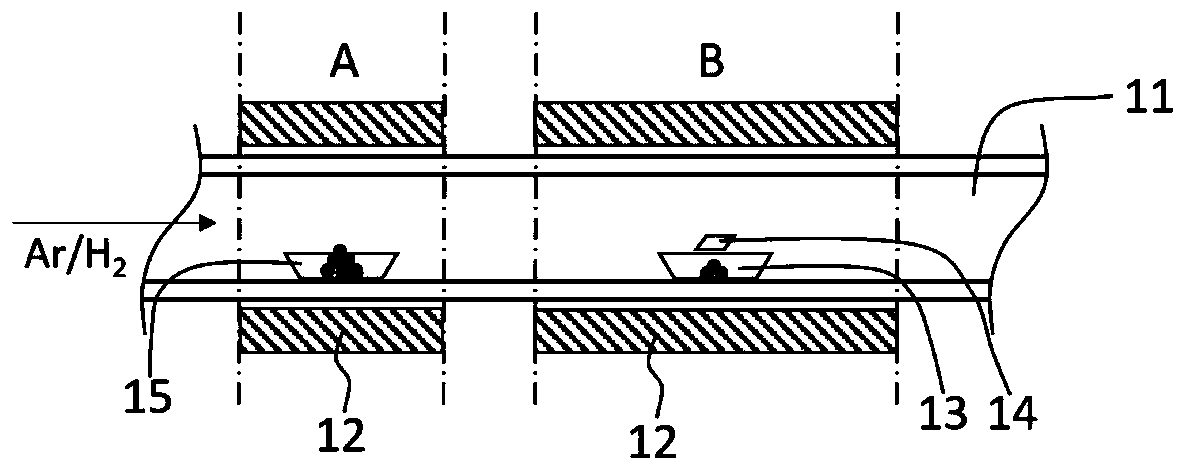

Method for transferring graphene based on sublimation method

The invention discloses a method for transferring graphene. According to the method, a substance which is easily sublimated is utilized as a supporting layer for transferring the graphene; first, through heating the substance which is easily sublimated, the substance is desublimated to form a compact supporting layer on the surface of the graphene growing on an initial matrix, then, the initial matrix is removed and the graphene / supporting layer is transferred to a target substrate, and afterwards, the supporting layer is sublimated. In comparison with adhesive residue problems existing in existing PMMA (Polymethyl Methacrylate) method and PDMS (Polydimethylsiloxane) method and problems that a hot padding method and a heat release adhesive tape method have relative high requirements on the flatness and the adhesiveness of the target substrate, and the like, according to the method, the substance which is easily sublimated is used as the supporting layer; the transfer process is simpler, more convenient and quicker; the large-area, damage-free and adhesive-residue-free transfer of the graphene to any target substrate can be realized; the application of the graphene to the fields of flexible electronics, organic nanoelectronics, organic solar cells, organic sensor aspects, organic high-performance micro-nano electronic devices, organic-material energy storage and the like is greatly expanded.

Owner:PEKING UNIV

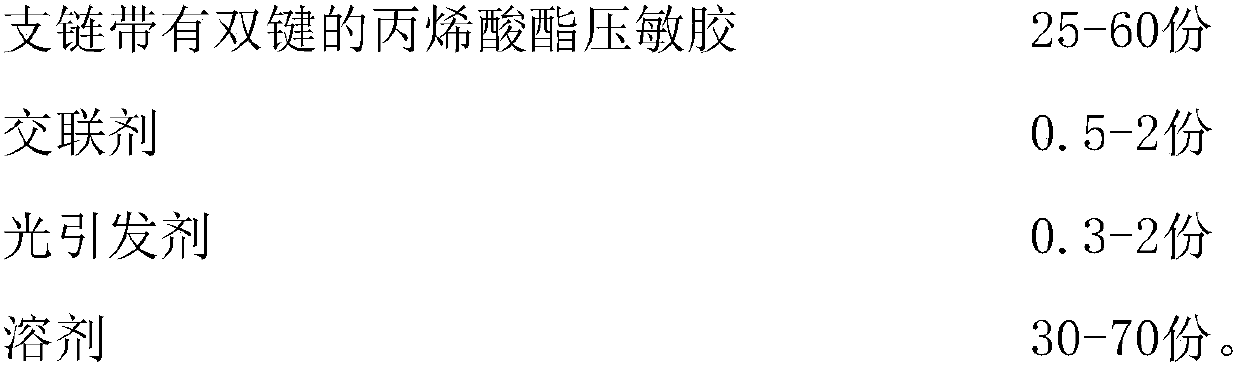

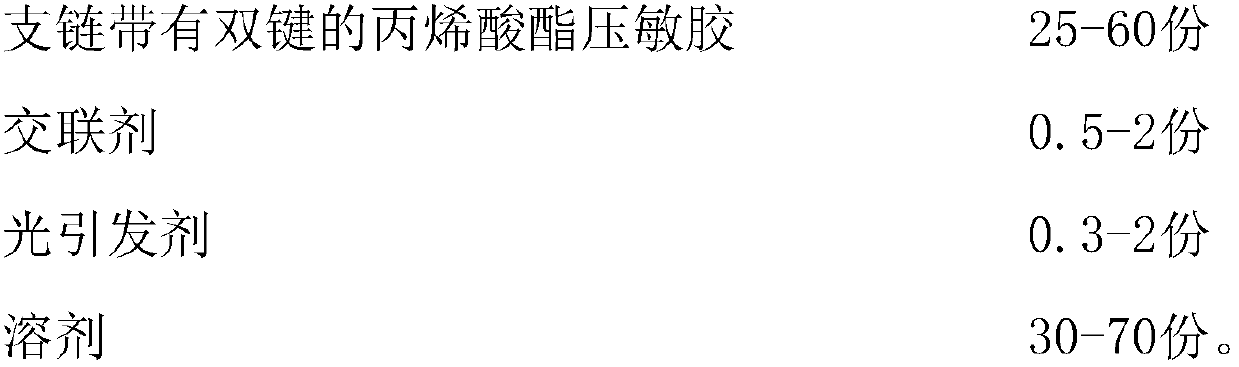

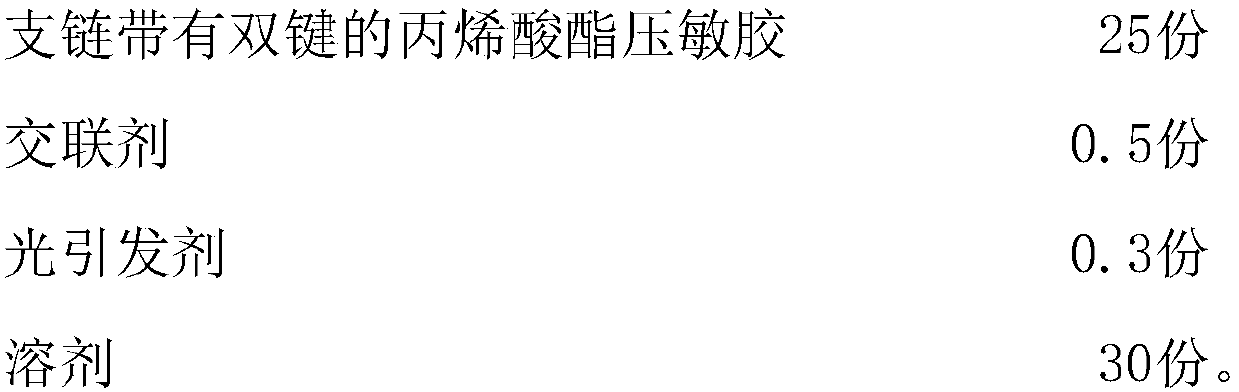

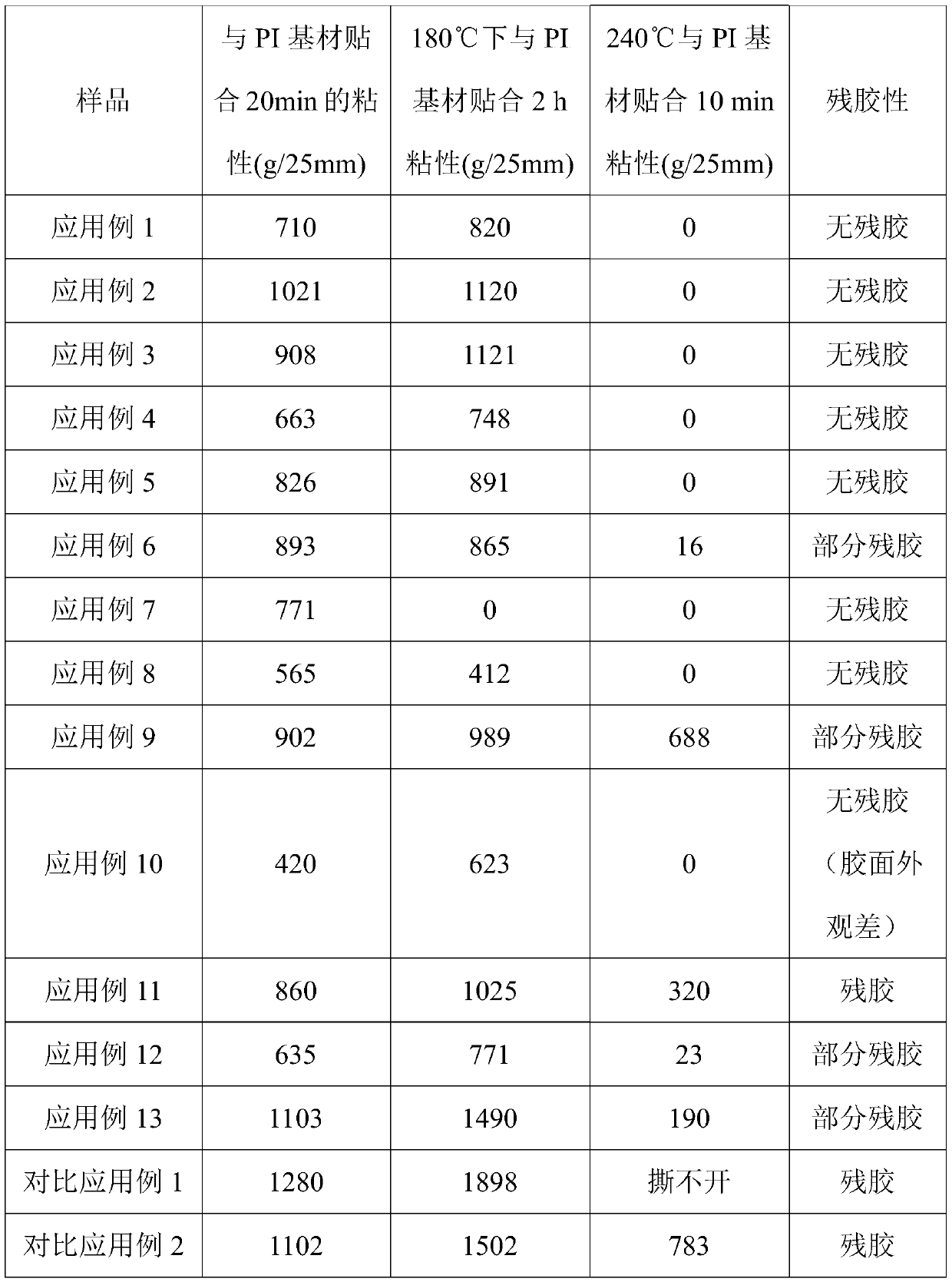

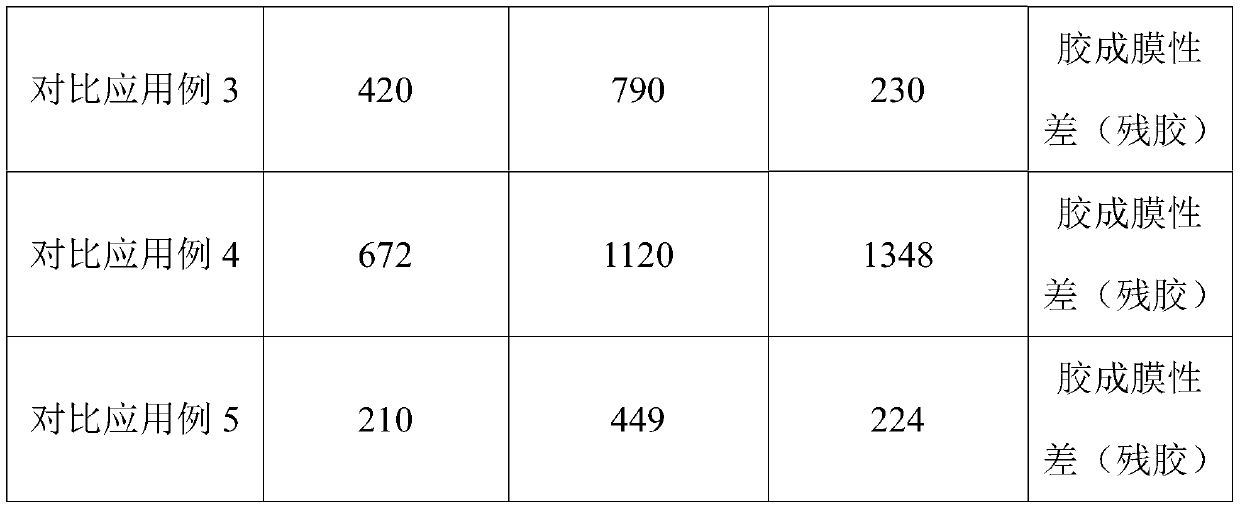

UV visbreaking protection film for lithium battery packaging, and preparation method thereof

PendingCN110093115ASimple coating processSuitable for mass productionFilm/foil adhesivesEster polymer adhesivesTectorial membraneEconomic benefits

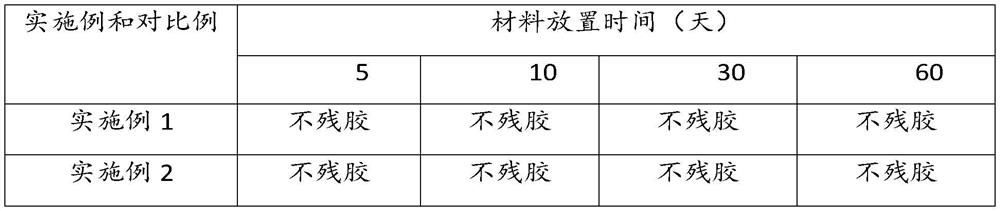

The invention relates to the technical field of protection film adhesive tapes, and concretely to a UV visbreaking protection film for lithium battery packaging, and a preparation method thereof. TheUV visbreaking protection film for lithium battery packaging comprises a substrate film, a UV visbreaking layer and a release film which are sequentially arranged, the UV visbreaking layer is a layerof an acrylate pressure sensitive adhesive containing a double bond in the branch chain, the UV visbreaking layer is obtained by drying a UV visbreaking glue, and the UV visbreaking glue comprises theacrylate pressure sensitive adhesive containing the double bond in the branch chain, a crosslinker, a light Initiator and a solvent. The UV visbreaking protection film realizes UV light visbreaking with only a single glue, so the problems of low production efficiency and residual glue in the use process of a traditional protection film are solved, and the problem of non-stability of existing UV visbreaking adhesives is also solved. The preparation method has a simple process, do not need harsh production conditions or devices, is especially suitable for large-scale mass production, and has great economic benefits.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

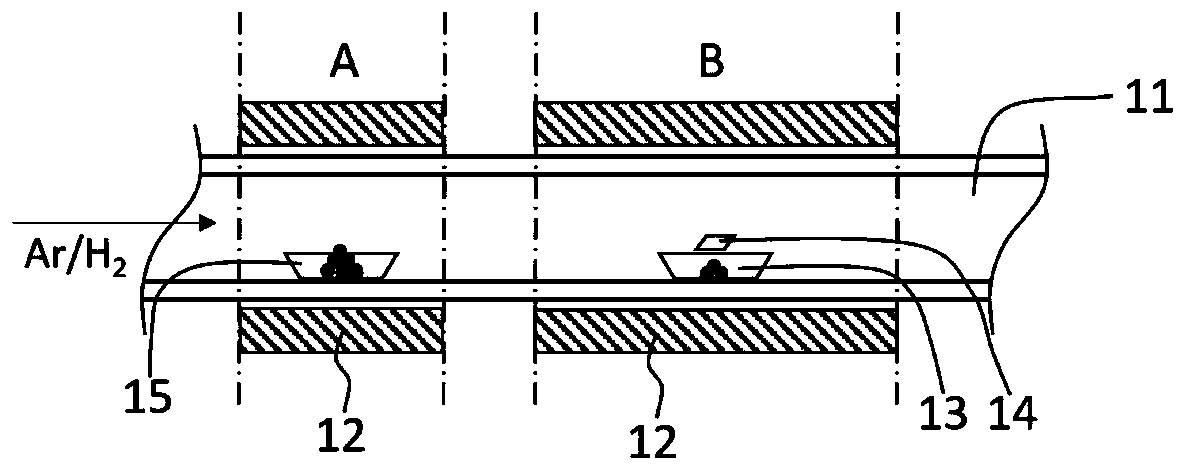

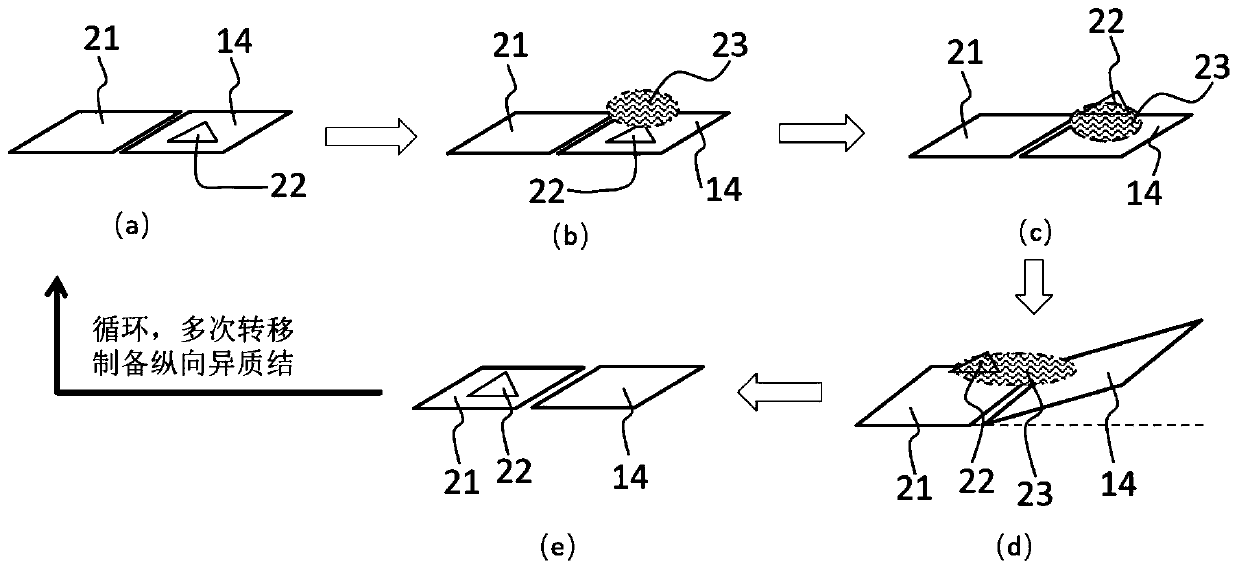

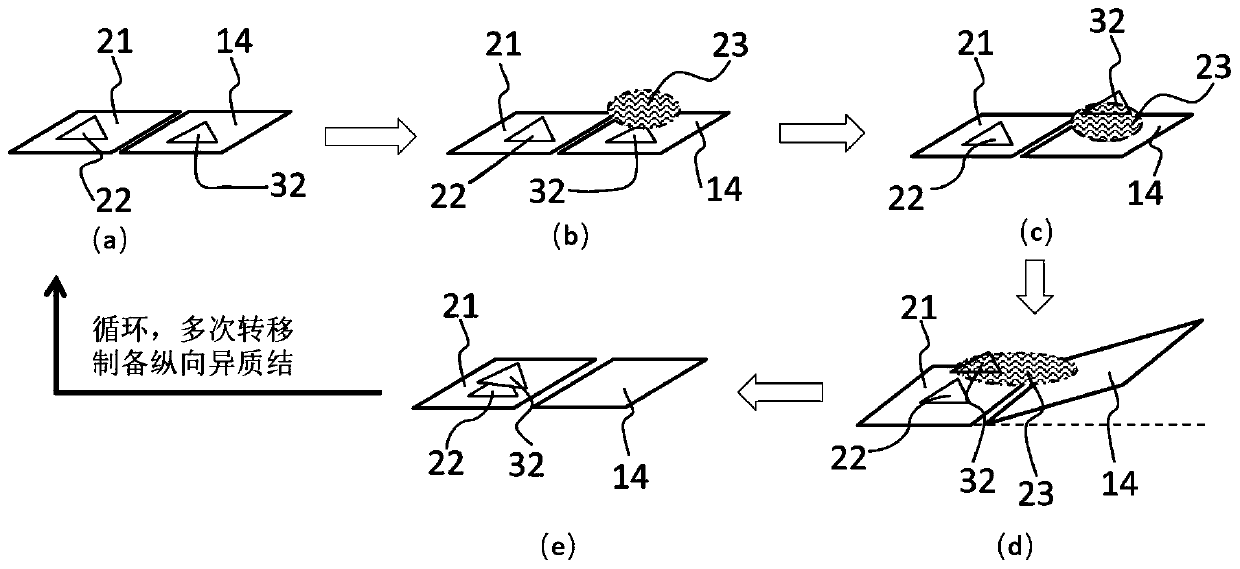

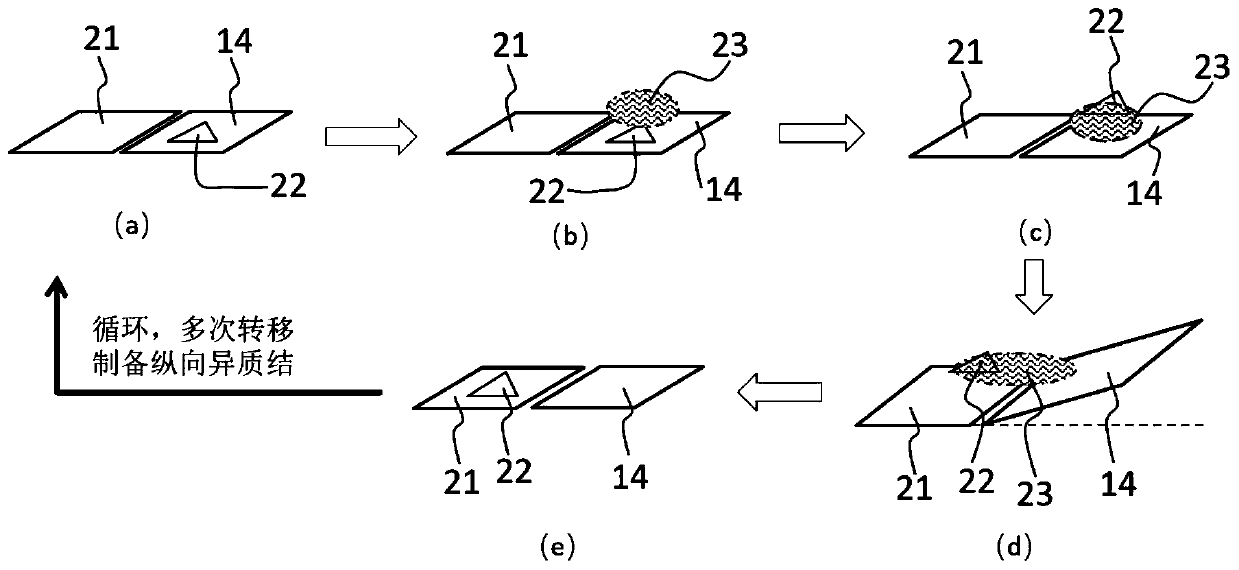

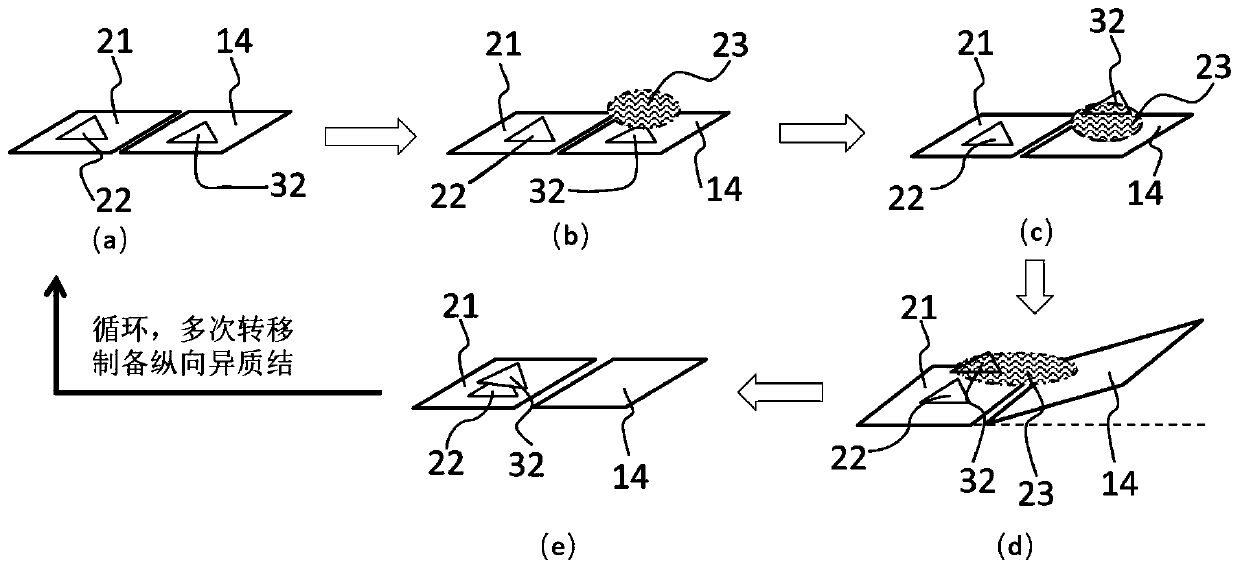

Method for preparing longitudinal heterojunctions of single-layer transition metal chalcogenides by no-glue transfer

ActiveCN110241400ASolve the residual glueProtection against sabotage and dopingChemical vapor deposition coatingIonChalcogenide

The invention discloses a method for preparing longitudinal heterojunctions of single-layer transition metal chalcogenides by no-glue transfer. Firstly, fused salt is mixed with transition metal oxide powder as an evaporation source; and transition metal chalcogenides are prepared through growth of the fused salt assisted by a chemical vapor deposition method. Then, de-ionized water is used, and is contacted with the transition metal chalcogenides; the transition metal chalcogenides can float along with water; through flowing of the water, the transition metal chalcogenides are transferred to any target substrate; and the longitudinal heterojunctions and multiple layers of stacked longitudinal heterojunctions are prepared through multiple times of transfer of the transition metal chalcogenides. Any organic glue is not used as a middle auxiliary layer, so that the problem of glue remaining can be solved; and any corrosive solution cannot be used, so that the destruction and the doping of the corrosive solution to the transition metal chalcogenides can be prevented, a new method is provided for transfer of the transition metal chalcogenides and preparation of the longitudinal heterojunctions thereof, and the important significance on acceleration of the research and the application of the transition metal chalcogenides and the longitudinal heterojunctions thereof is achieved.

Owner:XI AN JIAOTONG UNIV

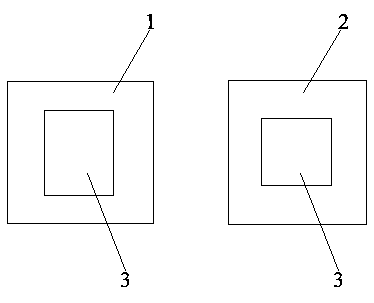

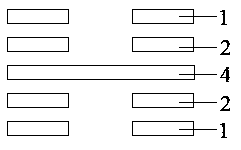

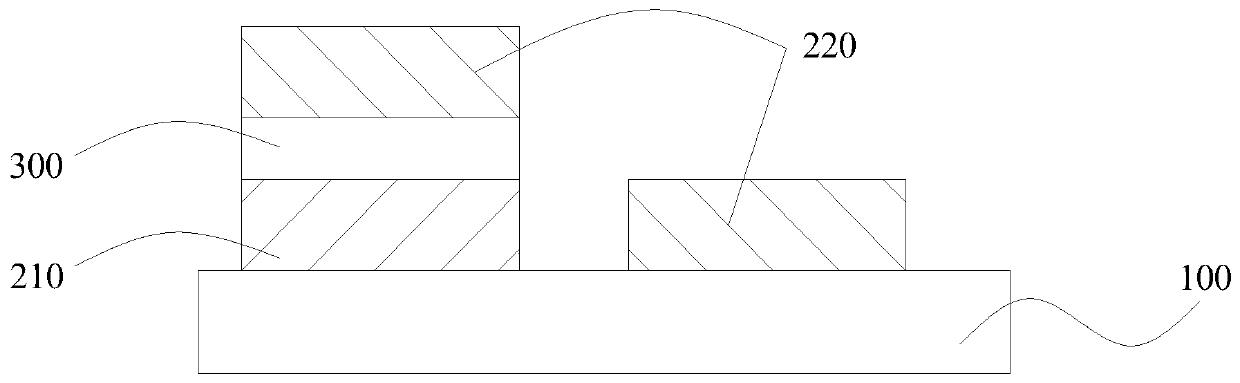

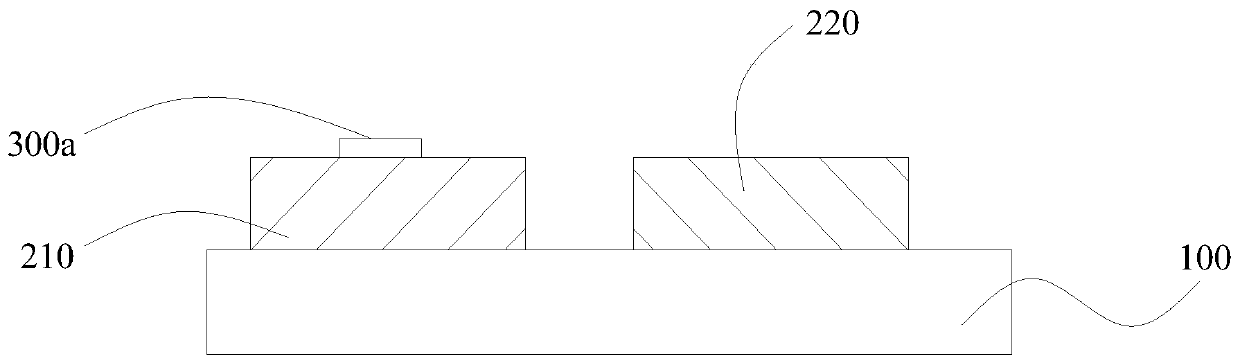

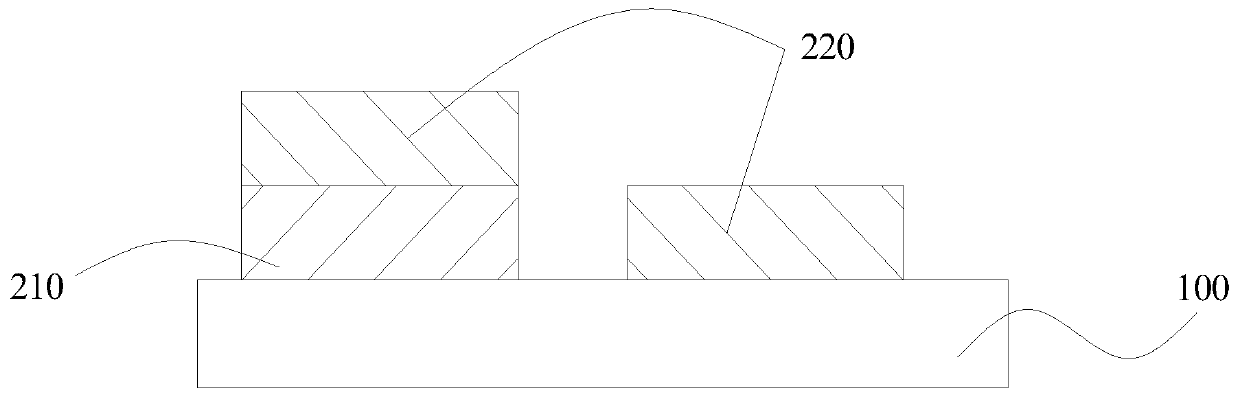

Binary optical filter and manufacture method thereof

The invention discloses a binary optical filter. The binary optical filter includes a substrate, and a plurality of first filtering units and a plurality of second filtering units in array arrangementon two opposite surfaces of the substrate, wherein projections of the first filtering units and the second filtering units on the first surface or the second surface are distributed in a staggered manner. According to the invention, the binary optical filter has different optical filtering functions and can be combined to a mini-size optical detection system so as to apply to fields including medical diagnosis, atmosphere, space, ocean and the like. The invention also discloses a manufacture method of the above binary optical filter. The manufacture method includes selecting the substrate; forming the first filtering units and the second filtering units on two opposite surfaces of the substrate in array arrangement, wherein the projections of the first filtering units and the second filtering units on the first surface or the second surface are distributed in a staggered manner. According to the invention, simple technique and high integration level are achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

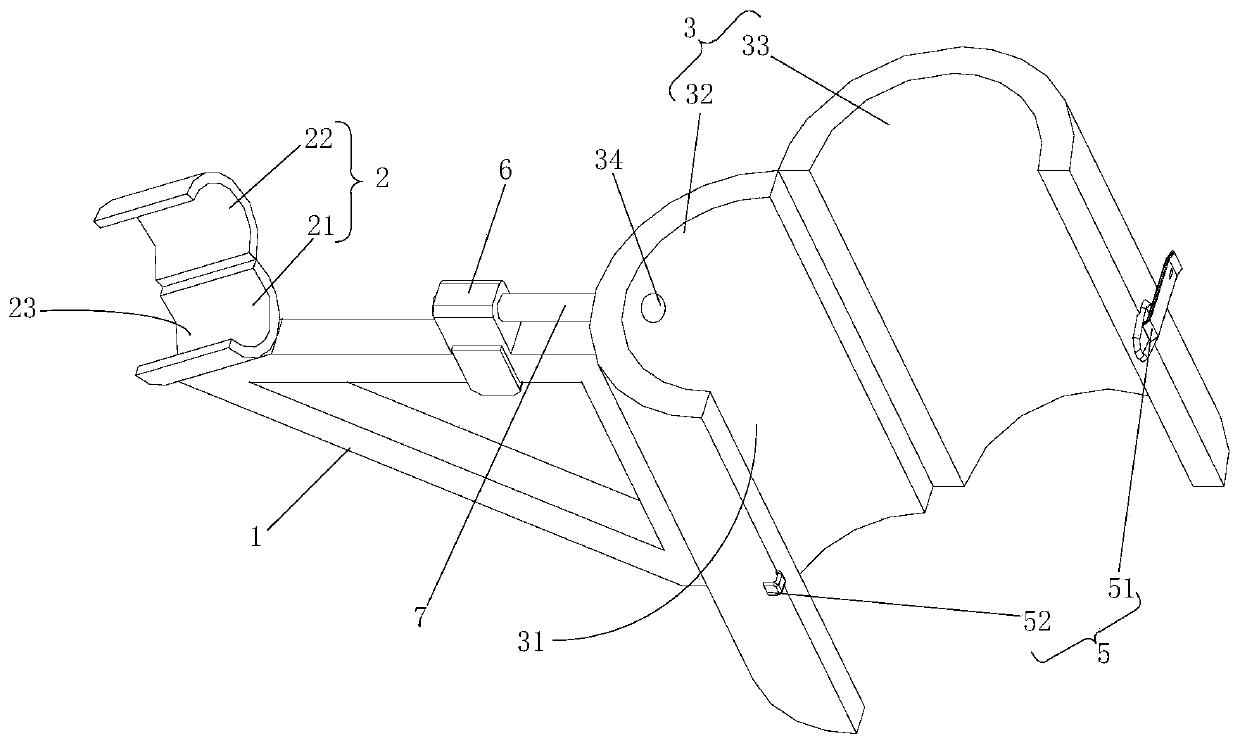

Dispensing and assembling apparatus

InactiveCN104889014ASolve the problem of residual gluePrecise dispensingLiquid surface applicatorsCoatingsBiomedical engineering

Owner:SUZHOU RS TECH

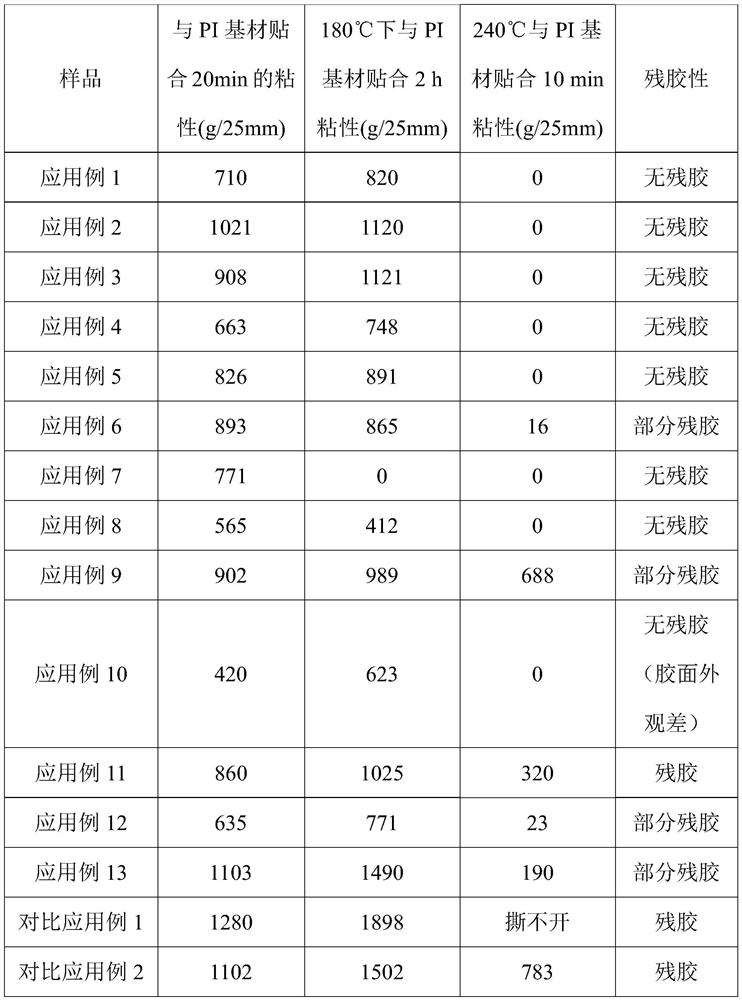

Adhesive and preparation method thereof, and adhesive layer and heat-reducing adhesive tape prepared from adhesive

ActiveCN110938394AImprove high temperature resistanceIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceFunctional monomer

The invention provides an adhesive, a preparation method thereof, an adhesive layer prepared from the adhesive and a heat-reducing adhesive tape. The adhesive is prepared from the following raw materials: a hard monomer, a soft monomer, a functional monomer, a solvent, an initiator, a curing agent and foamed microspheres. According to the adhesive disclosed by the invention, firstly, specific monomers are selected for polymerization, and the high temperature resistance of adhesive layers is effectively improved; secondly, the foaming microspheres are creatively introduced into the preparationraw materials, therefore, after the obtained adhesive layers are compounded with base material layers, heavy release layers and light release layers, the high-temperature-resistant heat-reducing adhesive tape can be obtained, the adhesive layers can be separated from an adhered object through the expansion effect of the microspheres by foaming of the microspheres, and the problem of adhesive residue is fundamentally solved; moreover, at a specific temperature, a stripping process used for debonding the adhesive tape becomes simpler, so that the aims of reducing the processing procedures and improving the production efficiency are fulfilled.

Owner:CYBRID TECHNOLOGIES INC

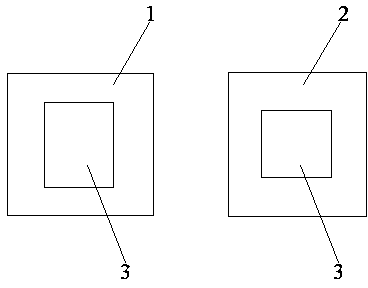

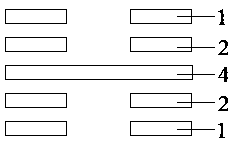

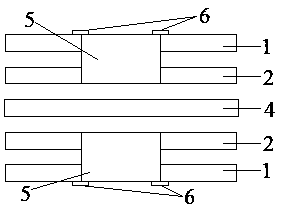

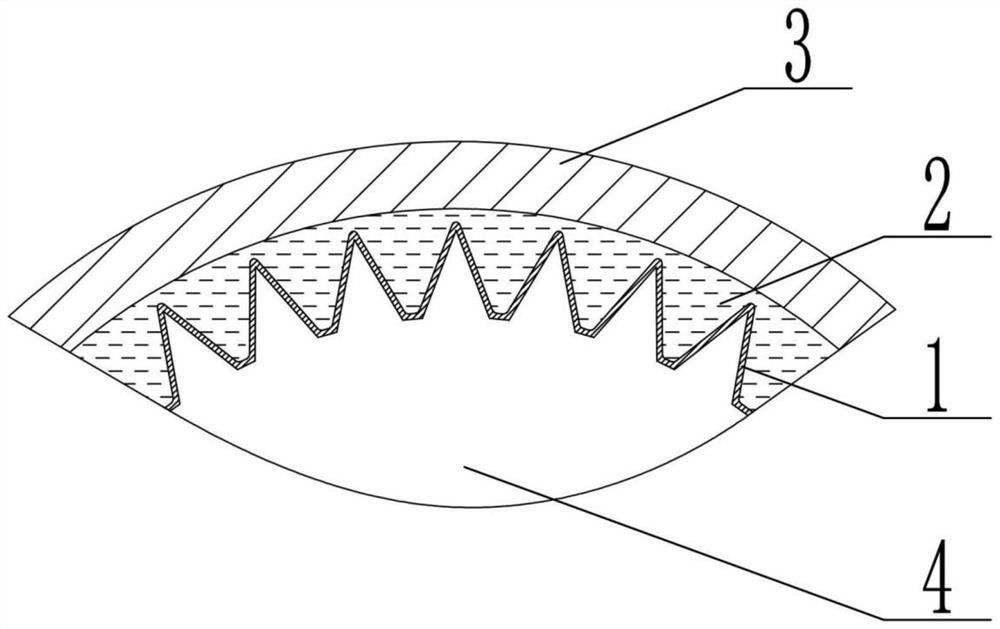

Processing method for slotting process of ridge-flexible combination board

ActiveCN103354704ASimplify the manufacturing processSolve the problem of residual glueMultilayer circuit manufactureEngineeringRidge

The invention relates to the technical field of a manufacturing method of a printed board, particularly to a processing method for a slotting process of a ridge-flexible combination board. The processing method comprises the following steps: S1, carrying out punching slotting processing on a No-flow prepreg, arranging a bridge point at an area correspondingly beyond a flexible region trim line at a sub core plate and carrying out punching slotting on positions, except the bridge point, between the sub core plate and a gasket; S2, successively placing the No-flow prepreg and the sub core plate on a mother core plate and carrying out riveting; S3, placing the riveted ridge-flexible combination board in a laminating machine to carry out hot pressing so as to form a ridge-flexible combination board; and S4, carrying out stitching and then placing the board in a punching machine to punch and break the bridge point with other positions not punched. According to the invention, when punching slotting is carried out at the sub core plate of the ridge-flexible combination board, the gasket and the slot edges are linked and connected by the bridge point; and after the lamination, the punching machine is used to punch and break the bridge point, so that the gasket falls off naturally. Therefore, a problem of adhesive residue of the adhesive tapes at the slot edges can be solved; and a gasket manufacturing process is simplified.

Owner:GCI SCI & TECH

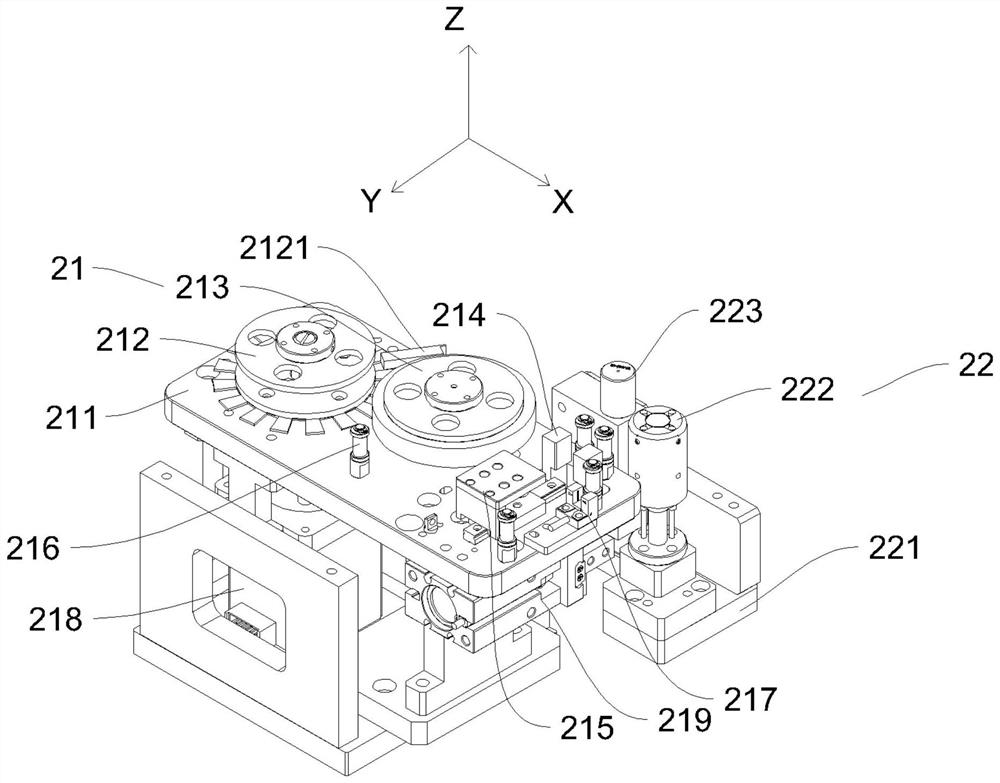

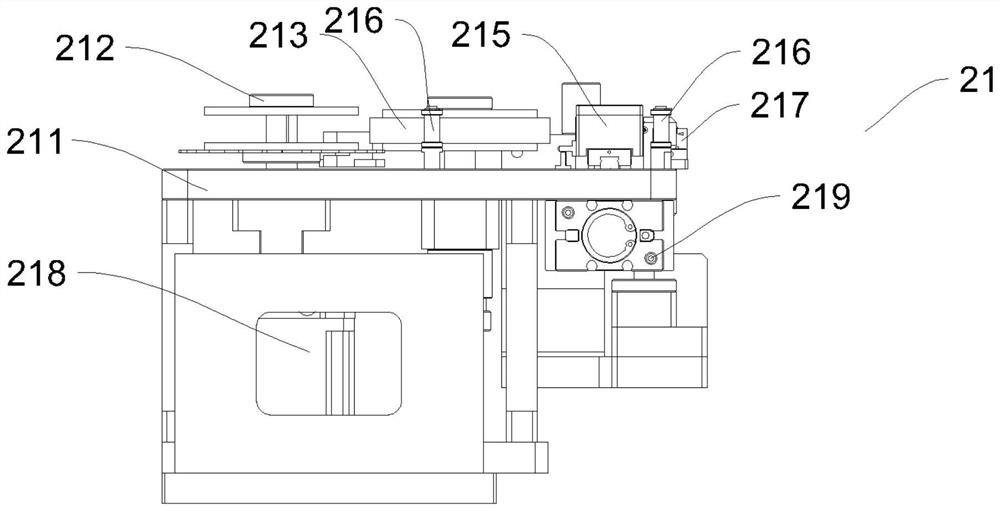

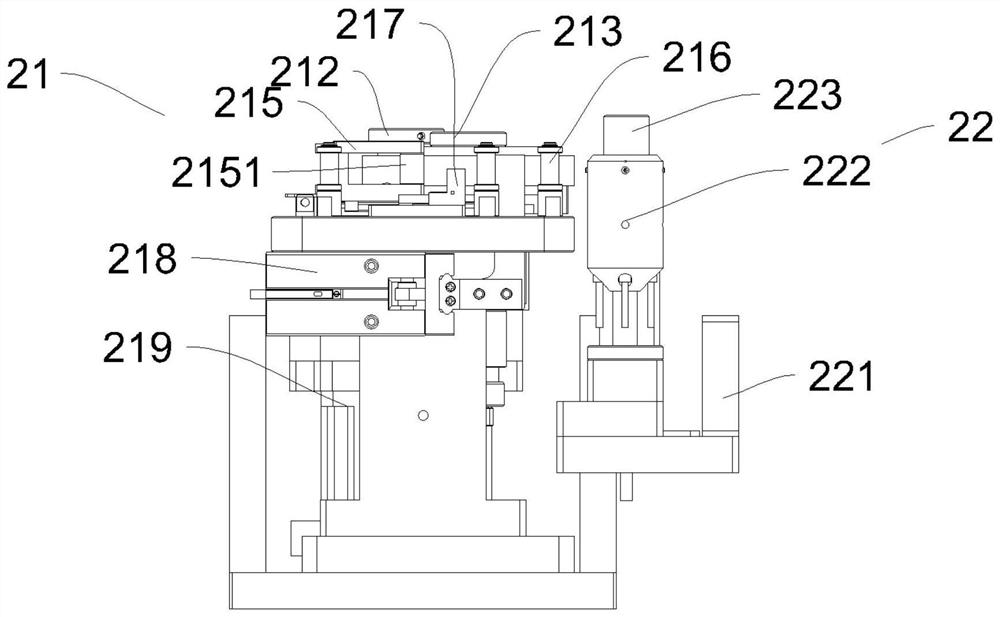

a glue machine

ActiveCN104889028BClose contactSolve the problem of residual glueLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a glue wiping machine, which comprises a material belt, a feeding mechanism, a material receiving mechanism and a base. The belt is in contact with the parts to be wiped, and the material belt is recovered by the described material receiving mechanism after being wiped. The described feeding mechanism and the material receiving mechanism are arranged on the described base. The material mechanism can make the material tape closely contact with the parts to be wiped. At this time, the glue of the parts in contact is wiped clean, so as to solve the problem of residual glue.

Owner:SUZHOU RS TECH

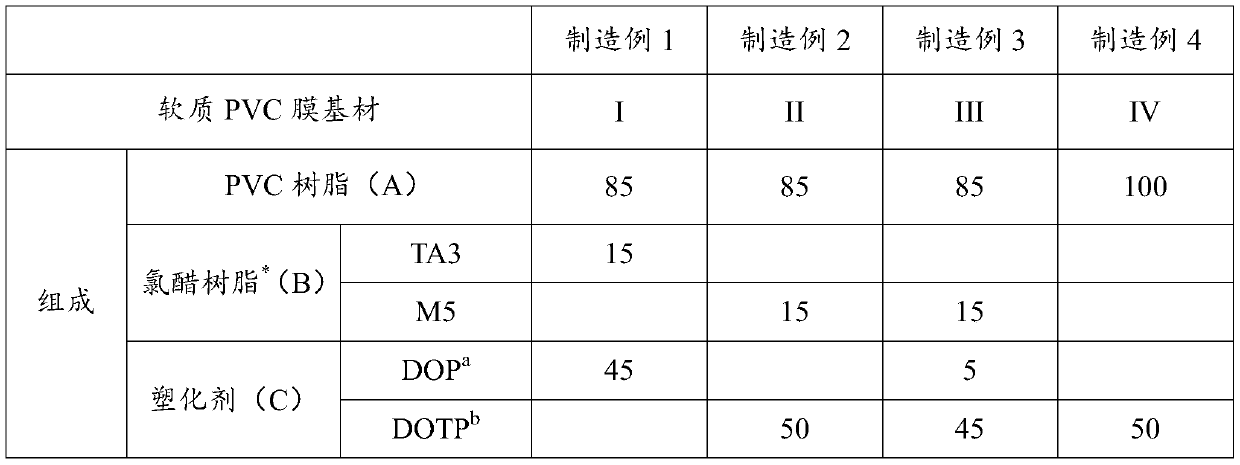

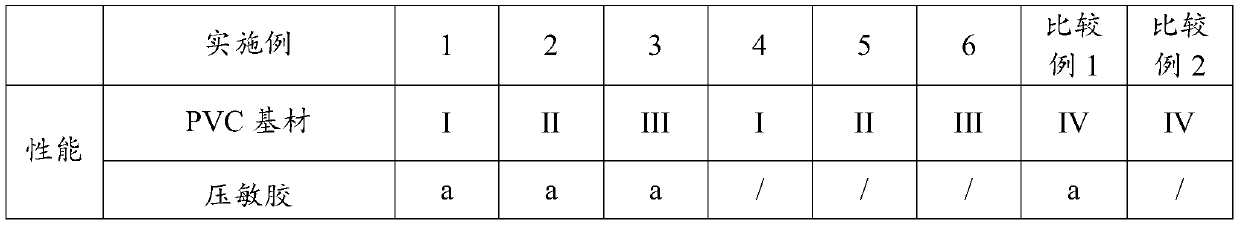

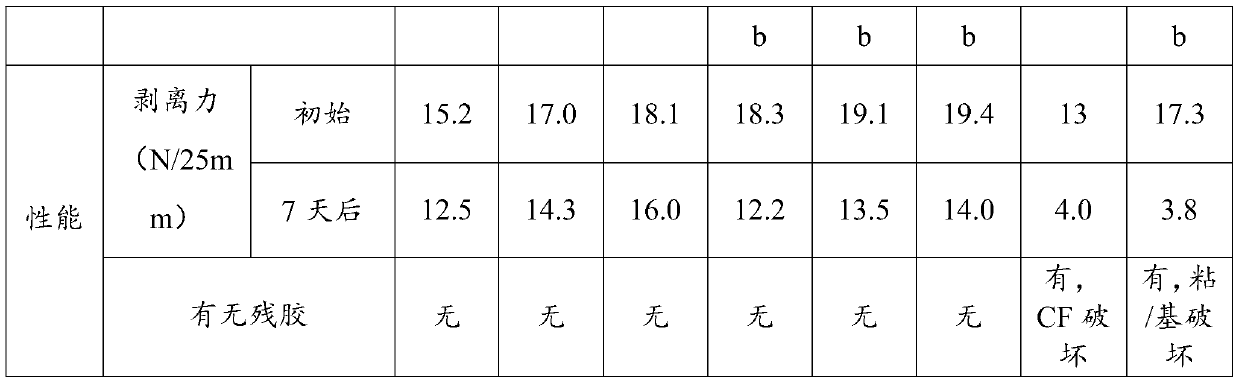

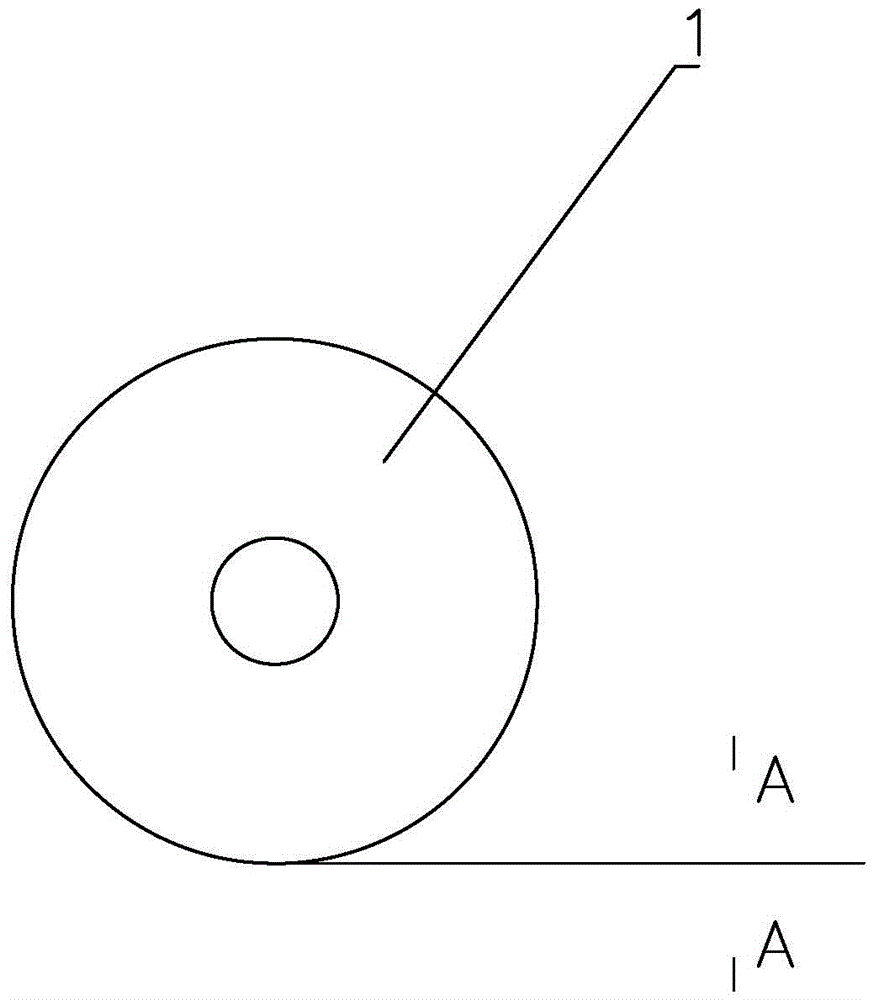

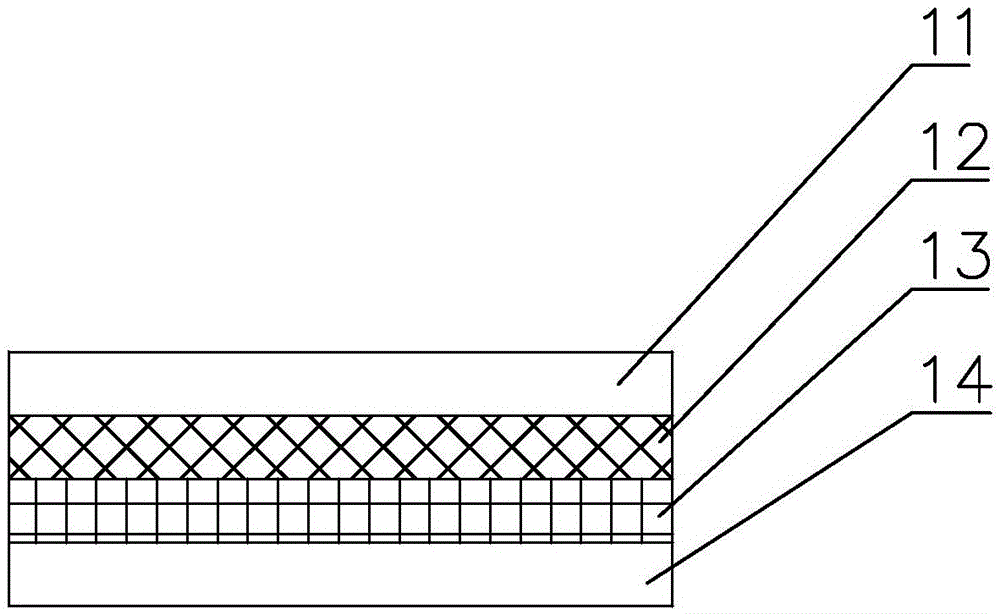

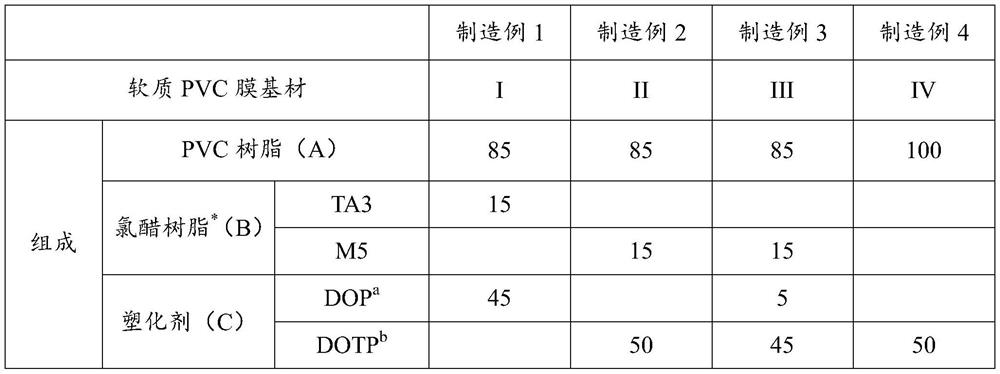

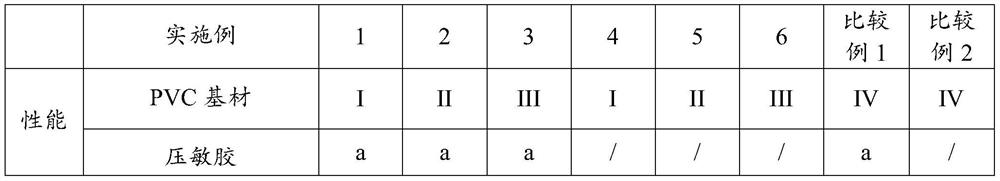

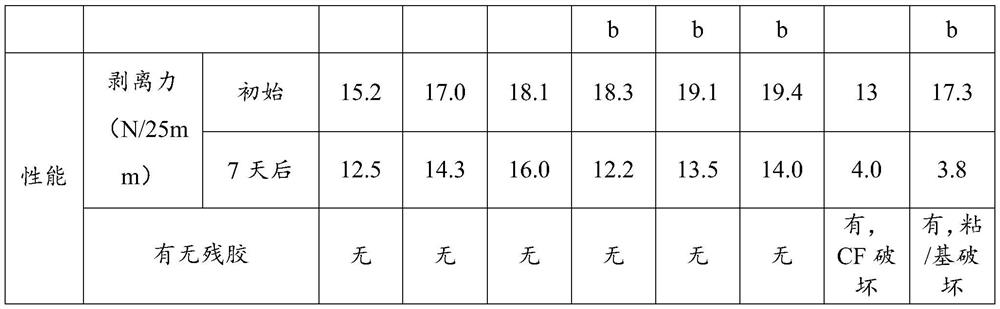

Soft PVC adhesive tape/protective film

ActiveCN111138997AInhibit migrationSolve the bonding problemEster polymer adhesivesPressure sensitive film/foil adhesivesPolymer scienceAdhesive

The invention discloses a soft PVC adhesive tape / protective film. The PVC film comprises a PVC film base material and an acrylic acid pressure-sensitive adhesive coated on the surface of the PVC filmbase material, the composition of the soft PVC film base material is as follows: the soft PVC film base material is prepared from PVC; wherein the weight ratio of the PVC resin to the vinyl chloride-vinyl acetate resin to the plasticizer is (80-90):(10-20):(30-60), the glass transition temperature of the pressure-sensitive adhesive is -30 DEG C to -10 DEG C, the number-average molecular weight is60000-250000, the molecular weight distribution is 2.0-10.0, and the acid value is 5-30 mgKOH / g. According to the soft PVC adhesive tape / protective film, the manufacturing formula of a PVC film basematerial is improved; and meanwhile, the plasticizer-resistant pressure-sensitive adhesive is used, so that under a one-step coating process, a bottom coating process is omitted, the binding force between the plasticizer-resistant pressure-sensitive adhesive and a base material is solved, the damage to a bonding / base interface over time is prevented, the migration of the plasticizer is effectivelyprevented, and the problem of adhesive residue during stripping of a PVC adhesive tape and a PVC protective film is solved.

Owner:张进波

Non-base-material AB adhesive tape

InactiveCN105482732ALow transparencySolve the exhaust differenceFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyurethane adhesiveChemistry

The invention discloses a non-base-material AB adhesive tape which sequentially comprises an upper release layer, an acrylate adhesive layer, a polyurethane adhesive layer and a lower release layer, wherein the acrylate adhesive layer and the polyurethane adhesive layer are directly fitted without a base material, so that the problems of low transparency, poor exhaust performance, high possibility of degumming and unattractiveness are solved. The non-base-material AB adhesive tape is extremely high in transparency, good in exhaust performance, free of degumming, less in defective gum and more beautiful.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

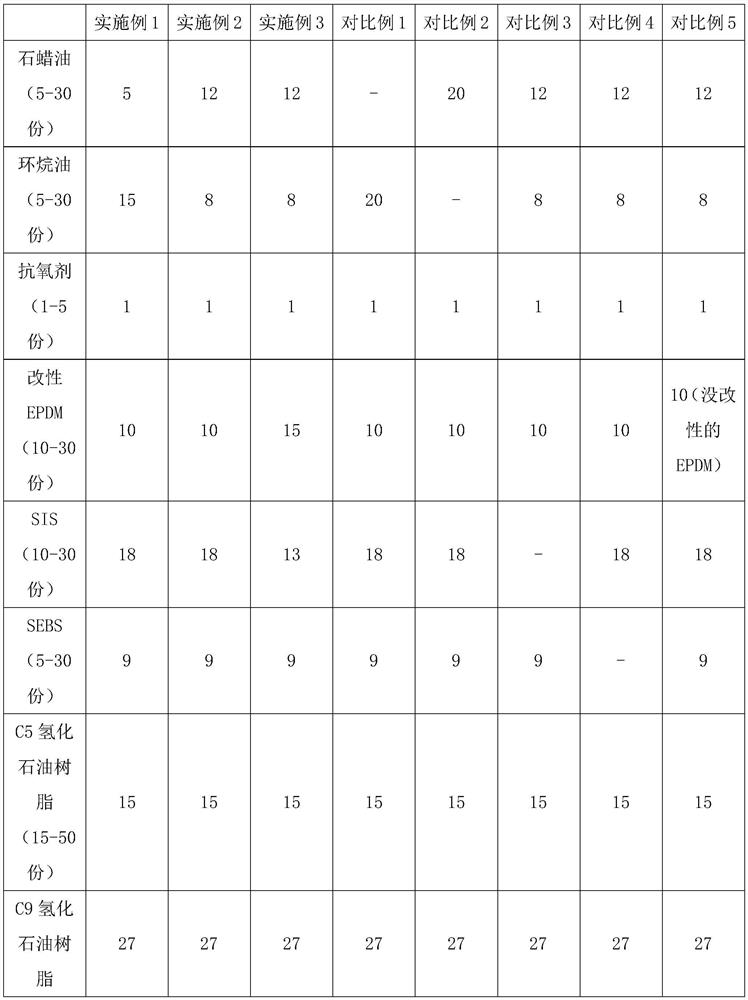

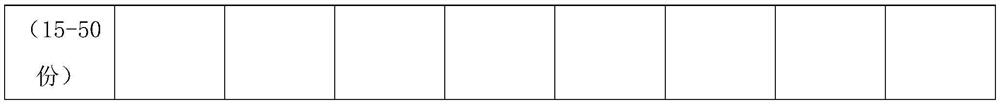

High-temperature movable label hot melt adhesive and preparation method thereof

ActiveCN113249066ASolve bid warpingSolve the problem of residual glueMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention discloses a high-temperature movable label hot melt adhesive and a preparation method thereof. The high-temperature movable label hot melt adhesive is prepared from the following components in parts by weight: 5-30 parts of paraffin oil, 5-30 parts of naphthenic oil, 1-5 parts of an antioxidant, 10-30 parts of modified EPDM, 10-30 parts of SIS, 5-30 parts of SEBS, 15-50 parts of C5 hydrogenated petroleum resin and 15-50 parts of C9 hydrogenated petroleum resin, wherein the modified EPDM is acid anhydride modified EPDM, and the acid anhydride is phthalic anhydride. Through the design of the formula, the thermoplastic elastomers SIS and SEBS and the high-temperature-resistant chemical modified EPDM are blended, and then the naphthenic oil and the paraffin oil are added to act together, so that the problems of mark warping and adhesive residue in a high-temperature environment are solved.

Owner:佛山南宝高盛高新材料有限公司

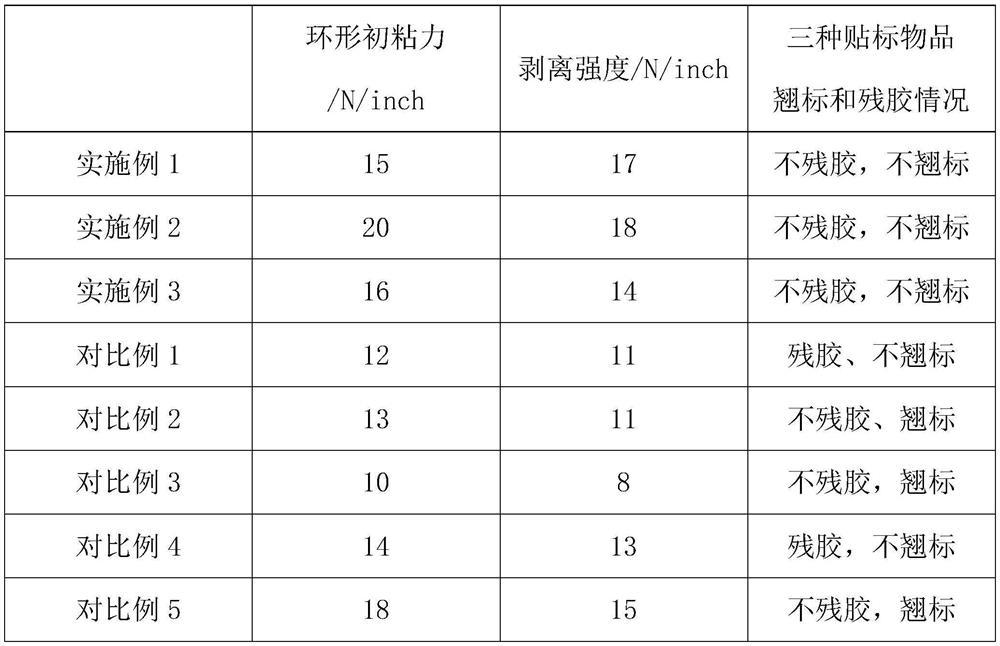

Automatic film tearing mechanism based on products for production

PendingCN114537820AReduces fracture residue problemsSolve the problem of residual glueFinal product manufactureArticle unpackingAdhesive beltStructural engineering

The invention relates to the technical field of film tearing devices, in particular to a product automatic film tearing mechanism based on production, which comprises a fixed mounting base plate, a special-shaped lifting plate, a side end fixing block and a side edge lifting block, the special-shaped lifting plate is arranged on the front side of the fixed mounting base plate through a downward pressing assembly, and the special-shaped lifting plate is in a vertical Z shape. A product is tightly pressed on the surface of a loading table through the lower end of a bottom mounting block, one end of a protective film is tilted through blowing of a high-pressure nozzle, the tilted end of the protective film can be firmly sucked under the negative pressure action of a vacuum negative-pressure suction nozzle, and the tilted end of the protective film can be clamped to the front side surface of a special-shaped lifting plate through the lower end of a strip-shaped protective film clamping plate; and then the product is driven to move in cooperation with the material carrying table, automatic film tearing can be completed, the problem of adhesive residues caused by adhesive tape tearing can be effectively solved, and the problem of protective film breakage residues caused by high-pressure air tearing is greatly solved.

Owner:珠海韦田智科精密机械有限公司

A method for processing through-groove of rigid-flex board

ActiveCN103354704BSimplify the manufacturing processSolve the problem of residual glueMultilayer circuit manufacturePunchingEngineering

The present invention relates to the technical field of manufacturing methods of printed boards, and more particularly, to a method for processing through grooves of rigid-flexible boards. A method for processing a through-groove of a rigid-flexible board, which includes the following steps, S1. For the No-flow prepreg through-groove, a bridge point is set on a sub-core board corresponding to a region other than the outline line of the flexible area, and on the sub-core board Between the spacer and the other positions except the bridge point, open the groove; S2. Place the No-flow prepreg and the sub-core board on the mother core board in sequence, and then perform riveting; S3. Place the riveted rigid-flex board Perform hot pressing in the laminator to form a rigid-flex board; S4. After lamination, place the board in the laminating machine, and break the bridge, and leave the other positions untouched. In the present invention, when the sub-core board of the rigid-flexible board passes through the groove, the gasket is connected with the edge of the groove through the form of bridge points, and the bridge at this position is broken by using a drilling machine after lamination, and the gasket naturally falls off. Solve the problem of adhesive tape residue on the edge of the groove, and simplify the production of gaskets at the same time.

Owner:GCI SCI & TECH

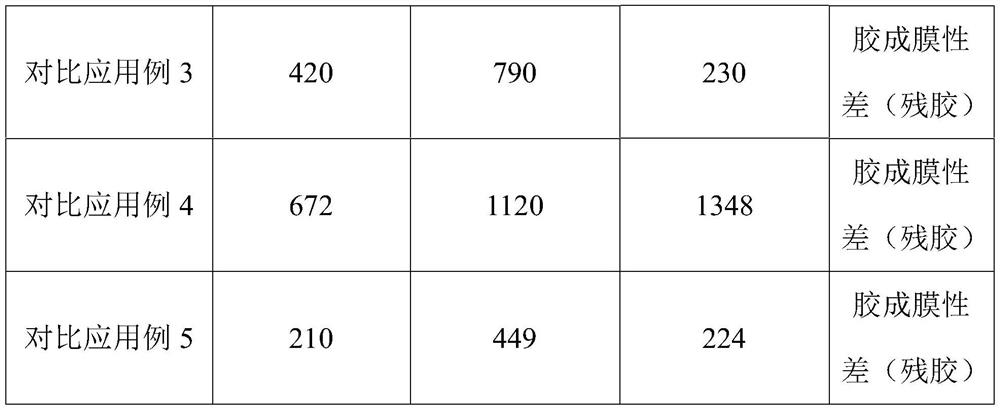

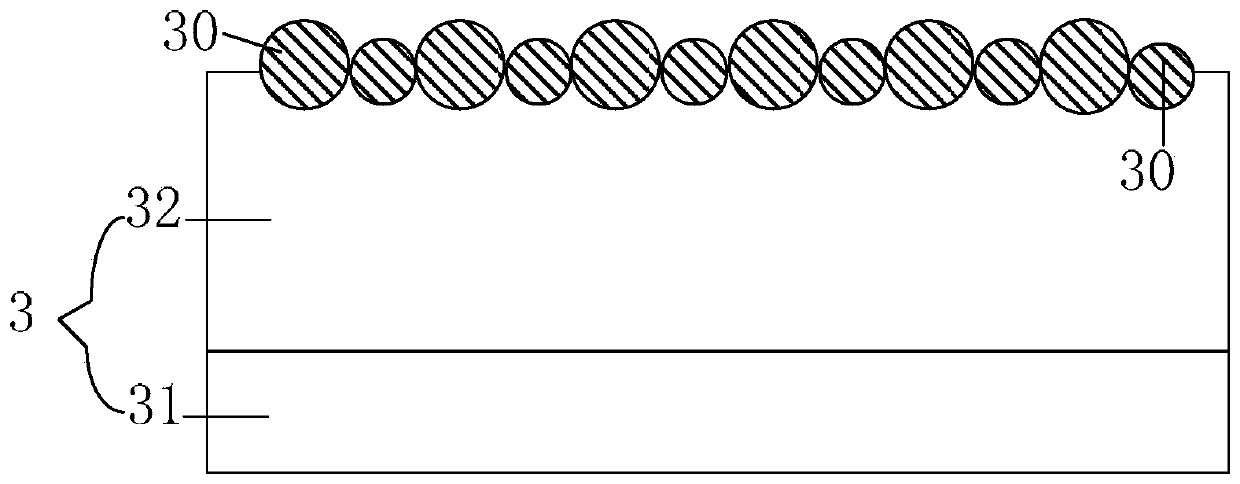

Release film, protective film and display device

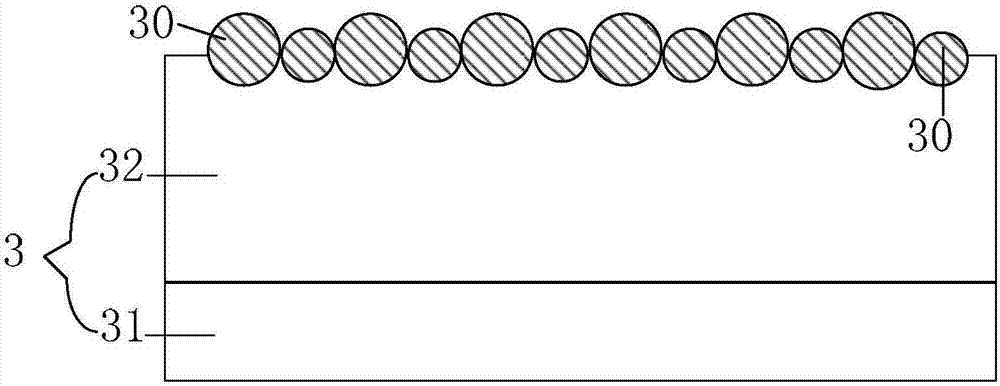

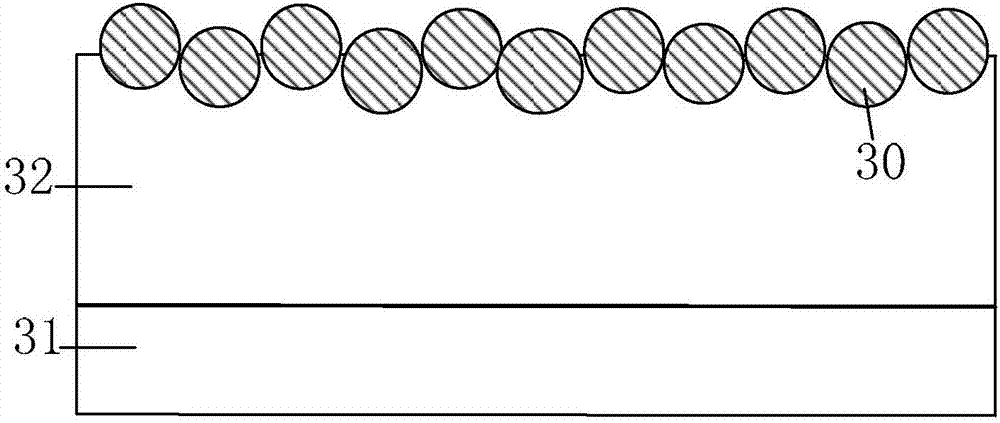

ActiveCN107020775AImprove performanceShorten the ripening timeSynthetic resin layered productsTectorial membraneBiochemical engineering

The invention provides a release film, a protective film and a display device. The release film comprises a release substrate layer and a release layer, wherein the release layer is arranged on the surface of the release substrate layer, one release layer surface far from the release substrate layer is provided with a plurality of extruding particles, which extrude from one surface of the release layer. The surface of the release layer has extruding particles, and when the release film is applied in the protection film, the extruding particles can cause gaps between the release layer and an adhesive layer, the gaps can be convenient for hot air flow, thus shortening the curing time of the adhesive layer, curing the adhesive layer rapidly, and avoiding the problem of adhesive residue. Also, the performance of the protective film can be more stable.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

A kind of adhesive and preparation method thereof, adhesive layer and heat-releasing adhesive tape prepared therefrom

ActiveCN110938394BImprove high temperature resistanceIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceFunctional monomer

The invention provides an adhesive and a preparation method thereof, an adhesive layer prepared therefrom, and a heat-releasing adhesive tape. The raw materials for the preparation of the adhesive include: hard monomers, soft monomers, functional monomers body, solvent, initiator, curing agent and foamed microspheres. The adhesive of the present invention is polymerized by selecting specific monomers, which effectively improves the high temperature resistance of the adhesive layer, and secondly, creatively introduces foamed microspheres into the raw materials for preparation, so that when the obtained adhesive After the adhesive layer is compounded with the substrate layer, the heavy release layer and the light release layer, a high temperature resistant thermal adhesive tape can be obtained. The high temperature resistant thermal adhesive tape can make the adhesive The adhesive layer and the object to be pasted are separated by the expansion of the microspheres, which fundamentally solves the problem of residual adhesive; and, at a specific temperature, the stripping process used for tape loss becomes simpler, That is to say, the purpose of reducing processing procedures and improving production efficiency is achieved.

Owner:CYBRID TECHNOLOGIES INC

Release film, protective film and display device

ActiveCN107020775BImprove performanceShorten the ripening timeSynthetic resin layered productsPolymer scienceDisplay device

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

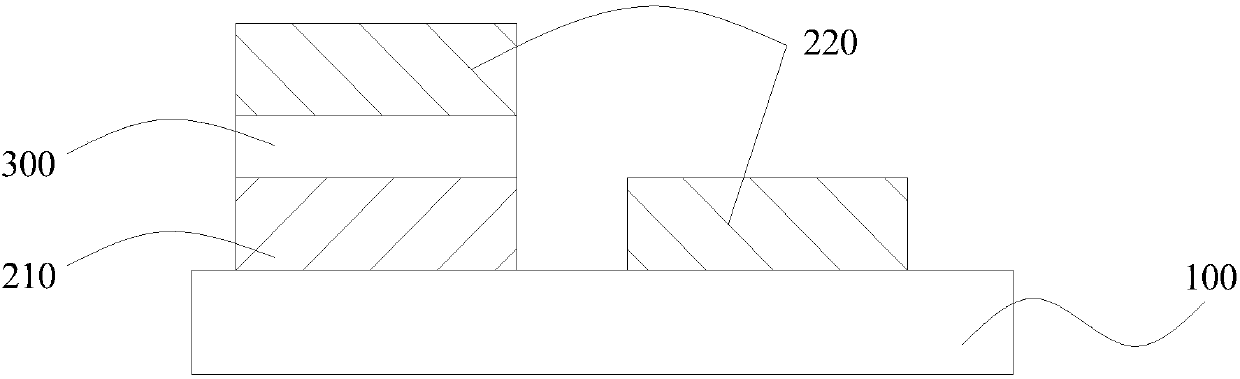

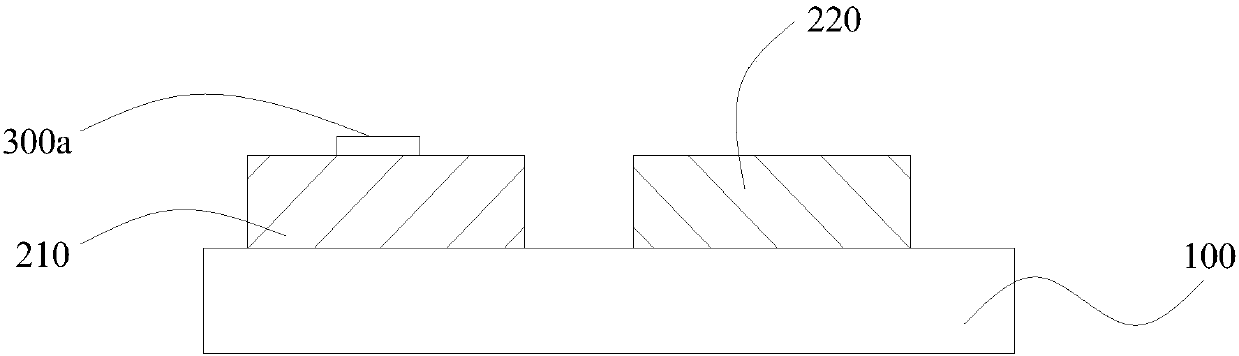

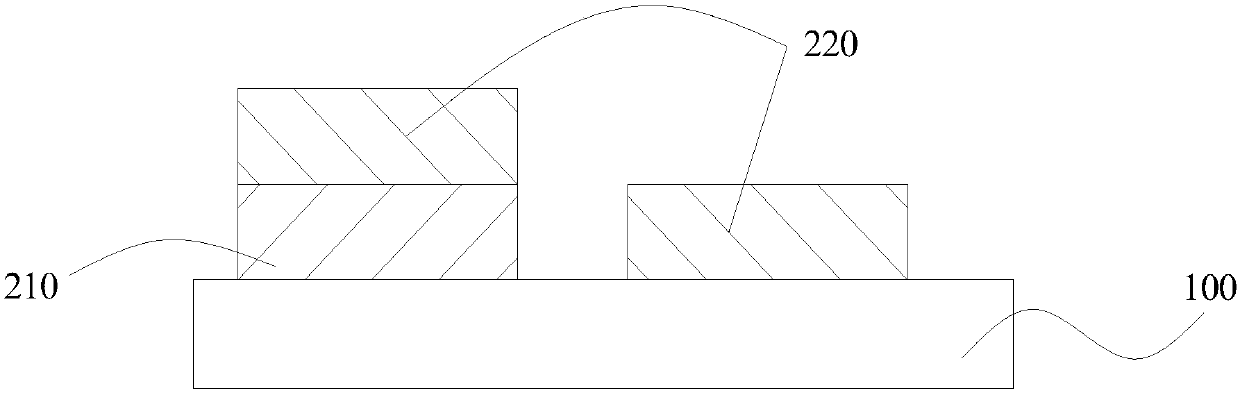

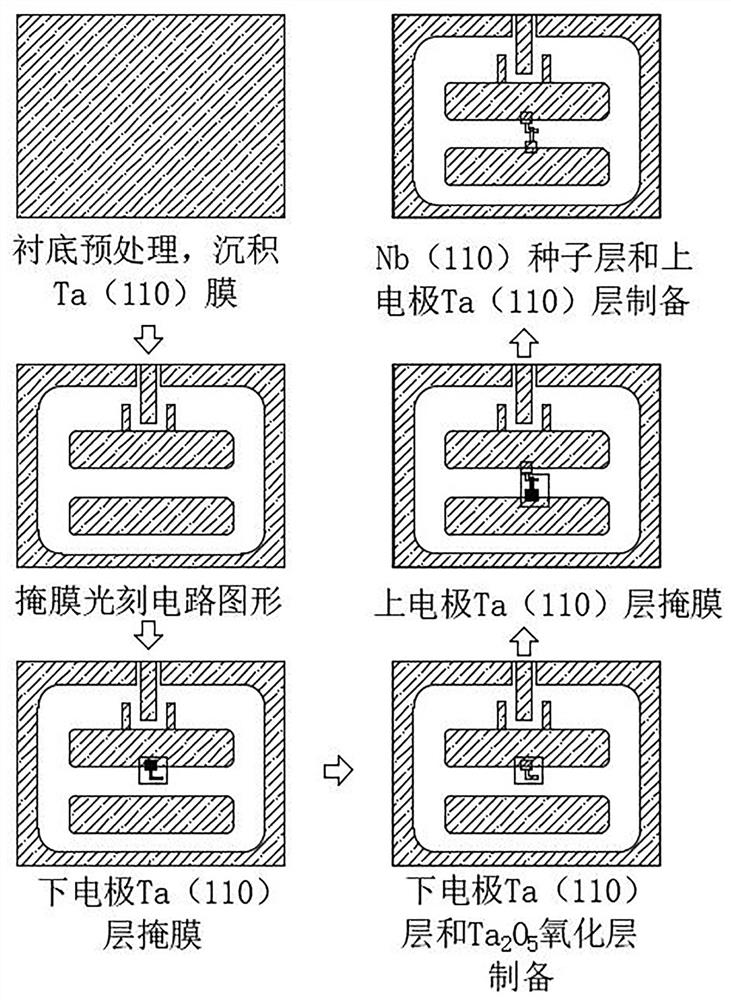

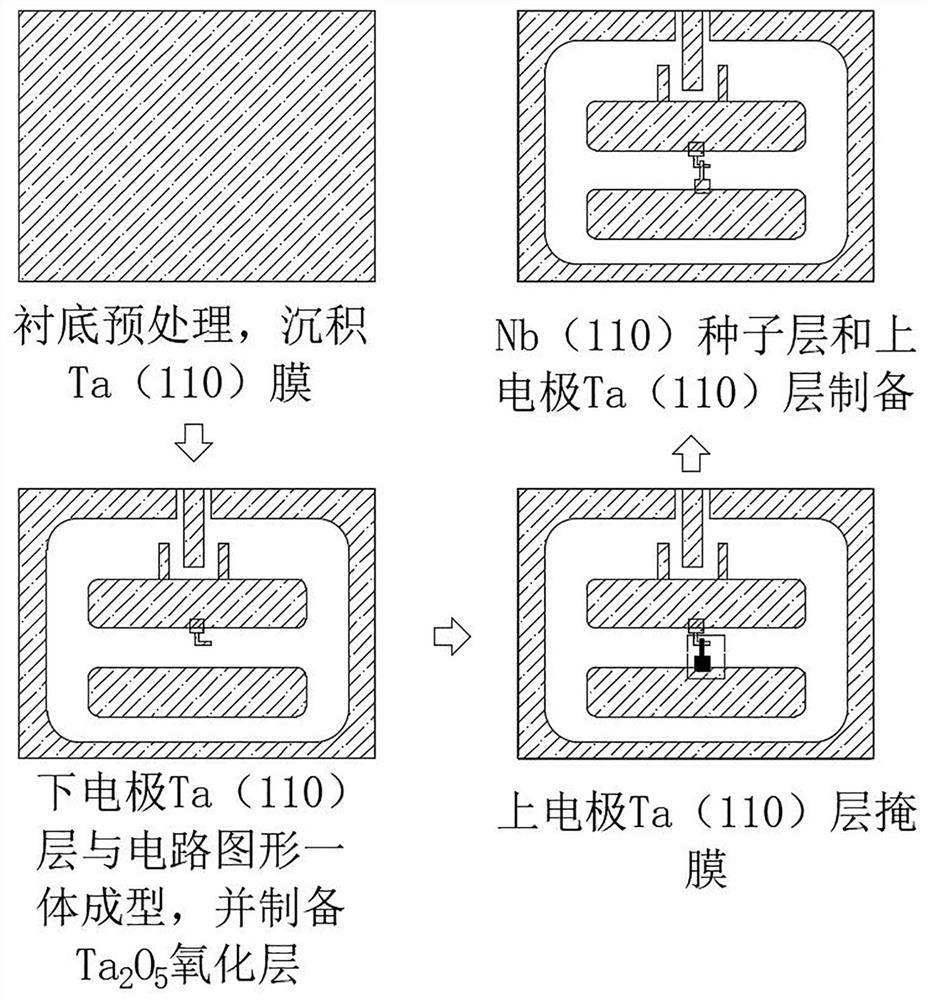

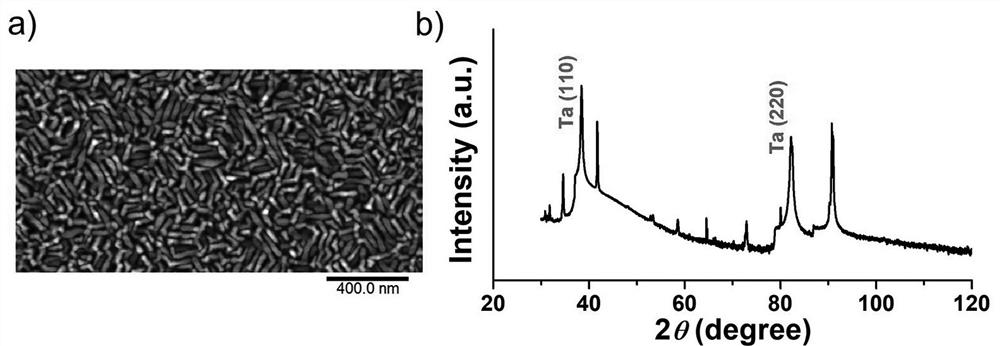

A kind of Josephson junction satisfying large wafer size, preparation method and use

ActiveCN114447204BHighly integratedThe process steps are simpleSuperconductor detailsDissimilar materials junction devicesHemt circuitsThin membrane

The invention provides a Josephson junction satisfying large wafer size, a preparation method and use. ) layer, Ta(110) layer of the lower electrode is prepared on the surface of Ta 2 O 5 The oxide layer is used as an intermediate layer, and the upper electrode Ta (110) layer is formed by mask photolithography, and the Josephson junction is prepared. The present invention uses Ta(110) superconducting thin film as the lower electrode and upper electrode of the Josephson junction, and the Ta(110) film on the surface is 2 O 5 The oxide layer has the characteristics of compactness and stability. It can be passivated and optimized with piranha solution to further remove photoresist residues and ensure the stability of the superconducting circuit structure and Josephson junction. The process steps are simple, stable and controllable, and integrated. With the characteristics of high degree, it can prepare uniform and stable Josephson junctions in the large wafer size range, and is suitable for the regulation of Josephson junctions of different areas.

Owner:GUSU LAB OF MATERIALS

Binary filter and manufacturing method thereof

ActiveCN107870383BReduce adverse effectsGuaranteed functionOptical filtersEngineeringMedical diagnosis

The invention discloses a binary filter, which includes a substrate, and a plurality of first filter units and a plurality of second filter units arrayed on two opposite surfaces of the substrate; wherein, the plurality of first The projections of the filter unit and the plurality of second filter units on the first surface or the second surface are in a cross distribution. The binary optical filter according to the present invention has the characteristics of different filtering functions, and can be combined with a micro-optical detection system, so as to be applied in the fields of medical diagnosis, atmosphere, space, ocean and the like. The present invention also discloses a manufacturing method of the above-mentioned binary filter, which includes: selecting a substrate; preparing a plurality of first filter units forming an array distribution and a plurality of second filter units forming an array distribution on two opposite surfaces of the substrate; Two filter units; wherein, the projections of the multiple first filter units and the multiple second filter units on the first surface or the second surface are mutually intersecting. According to the manufacturing method of the present invention, the process is simple and the integration degree is high.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A soft pvc tape/protective film

ActiveCN111138997BInhibit migrationSolve the bonding problemEster polymer adhesivesPressure sensitive film/foil adhesivesPolymer sciencePlasticizer

Owner:张进波

Pressure-sensitive adhesive and preparation method thereof, aluminum coated tape and use thereof

ActiveCN109096958AIncrease stickinessSolve the real problemEster polymer adhesivesPressure sensitive film/foil adhesivesVitrificationFunctional monomer

The invention belongs to the technical field of polymer materials and particularly relates to a pressure sensitive adhesive and a preparation method thereof, an aluminum coated tape and use thereof. The pressure sensitive adhesive is mainly prepared from, by mass parts, 25-75 parts of soft monomer, 5-30 parts of hard monomer, 3-10 parts of functional monomer, and 0.05-0.8 part of initiator and 40-65 parts of solvent. The method for preparing the pressure sensitive adhesive is simple and practical, and a product at a high glass transition temperature and a product at a low glass transition temperature are connected together to form a substance, which achieves molecular level dispersion and a good dispersion effect. The pressure sensitive adhesive is uniform, and the aluminum coated tape ismanufactured and adheres to a smooth steel plate. During the stripping after 60 days, still no adhesive residue occurs on the surface of a glued material, and the adhesive residue-free performance isrelatively durable.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Surface micro-crosslinking process suitable for preparing deep-texture film

InactiveCN113953168AEasy transferThe transfer process went smoothlyPretreated surfacesCoatingsPolymer scienceUV curing

The invention discloses a surface micro-crosslinking process suitable for preparing a deep-texture film. The surface micro-crosslinking process comprises a roller mold with deep textures on the outer surface, the depth of the deep textures on the roller mold is 10-20 microns, the distance between every two adjacent deep textures is 5 microns, and the surface micro-crosslinking process comprises the following steps that A, a UV sol layer is formed on a PET base film; B, a micro-crosslinking surface is formed on the UV sol layer; C, the UV sol layer is pressed together with the roller mold; and D, a UV lamp is adopted for light curing, and rolling is conducted. According to the surface micro-crosslinking process suitable for preparing the deep-texture film, a texture transfer printing process is adopted, namely, a deep texture structure, namely a microstructure, on the surface of the roller mold is transferred to the surface of the PET base film and is firmly combined with the surface of the PET base film, and uniform deep textures are formed; high-precision microstructures can be subjected to transfer printing, and meanwhile, the deep textures with the depth being 10-20 microns also can be subjected to transfer printing; and by means of the manner that micro-crosslinking and UV curing are organically combined, step-by-step effective control of surface micro-crosslinking and overall crosslinking curing of UV resin is realized.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

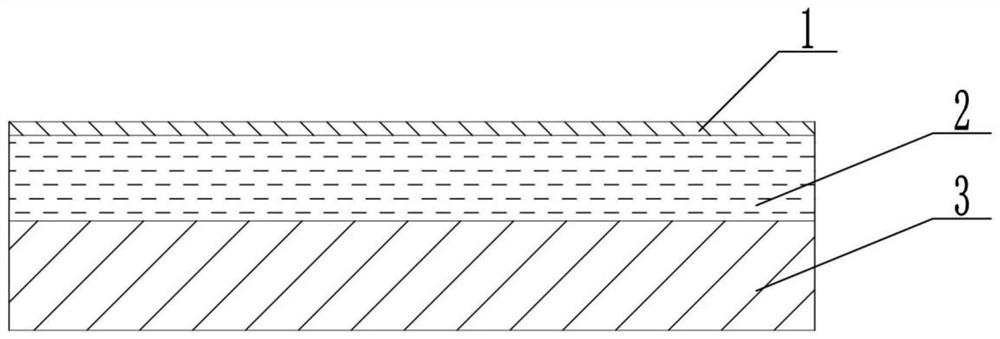

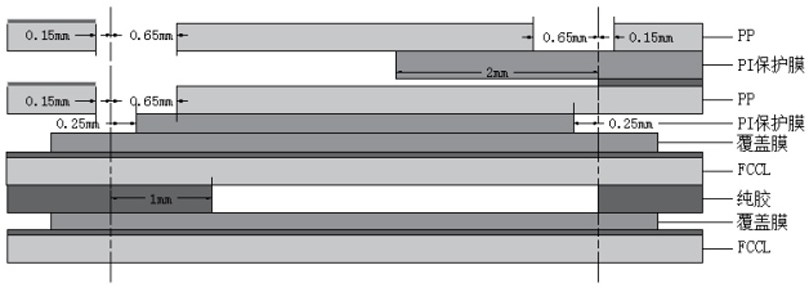

A process method of asymmetric multi-layer rigid-flex board with air cavity

ActiveCN112105175BGuaranteed qualityImprove qualityMultilayer circuit manufactureEngineeringCopper foil

The invention relates to a process method of an asymmetric multilayer rigid-flex board with an air cavity. The process method first prepares double-sided copper-clad laminates, single-sided copper-clad laminates and pure glue, and then prepares the prepared double-sided copper-clad laminates. The upper and lower sides of the multilayer flexible board are stacked with pure rubber and single-sided copper clad laminates in turn to form a multilayer flexible board; then the prepared PP1 and The first copper foil, and a PI protective film is stacked on the outer surface of the first copper foil in the low-level rigid plate area, and the second pressing is performed; then the prepared PP2 is sequentially stacked on the upper and lower sides of the prepared plate. And the second copper foil, carry out the third pressing, after the pressing, carry out CO2 laser controlled deep opening, and after uncovering and forming, perform OSP surface treatment to obtain the finished board. The process method of the asymmetric multi-layer rigid-flex board with air cavity of the present invention has the advantages of good quality, high efficiency and the like.

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

Automatic gate trimming device utilizing in-mold sliding block cutting mechanism in injection mold

The invention relates to the field of cutting-off devices for gates or inner gates, in particular to an automatic gate trimming device utilizing an in-mold sliding block cutting mechanism in an injection mold. The injection mold comprises a mold cavity used for forming a product and a cavity used for forming the gate. The automatic gate trimming device comprises a linear driver and a sliding block which are arranged on the injection mold, wherein the linear driver is fixedly connected with the injection mold, the sliding block is in sliding connection with the injection mold, the sliding block is in transmission connection with an execution part of the linear driver, and a groove which communicates with the interior of the mold cavity and replaces the cavity is formed in the sliding block. According to the automatic gate trimming device utilizing the in-mold sliding block cutting mechanism in the injection mold, the groove in the sliding block is used for replacing the cavity used for forming the gate, the linear driver is used for driving the sliding block to move in the direction away from the mold cavity 2-5 seconds before mold opening, the sliding block can drive the gate to move together so as to be separated from a product, and the problem of how to automatically trim the residual gate in the product after mold opening is solved.

Owner:JIAXING XINYUAN PRECISION MOLD TECH

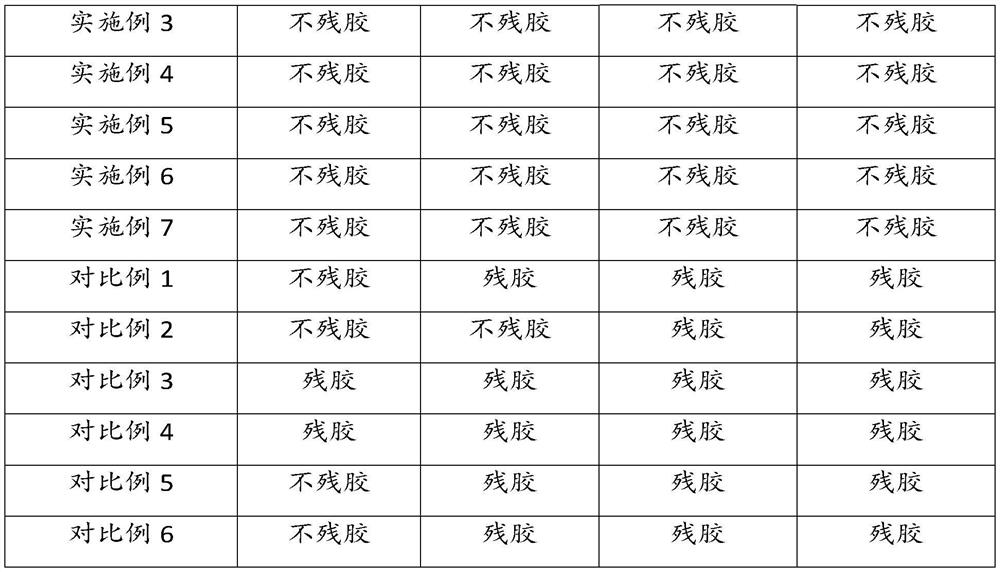

Suction gun fixing support used in oil pipe and casing pipe gas sealing detection

PendingCN111120843ASave human effortReduce testing costsDetection of fluid at leakage pointStands/trestlesEngineeringMechanical engineering

The invention relates to the technical field of sealing detection devices, in particular to a suction gun fixing support used in oil pipe and casing pipe gas sealing detection. The suction gun fixingsupport comprises a support, a suction gun installation part and a fixing part. The support comprises a first end and a second end which are back on to each other. The suction gun installation part comprises a supporting and holding piece arranged at the first end of the support and a buckling piece used for being connected with the supporting and holding piece in a rotating manner. The buckling piece can be buckled together with the supporting and holding part to form a containing space for fixing a suction gun and makes a gun head of the fixed suction gun face the second end of the support.The fixing part comprises a surrounding space capable of being opened and closed and used for surrounding and being fixed to the outer surface of a joint hoop. The fixing part is provided with a through hole used for arranging a pipe body, connected with the gun head of the suction gun, in a penetrating manner. The suction gun can be fixed to joint hoops of oil pipes and casing pipes, needing to be detected, through the suction gun fixing support used in oil pipe and casing pipe gas sealing detection, the process can be completed through one-man operation, and labor is saved.

Owner:通奥检测集团股份有限公司

Pressure-sensitive adhesive and its preparation method, aluminized adhesive tape and its use

ActiveCN109096958BIncrease stickinessSolve the real problemEster polymer adhesivesPressure sensitive film/foil adhesivesPolymer scienceFunctional monomer

The invention belongs to the technical field of polymer materials and particularly relates to a pressure sensitive adhesive and a preparation method thereof, an aluminum coated tape and use thereof. The pressure sensitive adhesive is mainly prepared from, by mass parts, 25-75 parts of soft monomer, 5-30 parts of hard monomer, 3-10 parts of functional monomer, and 0.05-0.8 part of initiator and 40-65 parts of solvent. The method for preparing the pressure sensitive adhesive is simple and practical, and a product at a high glass transition temperature and a product at a low glass transition temperature are connected together to form a substance, which achieves molecular level dispersion and a good dispersion effect. The pressure sensitive adhesive is uniform, and the aluminum coated tape ismanufactured and adheres to a smooth steel plate. During the stripping after 60 days, still no adhesive residue occurs on the surface of a glued material, and the adhesive residue-free performance isrelatively durable.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Glue wiping and needle correcting mechanism

PendingCN111940236AAvoid misalignmentAccurate positioning correctionLiquid surface applicatorsSpraying apparatusAdhesive glueEngineering

The invention discloses a glue wiping and needle correcting mechanism which comprises a glue wiping assembly and a needle correcting assembly located beside the glue wiping assembly; wherein the gluewiping assembly comprises a supporting base, a first roller located above the supporting base, a second roller arranged beside the first roller, and at least one clamping block arranged above the supporting base, and a middle transmission structure including a plurality of transmission rollers, and the clamping blocks are arranged in a face-to-face mode. The glue wiping and needle correcting mechanism has the beneficial effects that, through the glue wiping assembly, a material belt can be in close contact with a needle, and glue on the surface of the needle is wiped up, so that the problem ofresidual glue is solved; a dispensing needle is accurately located and corrected through the needle correcting assembly, so that the phenomenon of dispensing dislocation is avoided.

Owner:SUZHOU RS TECH

Glue-free Transfer Method for Fabricating Monolayer Transition Metal Chalcogenide Longitudinal Heterojunctions

ActiveCN110241400BAvoid destructionAvoid dopingChemical vapor deposition coatingHeterojunctionPhysical chemistry

The invention discloses a method for preparing longitudinal heterojunctions of single-layer transition metal chalcogenides by no-glue transfer. Firstly, fused salt is mixed with transition metal oxide powder as an evaporation source; and transition metal chalcogenides are prepared through growth of the fused salt assisted by a chemical vapor deposition method. Then, de-ionized water is used, and is contacted with the transition metal chalcogenides; the transition metal chalcogenides can float along with water; through flowing of the water, the transition metal chalcogenides are transferred to any target substrate; and the longitudinal heterojunctions and multiple layers of stacked longitudinal heterojunctions are prepared through multiple times of transfer of the transition metal chalcogenides. Any organic glue is not used as a middle auxiliary layer, so that the problem of glue remaining can be solved; and any corrosive solution cannot be used, so that the destruction and the doping of the corrosive solution to the transition metal chalcogenides can be prevented, a new method is provided for transfer of the transition metal chalcogenides and preparation of the longitudinal heterojunctions thereof, and the important significance on acceleration of the research and the application of the transition metal chalcogenides and the longitudinal heterojunctions thereof is achieved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com