Method for transferring graphene based on sublimation method

A graphene, graphene surface technology, applied in the field of graphene, can solve the problems of PMMA can not be completely removed, affect the performance of graphene, limit the application of graphene, etc., to improve the quality and transfer efficiency, short transfer cycle, easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

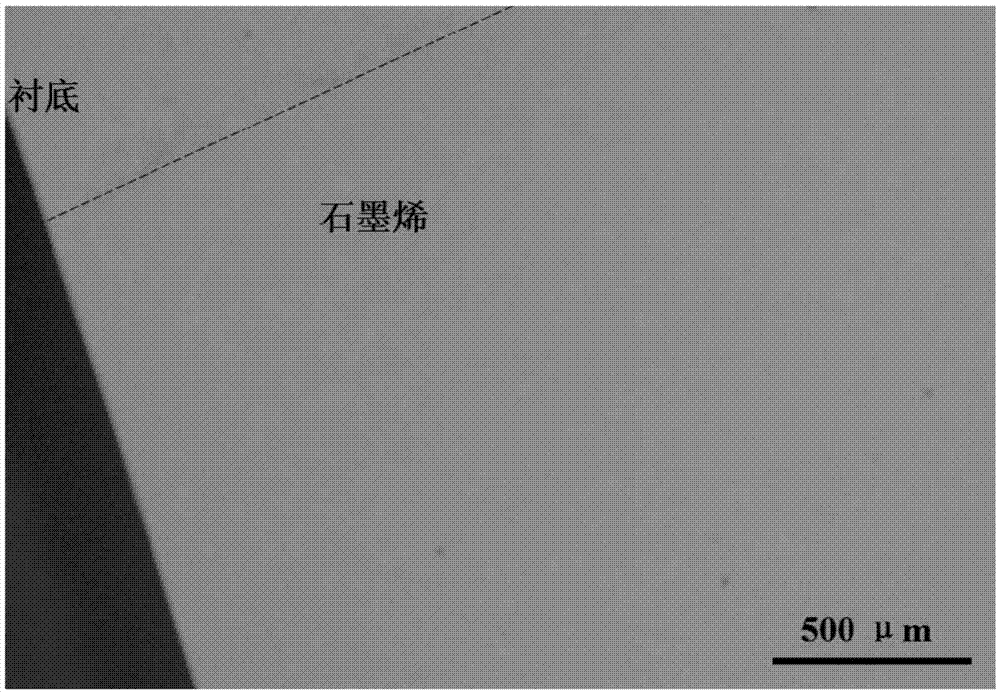

Image

Examples

Embodiment 1

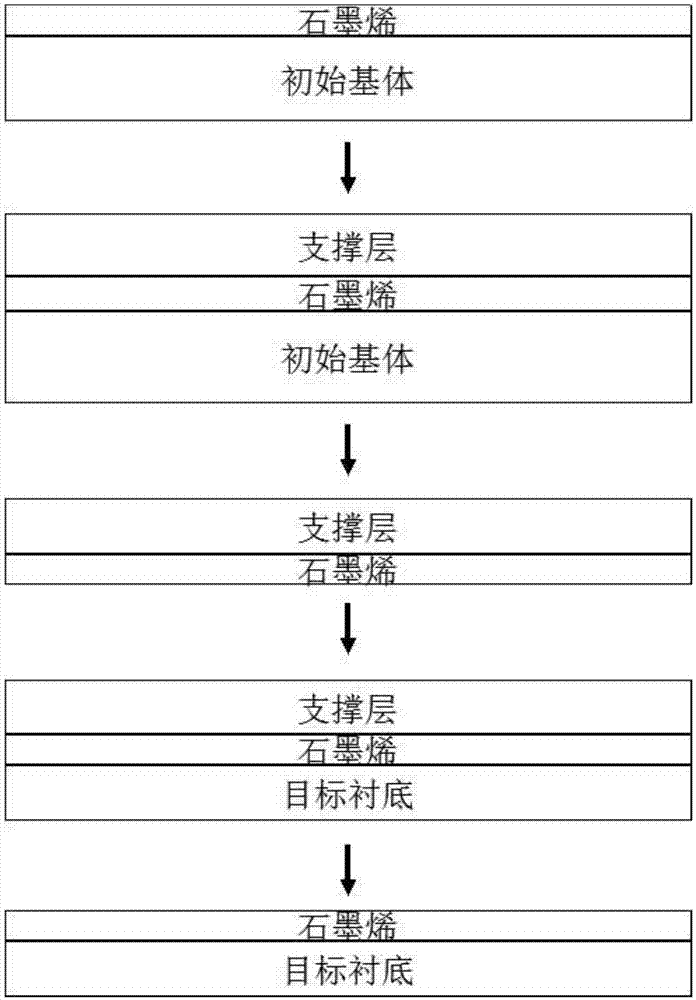

[0027] (1) Formation of support layer: heat naphthalene to 120°C in a beaker, place the copper foil with graphene on top of the beaker and keep it for 20s, naphthalene desublimates on the surface of graphene to form a dense support layer, and the resulting structure is Naphthalene / graphene / copper foil;

[0028] (2) Etching of the initial substrate: configure 1mol / L ferric chloride etching solution, place the naphthalene / graphene / copper foil on the surface of the etching solution, with the naphthalene layer facing up, and wait until the copper foil is completely etched, and then place the Naphthalene / graphene is transferred to deionized water for rinsing, and the resulting structure is naphthalene / graphene;

[0029] (3) Combination of support layer / graphene and target substrate: transfer the rinsed naphthalene / graphene to a silicon wafer (300nm SiO2) covered with 300nm silicon dioxide 2 / Si) substrate, the resulting structure is naphthalene / graphene / 300nm SiO 2 / Si;

[0030]...

Embodiment 2

[0033] The main difference from Example 1 is that the easily sublimable substance is replaced by camphor, and it can also be replaced by other easily sublimable substances.

[0034] (1) Formation of the support layer: heat the camphor to 200°C in a beaker, place the copper foil with graphene on the top of the beaker and keep it for 50s, the camphor will desublimate on the surface of the graphene to form a dense support layer, and the resulting structure is Camphor / graphene / copper foil;

[0035] (2) Etching of the initial substrate: configure 1.5mol / L ferric chloride etching solution, place the camphor / graphene / copper foil on the surface of the etching solution, with the camphor layer facing up, wait until the copper foil is completely etched, and then Camphor / graphene is transferred to deionized water for rinsing, and the resulting structure is camphor / graphene;

[0036] (3) Combination of support layer / graphene with target substrate: transfer the rinsed camphor / graphene to a...

Embodiment 3

[0039] The main difference from Embodiment 1 is that proper heating of the target substrate can speed up the sublimation of the support layer and further shorten the transfer time.

[0040] (1) Formation of support layer: heat naphthalene to 120°C in a beaker, place the copper foil with graphene growing on the top of the beaker and keep it for 30s, naphthalene desublimates on the surface of graphene to form a dense support layer, and the resulting structure is Naphthalene / graphene / copper foil;

[0041] (2) Etching of the initial substrate: configure 2mol / L ferric chloride etching solution, place the naphthalene / graphene / copper foil on the surface of the etching solution, with the naphthalene layer facing up, and wait until the copper foil is completely etched, and then place the Naphthalene / graphene is transferred to deionized water for rinsing, and the resulting structure is naphthalene / graphene;

[0042] (3) Combination of support layer / graphene and target substrate: transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com