Suction gun fixing support used in oil pipe and casing pipe gas sealing detection

A fixed bracket, air-tight technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, machine/support, etc., can solve the problem of broken sniffer gun and detection takes a certain time , sniffer gun fixing and disassembly are cumbersome and other problems, to achieve the effect of saving inspection costs and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

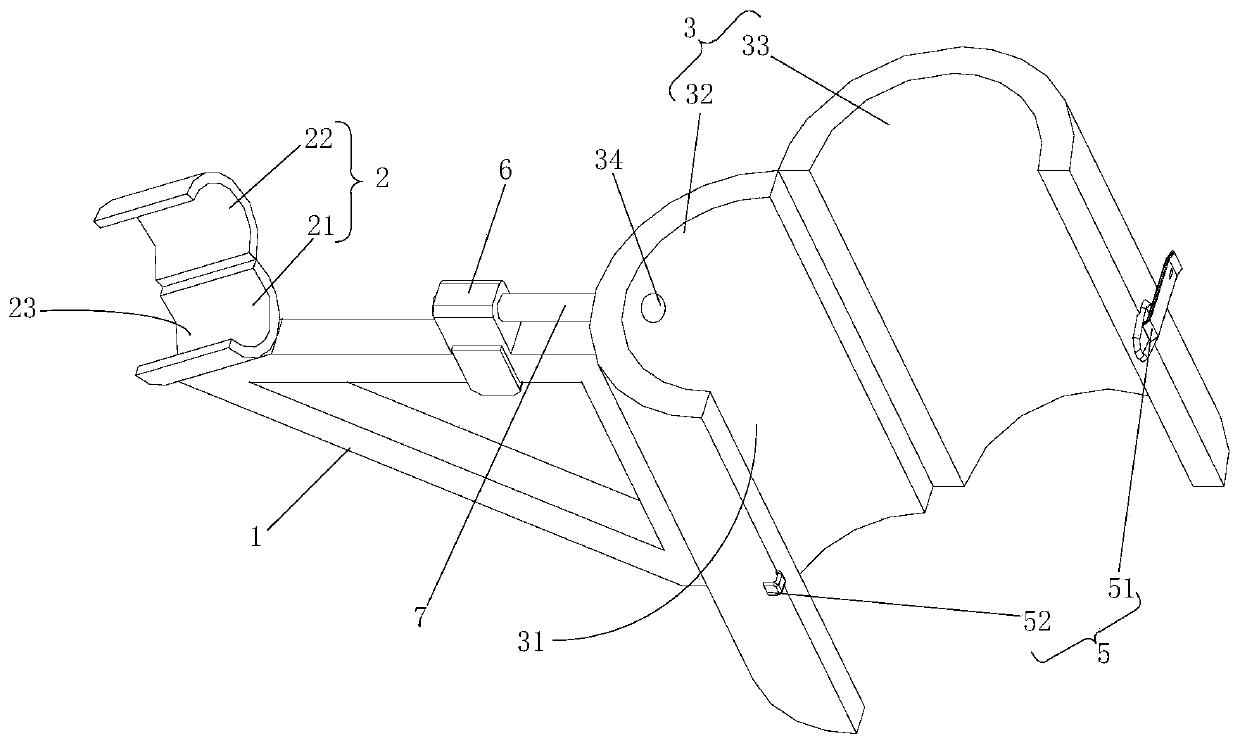

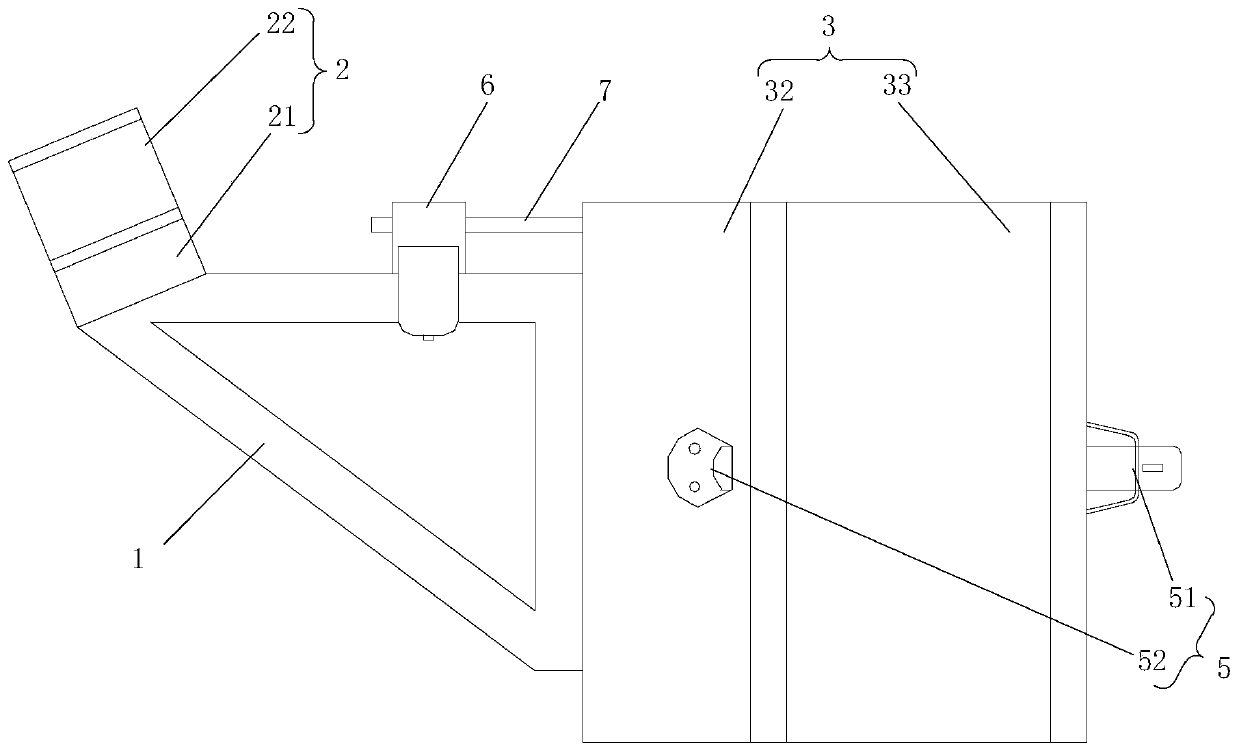

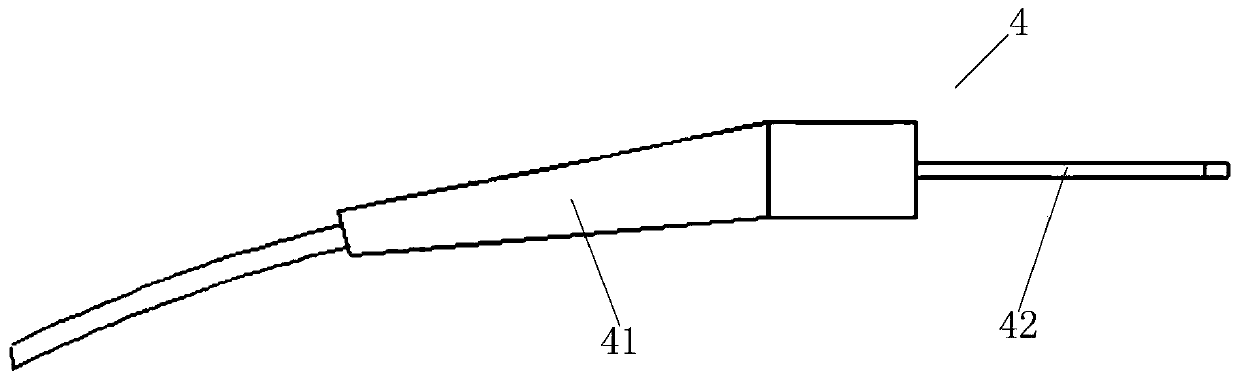

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe the fixed bracket of the suction gun used in the detection of the air seal of the oil casing according to the present invention. Specific embodiments, structures, features and effects thereof are described in detail below. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

[0033] like Figure 1-Figure 3 As shown, an embodiment of the present invention proposes a suction gun fixing bracket used in oil casing gas seal detection, which includes: a bracket 1, a suction gun mounting part 2, and a fixing part 3; the bracket 1 includes a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com