A soft pvc tape/protective film

A protective film, PVC resin technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet adhesives, etc., can solve the problems of complicated manufacturing process and increased cost, and achieve the effect of preventing the migration of plasticizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

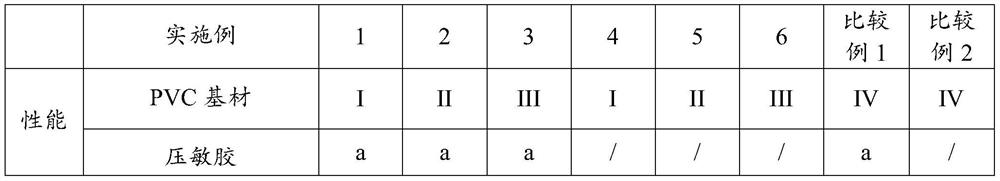

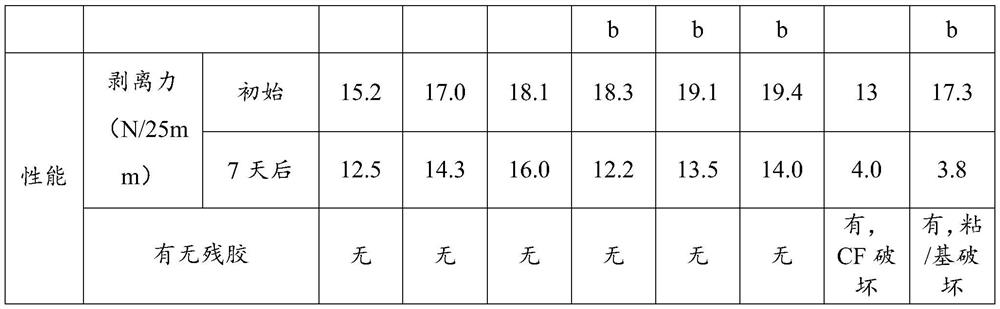

Examples

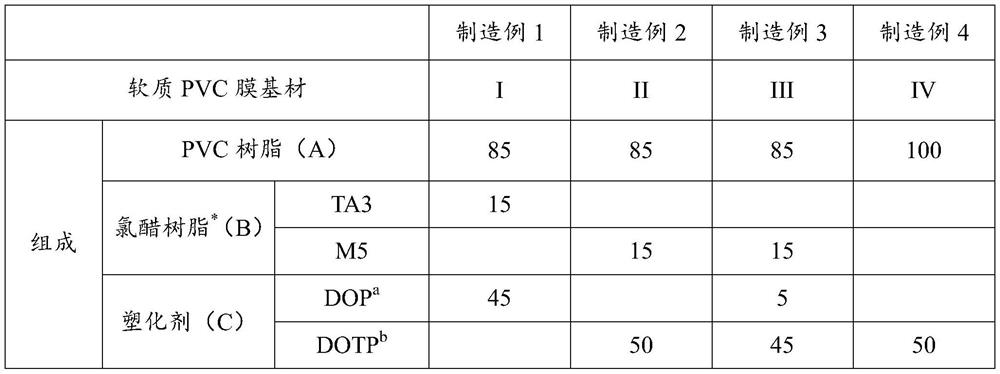

manufacture example 1~4

[0024] According to the proportions in the table below, each component is fully mixed and swollen, and a film material with a thickness of 150 μm is made on a polymer calender.

[0025]

[0026] * Manufactured by Nissin Chemical Industry Co., Ltd.; a Diisooctyl phthalate; b Diisooctyl terephthalate.

Synthetic example 1

[0028] Configure a mixer, a reflux condenser, and a flask with a thermometer, add 41 parts of methyl acrylate, 44 parts of isooctyl acrylate, 13.5 parts of methyl methacrylate, 1.5 parts of acrylic acid, and 0.5 parts of initiator azoisobisbutyronitrile (AIBN). Parts, 70 parts of ethyl acetate, after mixing evenly, control the external temperature, keep the reflux state, and obtain the pressure-sensitive adhesive solution after 6 hours. After the reaction was completed, 50 parts of butyl acetate was added for dilution and stirring, and after further cooling to room temperature, 0.2 parts of the required curing agent aluminum acetylacetonate (dissolved in 30 parts of isopropanol) was added to obtain adhesive solution a. Theoretical glass transition temperature Tg~-20°C, theoretical acid value 12.7mgKOH / g, GPC test results: Mn=88600, Mw=621000, Mw / Mn=7.01.

Synthetic example 2

[0030]Configure a mixer, a reflux condenser, and a flask with a thermometer, add 38 parts of methyl acrylate, 46 parts of isooctyl acrylate, 13.5 parts of methyl methacrylate, 2.5 parts of acrylic acid, and 0.3 parts of initiator azoisobisbutyronitrile (AIBN) Parts, 70 parts of ethyl acetate, after mixing evenly, control the external temperature, keep the reflux state, and obtain the pressure-sensitive adhesive solution after 6 hours. After the reaction was completed, 50 parts of butyl acetate was added for dilution and stirring, and after further cooling to room temperature, 0.4 parts of the required curing agent aluminum acetylacetonate (dissolved in 30 parts of isopropanol) was added to obtain adhesive solution b. Theoretical glass transition temperature Tg~-25°C, theoretical acid value 18.0mgKOH / g, GPC test results: Mn=197000, Mw=690000, Mw / Mn=3.50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com