High-temperature movable label hot melt adhesive and preparation method thereof

A technology of hot melt adhesive and production method, which is applied in the direction of adhesives, heat-activated films/sheets, polymer adhesive additives, etc., can solve problems such as warped labels and residual glue, achieve good adhesion, simple preparation method, Effects suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned high-temperature removable label hot-melt adhesive comprises the following steps:

[0048] (1) Add paraffin oil, naphthenic oil, antioxidant in stainless steel reactor, heat up to 140 ℃;

[0049] (2) Then add modified EPDM and SEBS, add SIS after 30 minutes, and keep stirring until the whole system is completely melted;

[0050] (3) After the whole system is completely melted, add C5 hydrogenated petroleum resin and C9 hydrogenated petroleum resin, stir evenly, vacuumize for 20 minutes, and discharge the material. After cooling, you can get a high-temperature removable label hot melt adhesive.

Embodiment 1-3 and comparative example 1-5

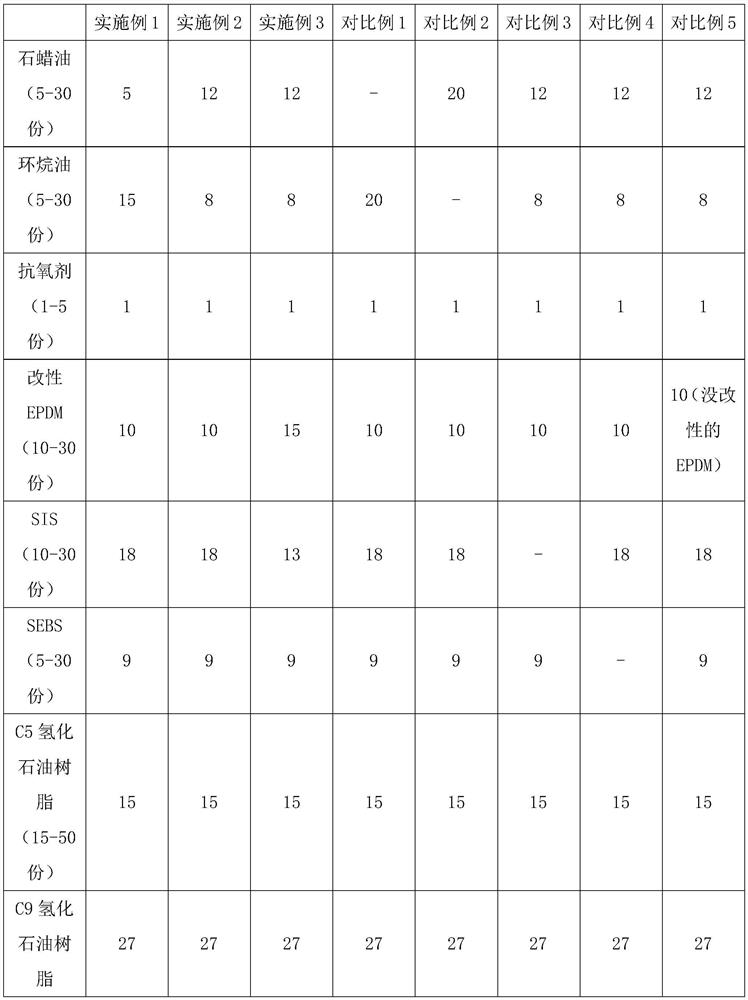

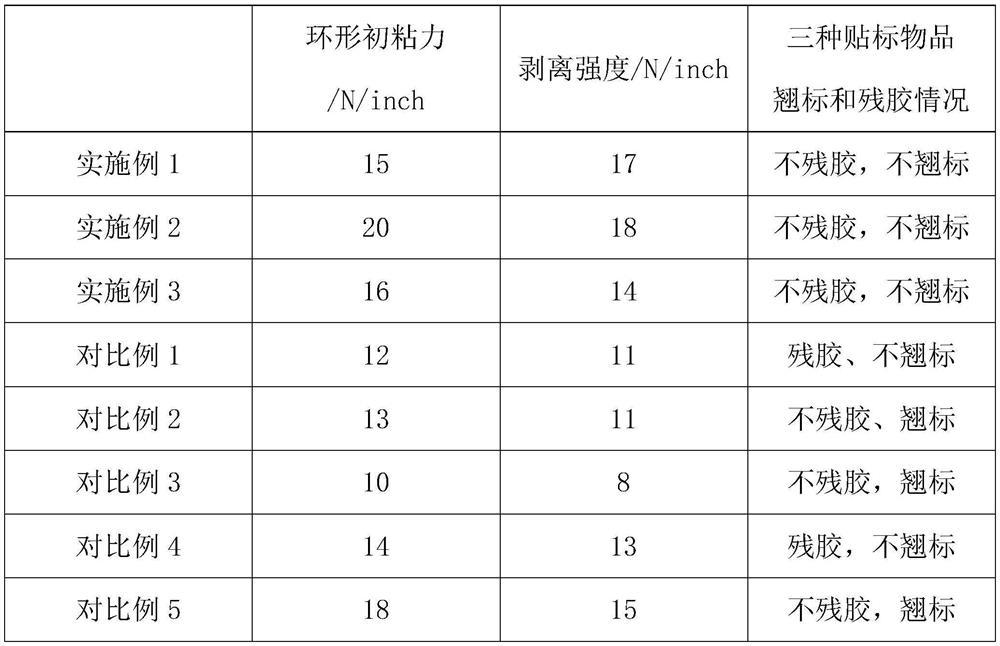

[0053] Weigh the raw materials according to the proportions in Table 1, respectively, and make hot melt adhesives according to the preparation methods after Table 1, correspondingly to obtain hot melt adhesives in different embodiments, see Table 1 for details:

[0054] Table 1 embodiment 1-3 and comparative example 1-5 raw material ratio table

[0055]

[0056]

[0057] Wherein, if there is no special instruction in Table 1, in order to reflect the comparability of test effect, the raw material that adopts is consistent, as paraffin oil is 100# paraffin base oil; SIS was purchased from Shandong Jusheng Technology Co., Ltd. SIS with brand number 1220; SEBS was purchased from SEBS rubber with brand number 1652 from Kraton Company of the United States; C5 hydrogenated petroleum resin was purchased from C5 hydrogenated petroleum resin produced by Eastman Company of the United States; C9 hydrogenated petroleum The resin was purchased from C9 hydrogenated petroleum resin prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com