Frictioning machine

A technology of glue rubbing machine and material receiving mechanism, which is applied in the direction of coating and liquid coating device on the surface, etc., which can solve the problems of unable to discharge glue, poor control of glue amount, unprepared glue dispensing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

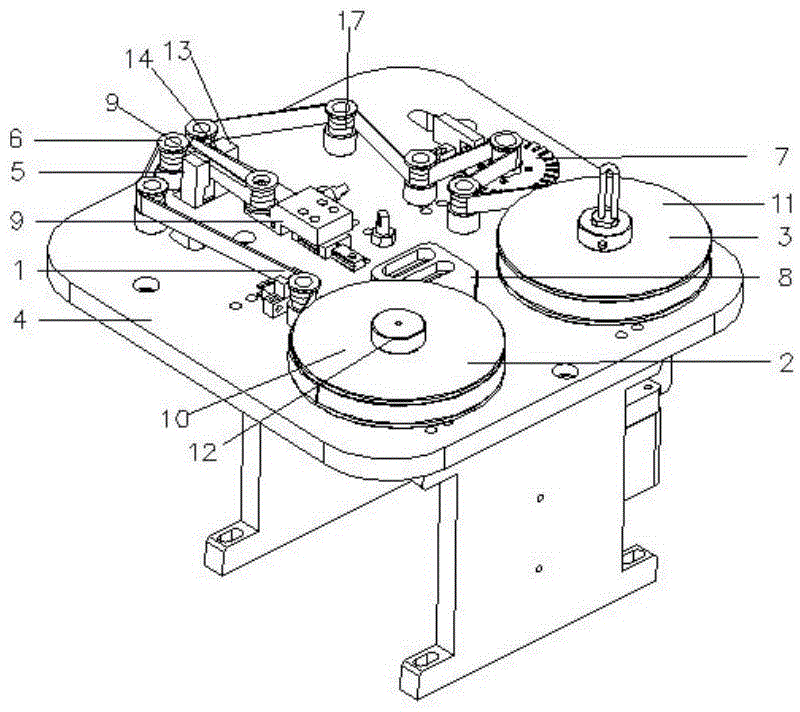

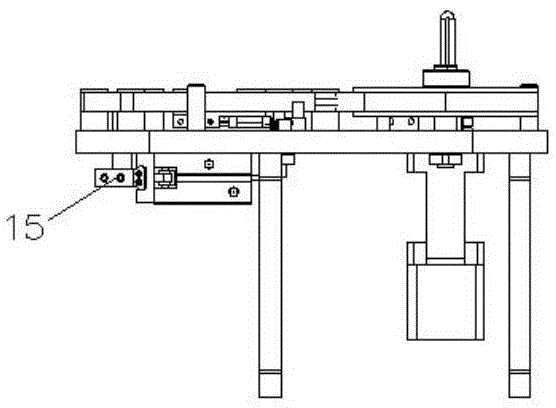

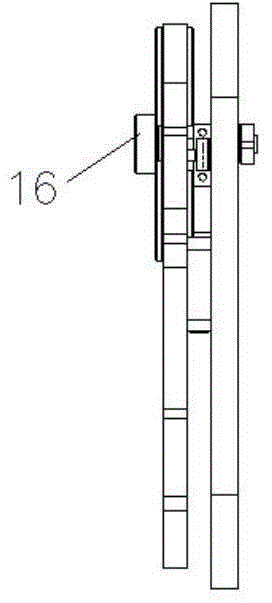

[0030] Such as figure 1 , 2 , A kind of glue wiping machine shown in 3, 4, comprises material belt 1, feeding mechanism 2, receiving mechanism 3, base 4, and described material belt 1 is fixed on the described feeding mechanism 2, passes through described feeding mechanism 2. Transport the material belt 1 so that the material belt 1 is in contact with the parts to be wiped. After the material belt 1 is wiped, it is recovered by the described material receiving mechanism 3, and the described material feeding mechanism 2 and the material receiving mechanism 3 are set On the base 4. After feeding mechanism 2, material belt 1, and material receiving mechanism 3, material belt 1 can be in close contact with the parts to be wiped. At this time, the glue of the parts in contact is wiped clean, and the parts to be wiped can be needles or glued. product. Material band 1 can wipe the relevant materials such as paper, cloth, rubber strip etc. and use.

[0031] The feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com