UV visbreaking protection film for lithium battery packaging, and preparation method thereof

A technology of lithium battery and protective film, applied in the field of UV anti-viscosity protective film for lithium battery packaging and its preparation, can solve the problems of unstable UV anti-viscosity glue, low production efficiency, residual glue, etc., and achieve good economic benefits and technology. Simple, simple coating process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

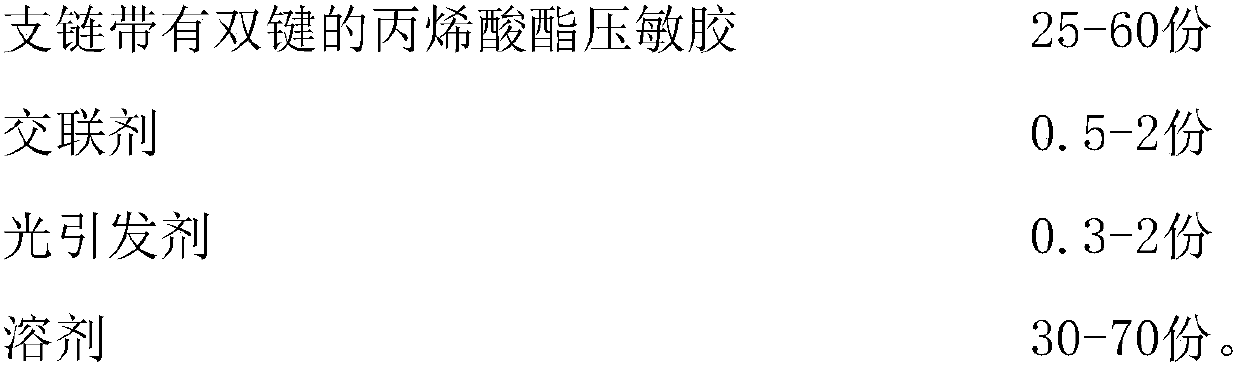

[0033] A UV detackifying protective film for lithium battery packaging, comprising a substrate film, a UV detackifying adhesive layer and a release film arranged in sequence, the UV detackifying adhesive layer is a branched acrylate resin with double bonds. Sensitive adhesive layer, described UV viscosifying adhesive layer is made after drying of UV viscous reducing glue, and described UV viscous reducing glue comprises the raw material of following parts by weight:

[0034]

[0035] The branched acrylate pressure-sensitive adhesive with double bonds is synthesized in the following manner: the branched acrylate pressure-sensitive adhesive containing hydroxyl groups is used as a starting material, and reacted with monoisocyanate acrylate to obtain the branched acrylate pressure-sensitive adhesive with double bonds. Bonded acrylate pressure sensitive adhesive. Add 100kg of branched acrylate pressure-sensitive adhesive containing hydroxyl groups, 2kg of monoisocyanate acrylate...

Embodiment 2

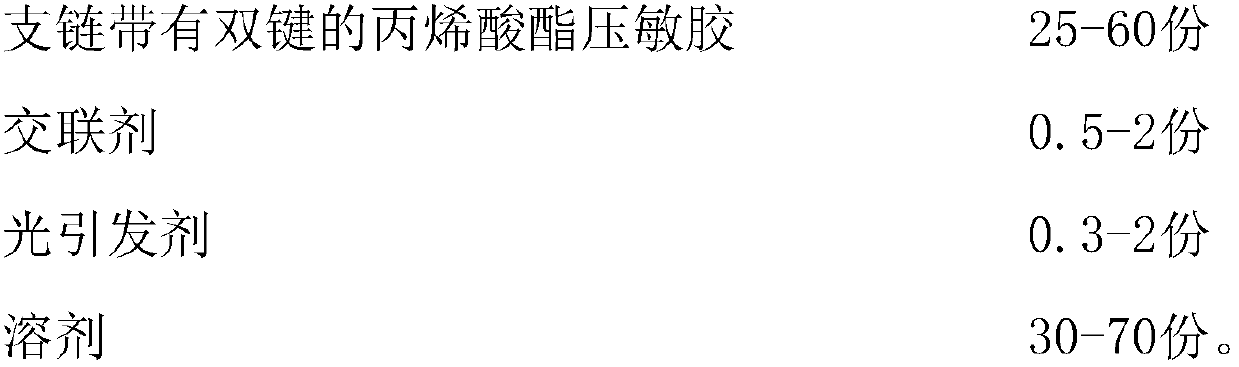

[0047] A UV detackifying protective film for lithium battery packaging, comprising a substrate film, a UV detackifying adhesive layer and a release film arranged in sequence, the UV detackifying adhesive layer is a branched acrylate resin with double bonds. Sensitive adhesive layer, described UV viscosifying adhesive layer is made after drying of UV viscous reducing glue, and described UV viscous reducing glue comprises the raw material of following parts by weight:

[0048]

[0049] The branched acrylate pressure-sensitive adhesive with double bonds is synthesized in the following manner: the branched acrylate pressure-sensitive adhesive containing carboxyl groups is used as a starting material, and reacted with glycidyl methacrylate to obtain the branched acrylate pressure-sensitive adhesive. Acrylic pressure sensitive adhesive with double bonds. Specifically, 100 kg of branched acrylate pressure-sensitive adhesive containing carboxyl groups, 2 kg of glycidyl methacrylate...

Embodiment 3

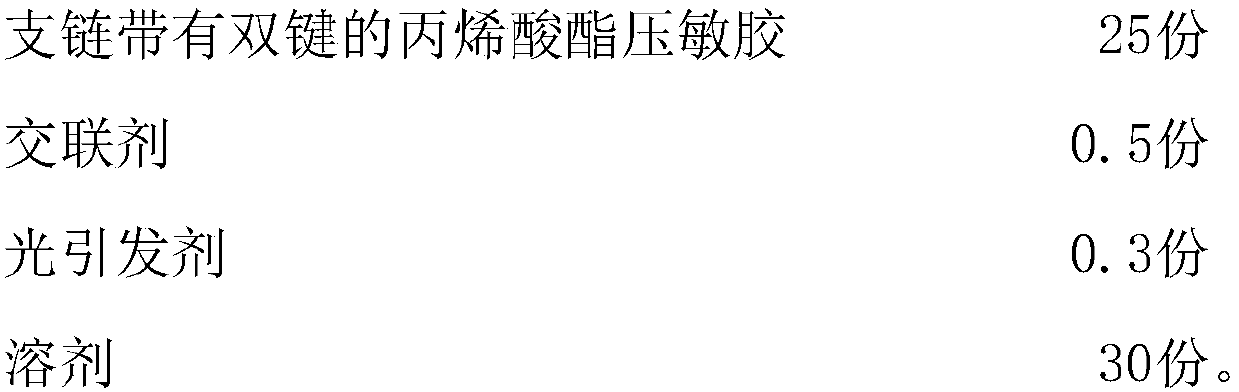

[0061] A UV detackifying protective film for lithium battery packaging, comprising a substrate film, a UV detackifying adhesive layer and a release film arranged in sequence, the UV detackifying adhesive layer is a branched acrylate resin with double bonds. Sensitive adhesive layer, described UV viscosifying adhesive layer is made after drying of UV viscous reducing glue, and described UV viscous reducing glue comprises the raw material of following parts by weight:

[0062]

[0063] The branched acrylate pressure-sensitive adhesive with double bonds is synthesized in the following manner: the branched acrylate pressure-sensitive adhesive containing hydroxyl groups is used as a starting material, and reacted with monoisocyanate acrylate to obtain the branched acrylate pressure-sensitive adhesive with double bonds. Bonded acrylate pressure sensitive adhesive. Add 100kg of branched acrylate pressure-sensitive adhesive containing hydroxyl groups, 5kg of monoisocyanate acrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com