A method for processing through-groove of rigid-flex board

A technology of rigid-flex boards and processing methods, which is applied in the manufacture of multi-layer circuits, etc., can solve the problems of gasket falling off, cumbersome operations of taking and placing gaskets, etc., and achieve the effect of simplifying the production problem and solving the problem of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for processing a through-groove of a rigid-flexible board, comprising the following steps,

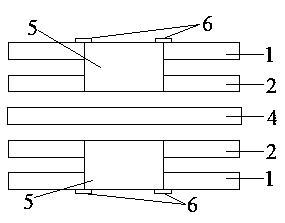

[0025] S1. If Figure 5 , 6 In the process, pass through the groove for No-flow prepreg 20 times, take out the prepreg in the groove after passing through the groove for No-flow prepreg 20 times; Bridge point 60 is set in the area other than the outline line, the bridge point 60 does not open the groove, and the other positions between the sub-core board 10 and the gasket 50 except the bridge point 60 open the groove;

[0026] In this embodiment, the width of the bridge point 60 is 2-10 mm. The width of 2-10mm can not only ensure the link between the gasket 50 and the edge of the groove, but also can easily break the bridge point 60 by the gong machine during the subsequent process of breaking the bridge, and the gasket 50 will fall off naturally, which solves the problem. Solve the problem of adhesive tape residue on the edge of the groove, and simplify the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com