Circuit board and manufacturing method thereof

A production method and circuit board technology, which is applied in the direction of multilayer circuit manufacturing, printed circuit, electrical components, etc., to achieve the effect of improving joint reliability, avoiding the problem of residual glue, and reducing the thickness of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

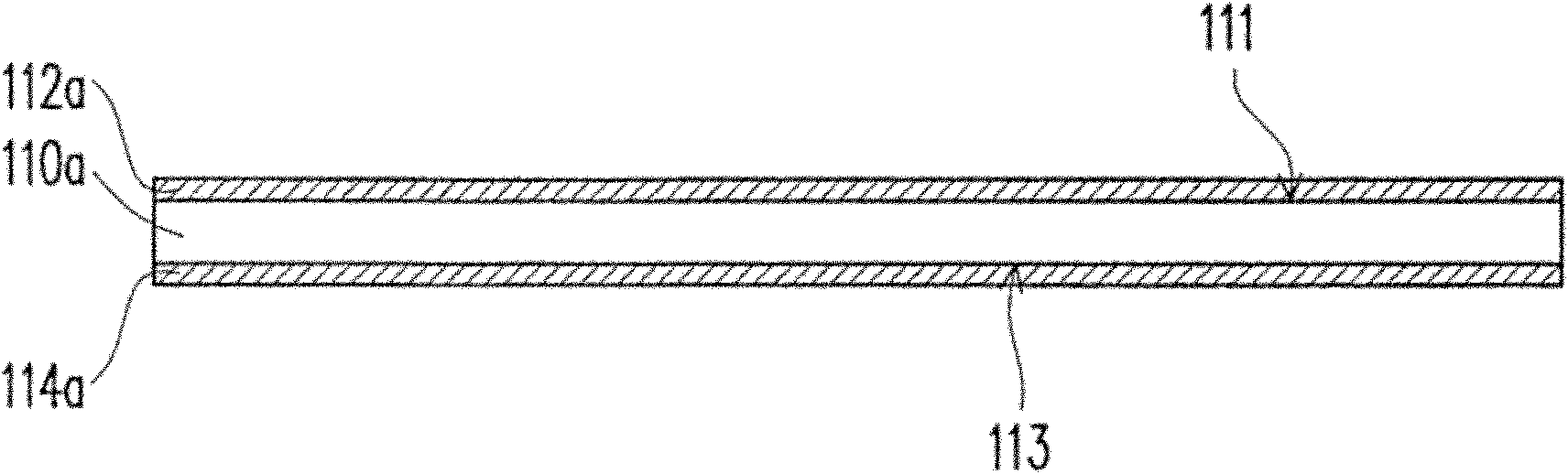

[0043] Figure 1A to Figure 1G It is a schematic cross-sectional flow diagram of a method for manufacturing a circuit board according to an embodiment of the present invention. Please refer to Figure 1A , The manufacturing method of the circuit board of this embodiment includes the following steps. First, a base layer 110a is provided, wherein the base layer 110a has a first surface 111 and a second surface 113 opposite to each other, and the base layer 110a is, for example, a core dielectric layer.

[0044] Next, please refer to Figure 1A , respectively forming the first core circuit layer 112a and the second core circuit layer 114a on the first surface 111 and the second surface 113 of the core dielectric layer (ie, the base layer 110a ).

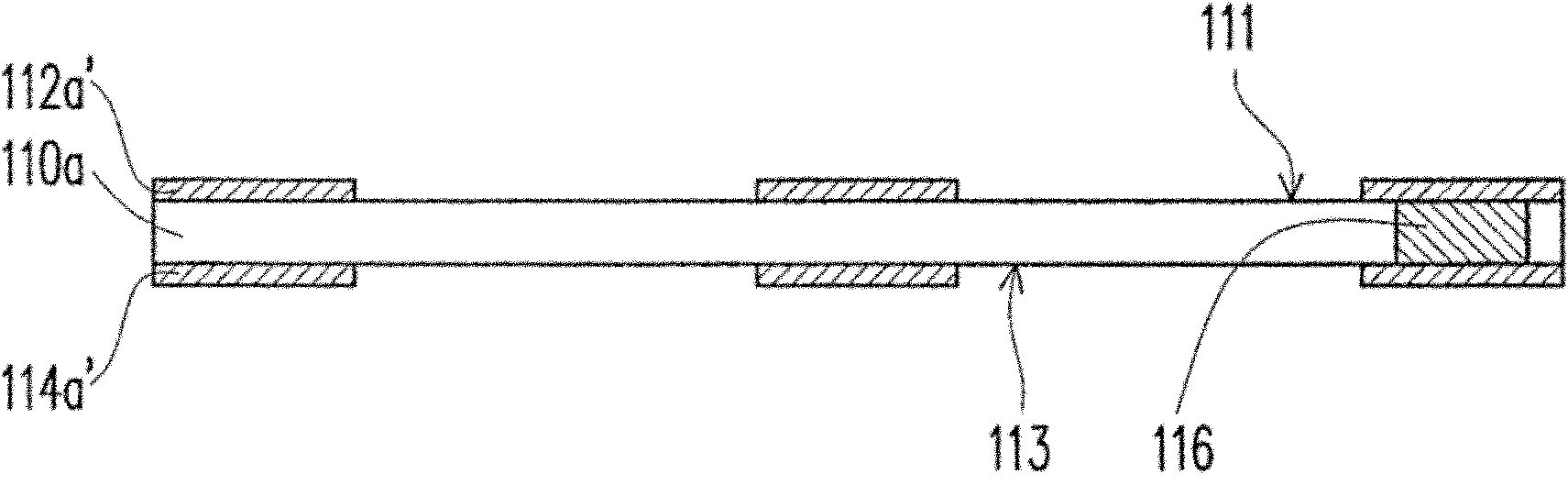

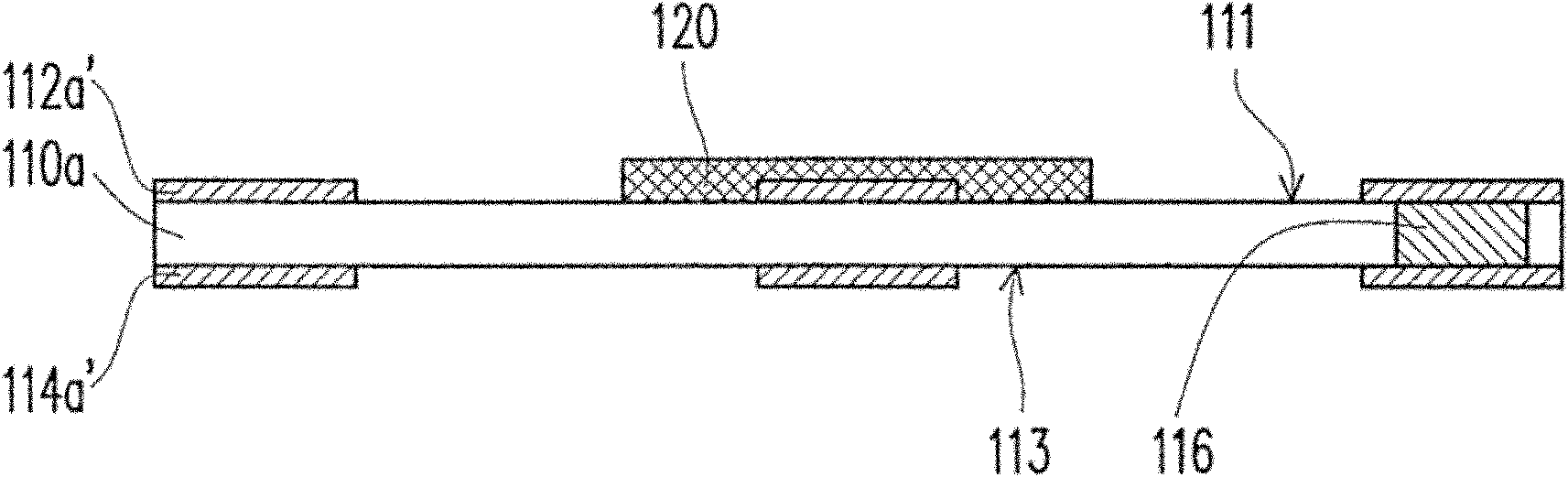

[0045] Next, please refer to Figure 1B , sequentially perform a drilling process and an electroplating filling process to form at least one conductive via structure 116 connecting the first surface 111 and the second surface 113 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com