Dispensing and assembling apparatus

A technology for assembling equipment and dispensing, which is applied to the device and coating of the surface coating liquid, which can solve the problems of glue dispensing, dripping, etc., achieve the effect of precise dispensing and assembly, and solve the problem of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

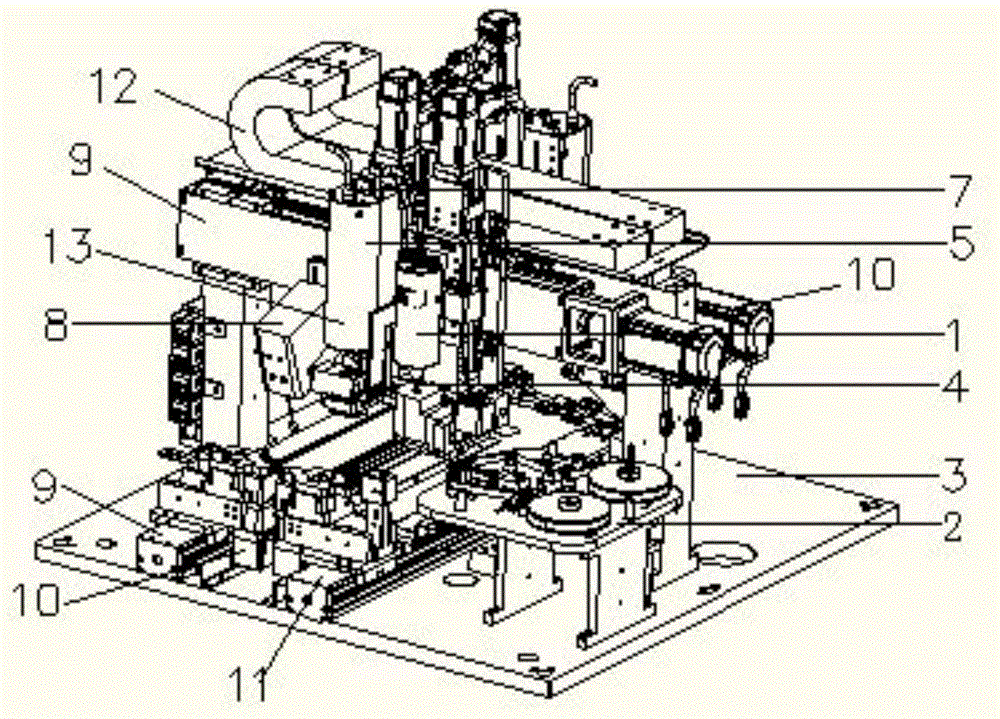

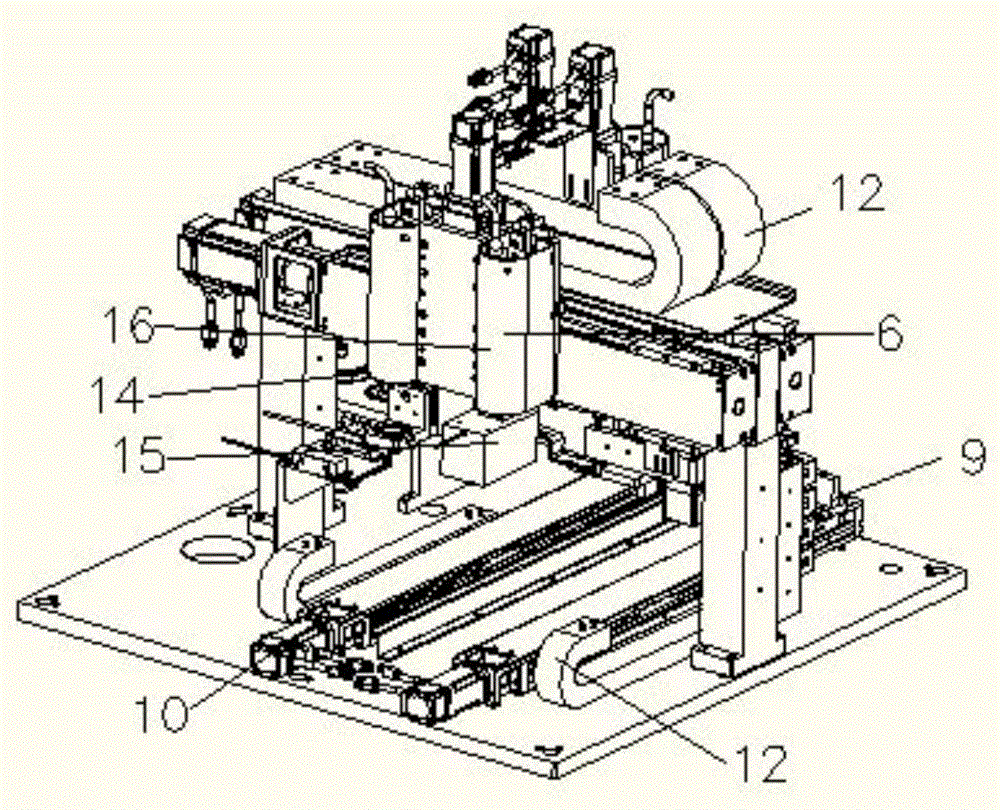

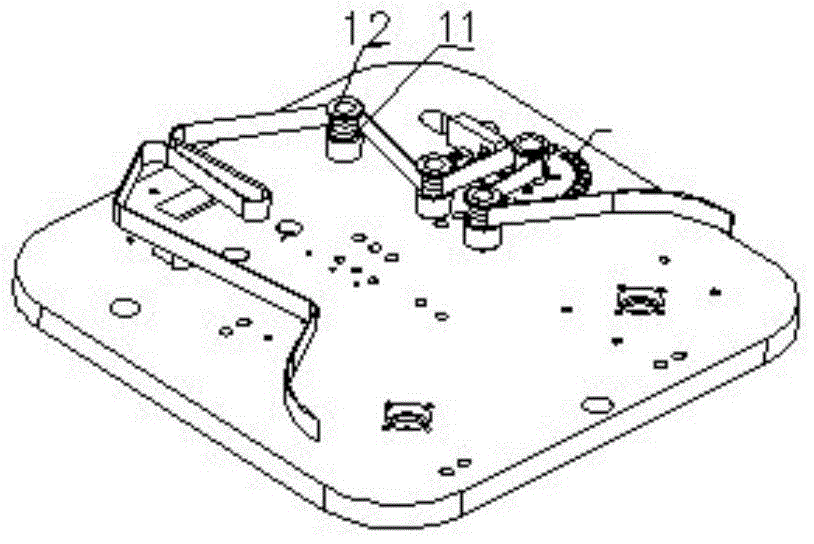

[0025] like figure 1 , 2 A kind of glue dispensing assembly equipment shown, comprises glue dispensing module 1, rubbing glue module 2, table top 3, described glue dispensing module 1 is also provided with needle 4, and described glue dispensing module 1 moves to Above the glue wiping module 2, the glue wiping module 2 wipes the needle 4 of the dispensing module, and is located on the table 3 with the glue wiping module 2 , through the rubber wiping module 2 to wipe the needle 4 to solve the problem of residual glue.

[0026] The suction camera module 5 is located at the side of the dispensing module 1, and the suction camera module 5 is used to take pictures of products. Conducive to more accurate dispensing and assembly.

[0027] The calibration module 6 is set on the table 3, and the dispensing module 1 moves to the calibration module 6 to realize the position calibration of the needle 4 of the dispensing module 1. Calibrate pin 4.

[0028] There are several linear mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com