Release film, protective film and display device

A technology of release film and protective film, which is applied in the field of materials, can solve the problems of long curing time of the adhesive layer, achieve the effects of shortening the curing time, stable performance, and avoiding the problem of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The production process of the protective film includes:

[0053] First, make a release film.

[0054] The mixture of the matrix and the protruding particles is coated on the surface of the release base material layer by a dimple coating method, and a release layer is formed on the surface of the release base material layer, thereby forming a release film.

[0055] Next, the raw material of the adhesive layer is coated on the surface of the protective substrate layer to form an adhesive layer.

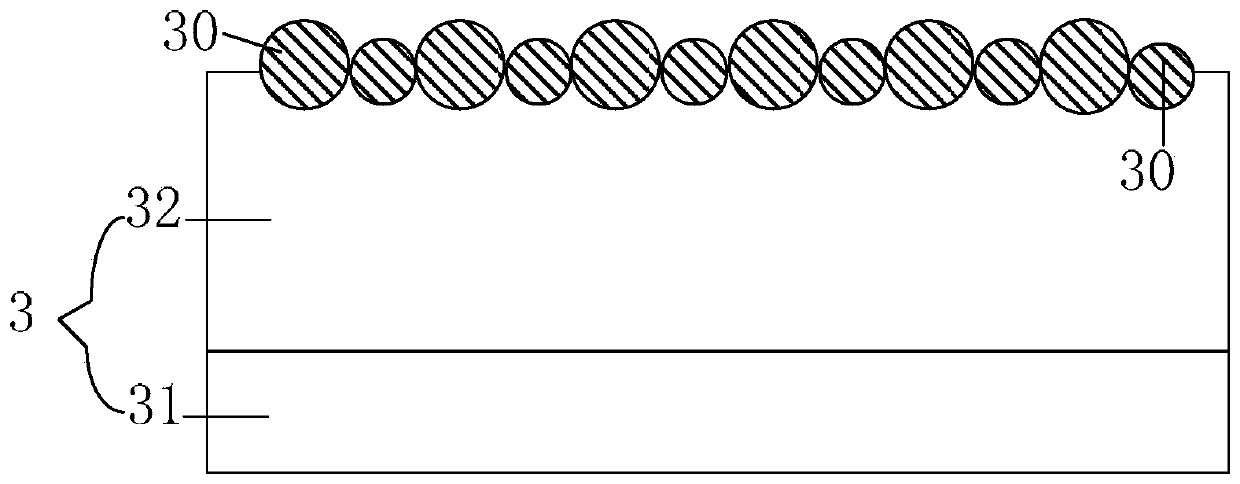

[0056] Finally, the release film is attached to the adhesive layer on the surface of the protective substrate layer and cured under constant humidity conditions at 50°C to form a protective film, forming a protective substrate layer, an adhesive layer, and a release layer in order from bottom to top. The release substrate layer, wherein the structure of the release film is as figure 1 shown.

[0057] Among them, the protective substrate layer and the release substrate layer ar...

Embodiment 2

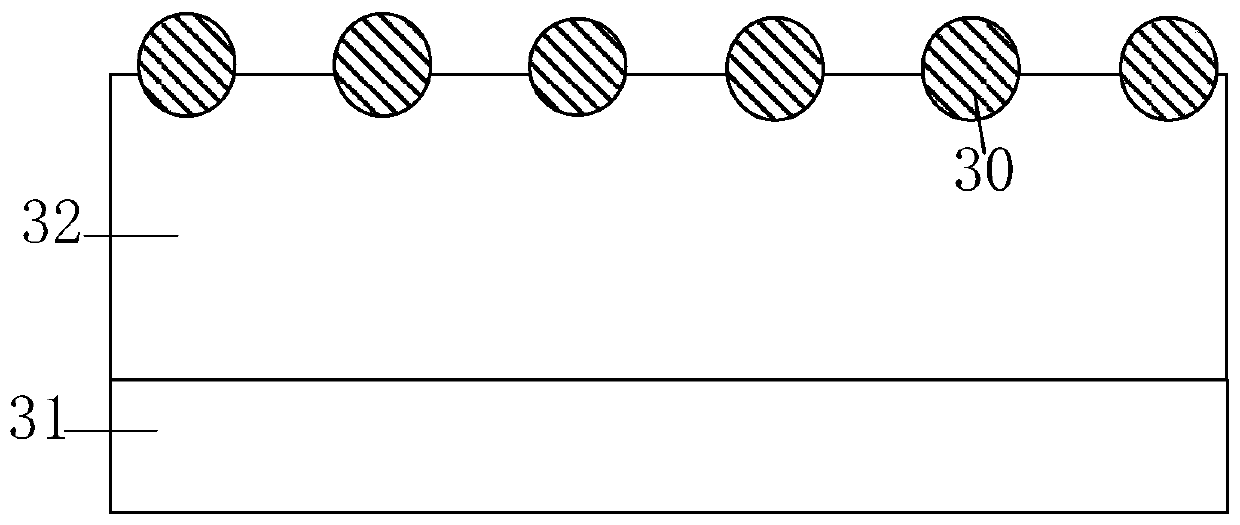

[0059] The difference with Example 1 is that the structure of the formed release film is as image 3 As shown, the protruding particles are PU particles with a particle size between 10 and 13 μm.

Embodiment 3

[0061] The difference from Example 2 is that the particle size of the PU particles is between 5-8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com