Multilayer gently-inclined extremely-narrow vein stoping blasting technology

An extremely thin ore and gently inclined technology, applied in blasting, ground mining, earth square drilling and mining, etc., can solve the problems of reducing ore dilution rate and surrounding rock mixing, and achieve the effect of reducing dilution rate and avoiding mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

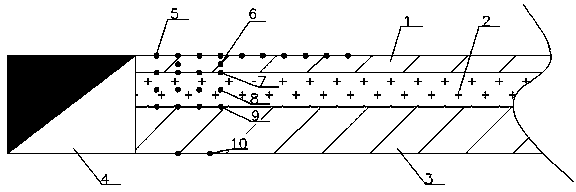

[0022] In order to further describe the present invention, a multi-layer gently inclined extremely thin vein recovery blasting technology of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Depend on figure 1 It can be seen from the blast hole layout schematic diagram of a kind of multi-layer gently inclined extremely thin vein mining blasting technology shown in the present invention that the present invention adopts top-to-bottom mining, layer-by-layer detonation from top to bottom, and each layer blasting Hole arrangements and charge forms vary.

[0024] In the present invention, a cutting roadway 4 is excavated next to the mined multi-layered veins as a compensation space when the ore body is mined. The cutting roadway 4 excavates the first layered veins 1, the rock interlayer 2, and the second layered veins 3 all at once.

[0025] Next, excavate intensive blastholes 5 at the boundary between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com