Household garbage fermentation and fertilizer making device and method

A technology for domestic waste and fermentation bins, applied in organic fertilizers, climate change adaptation, etc., can solve the problems of fermentation time being limited by seasons and climates, affecting the environment of surrounding areas, and covering a large area, so as to shorten the drying time, Improve composting efficiency and maturity, with small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

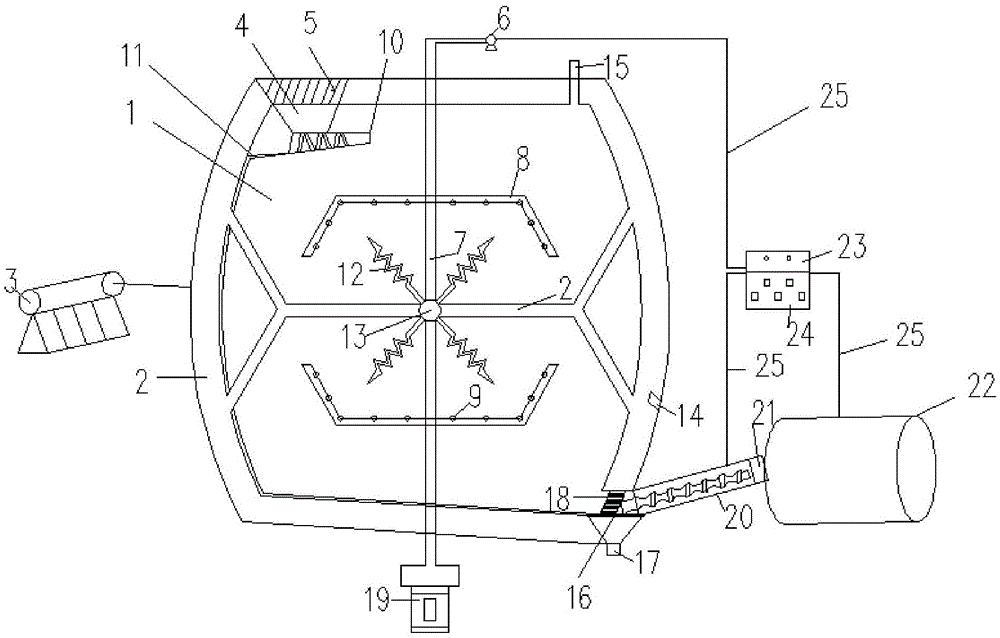

[0024] Such as figure 1 As shown, a domestic waste fermentation and fertilizer production device, the main body of the device is a fermentation bin 1, a feed port 4 and an exhaust port 15 opened in the upper part of the fermentation bin 1, and a feed baffle 5 is set at the feed port 4; A liquid outlet 17 for discharging percolate and a material outlet 21 for outputting fermented materials are opened in the lower part of the fermentation bin 1; a crushing device is provided in the fermentation bin 1. The bottom of the fermentation bin 1 is inclined, and the liquid outlet 17 and the feed inlet 4 are arranged near the lowest point. The exhaust port 15 can be connected to the deodorizing tower through an external exhaust machine.

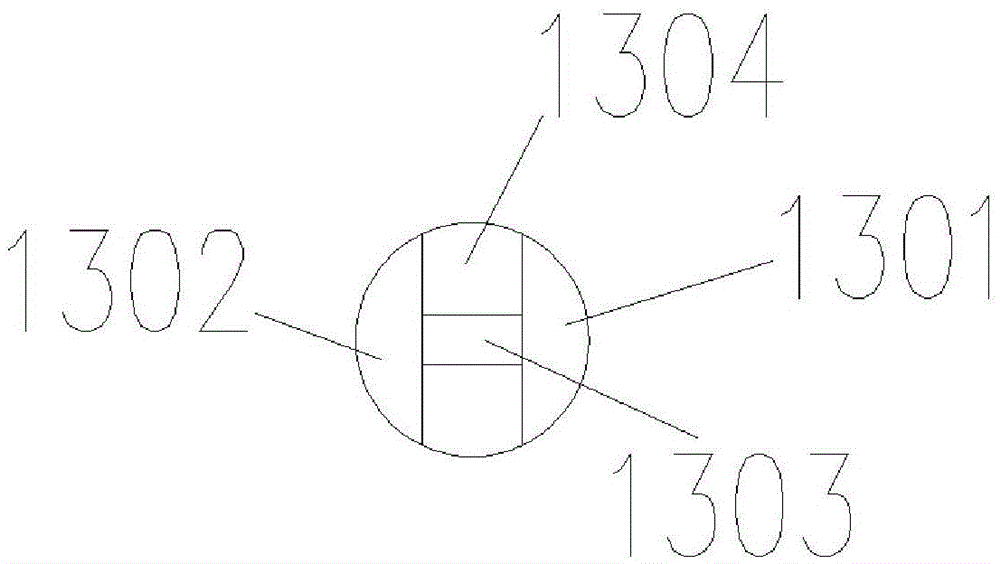

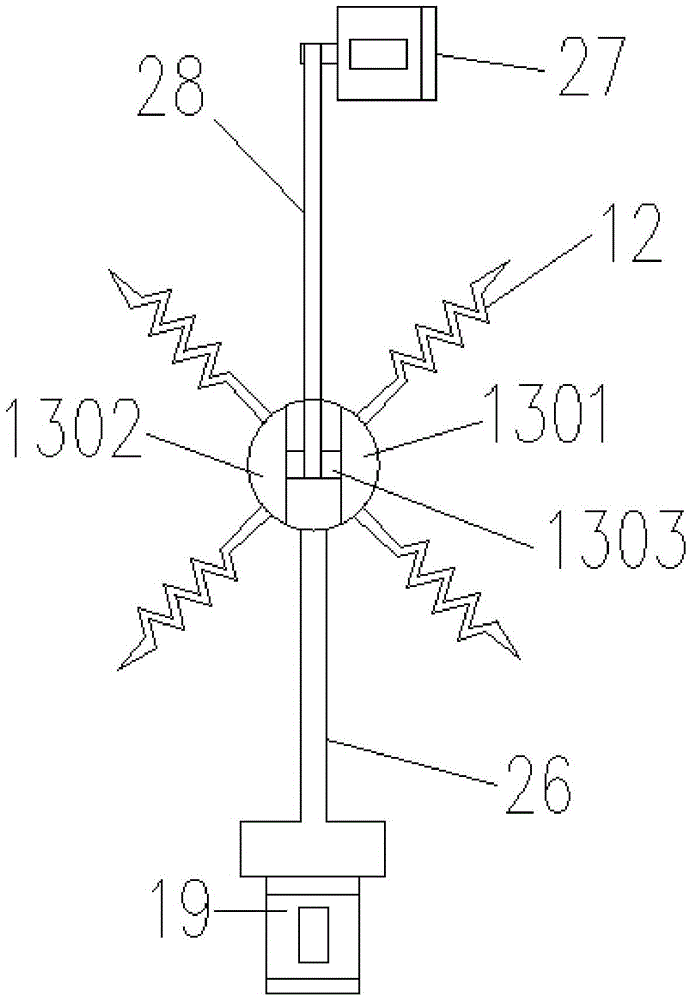

[0025] The crushing device is a plurality of groups of crushing blades 12 arranged in a cross shape, with two mutually perpendicular rotation dimensions. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com