Mining method for treating goaf remaining intervening pillar by filling method

A mining method and goaf technology, which are applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of increasing the amount of quasi-cutting works, unable to form through-air flow, and difficulty in ventilation of the working face, so as to control the exposure of the stope. Scale, reducing the mixing rate of waste rock and ore dilution rate, and the effect of reducing the ore dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

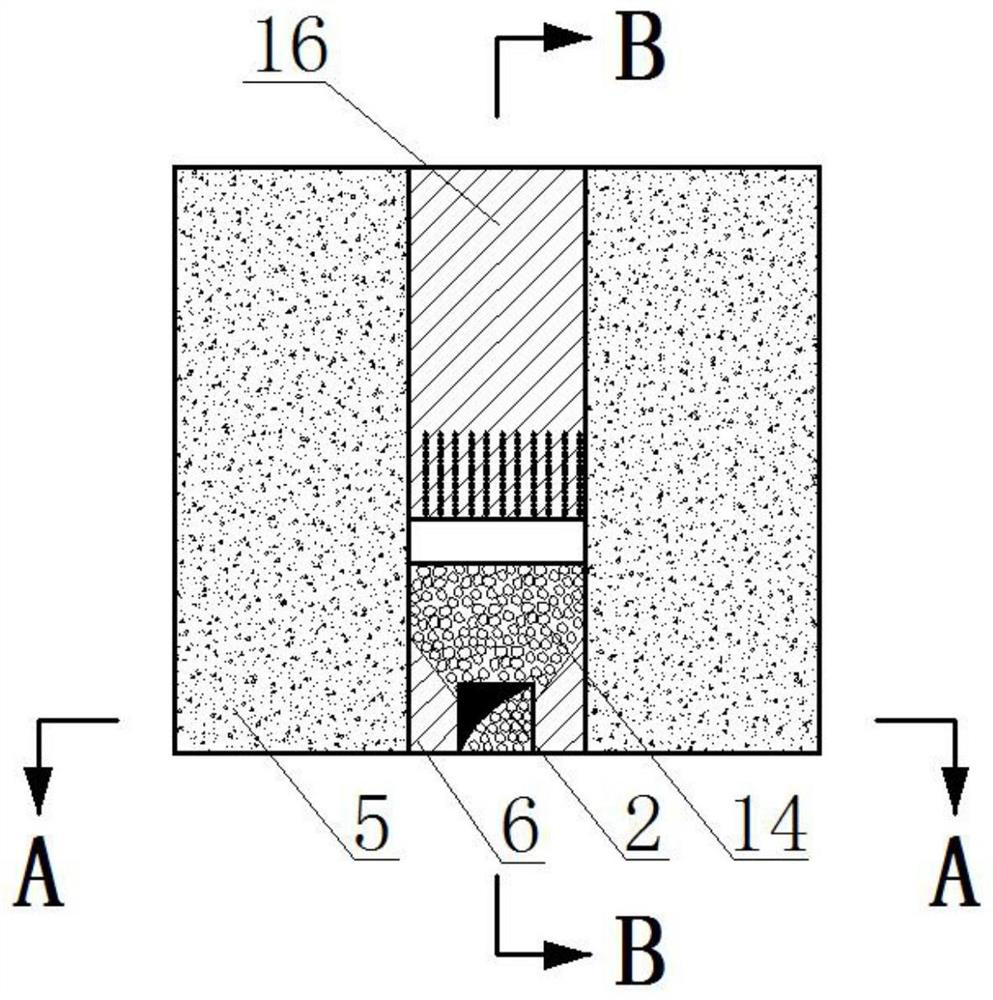

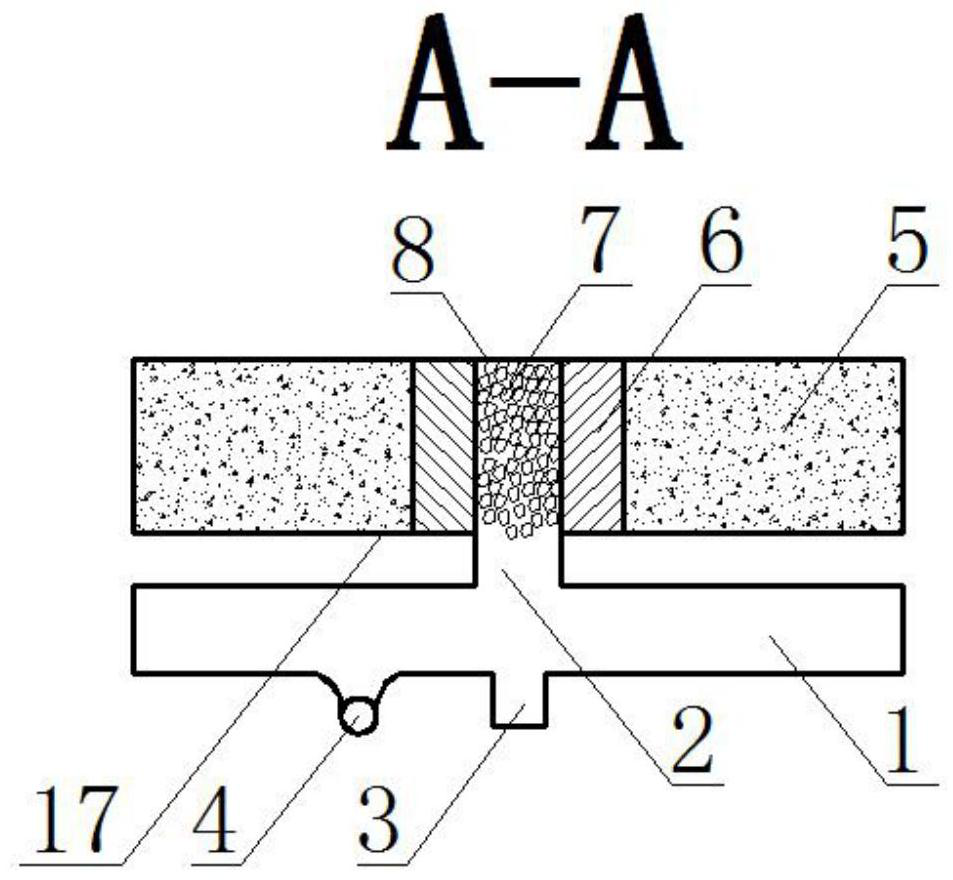

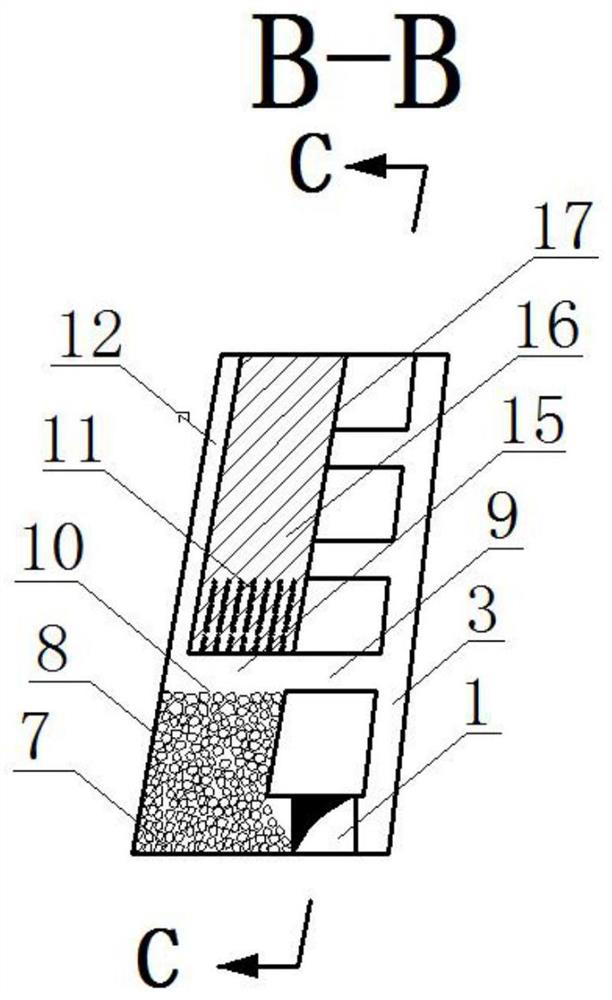

[0034] In order to better describe the present invention, a mining method of the present invention for processing leftover columns in goafs by filling method will be further described in detail below in conjunction with the accompanying drawings.

[0035] Depend on figure 1 The front view of a mining method of the present invention that is used to process the remaining spacers in the goaf with the filling method and combined figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 It can be seen that the present invention is a kind of mining method for filling method to process the leftover spacers in the goaf, the ore body is provided with spacers 16, the two sides of spacer 16 are mining houses, and the middle section transportation roadway is provided at the footwall of the ore body 1. Specifically, the following steps are implemented:

[0036] 1) In the footwall surrounding rock 13 on the side of the transport roadway 1 in the middle section of the footwall of the ore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com