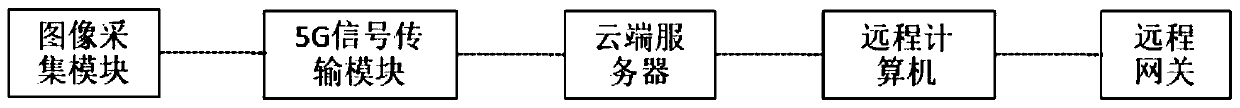

Slitting roof cutting stoping method used for precontrolled roof house pillar method

A pre-control roof and roof cutting technology, which is applied in ground mining, mining equipment, mining equipment, etc., can solve the problems of difficult roof management, high mining loss rate, high ore dilution rate, high mining and cutting engineering volume and high direct cost of mining, etc. problem, to achieve the effect of increasing integrity and self-supporting ability, improving safety and resource recovery rate, and reducing the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

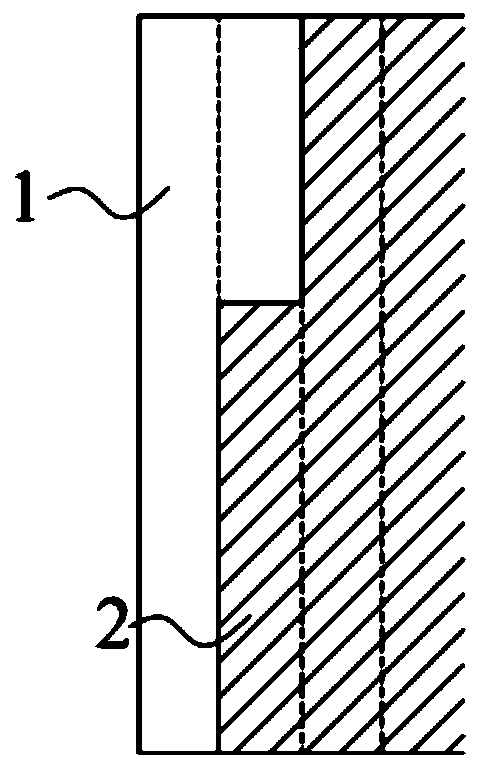

[0086] A roof support method, specifically comprising the following steps:

[0087] - Drill the anchor hole on the roof with the drilling equipment, the anchor hole diameter is 33mm, the hole length = the anchor length - 0.1m, and clean the inner wall of the hole to meet the requirements;

[0088] - Put the model Z2350 resin anchoring agent package in the anchor hole;

[0089] -Use a rotatable device to place the threaded anchor rod including the outer anchor rod body and the pointed head in the anchor rod hole, forcing the pointed head to pierce the resin anchoring agent package; the resin anchor rod is arranged in a plum blossom shape, and the diameter of the anchor rod is 20mm, Length 2.5m, spacing 1.6m;

[0090] - Rotate the anchor rod body at 300r / min to mix the resin anchoring agent until the resin anchoring agent is solidified on the inner wall of the anchor rod hole and the outer surface of the anchor rod body;

[0091] -Install steel strips and pallets, and hang rei...

Embodiment 2

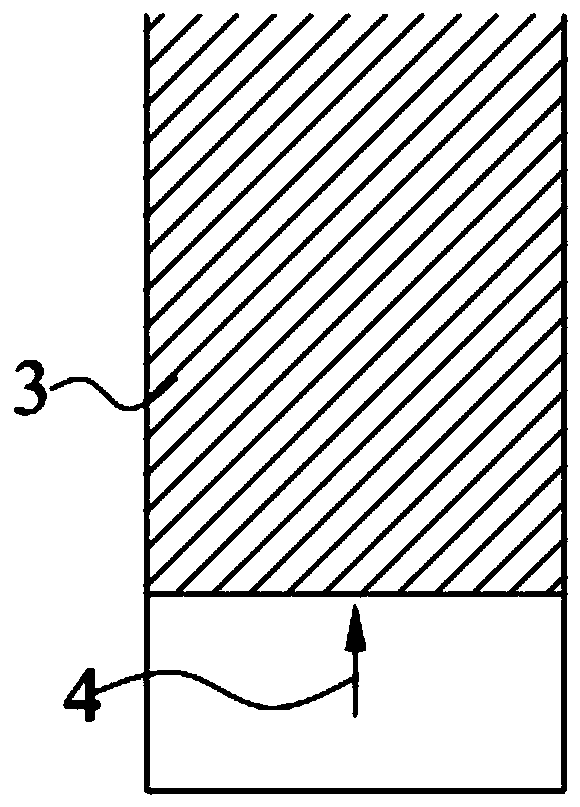

[0097] The difference with embodiment 1 is: a kind of roof support method, used shotcrete also comprises with respect to cement with relative mass parts: 0.11 part of sodium alizarin sulfonate.

Embodiment 3

[0099] The difference from Example 2 is: a roof support method, the resin anchoring agent is placed in the hole of the anchor rod and glass powder and brassinolide are inserted at the same time, the particle size D50 of the glass powder is 5.6 μm, D90 is 31.4 μm. The addition of glass powder is 1.2wt% of the weight of the resin anchoring agent, and the addition of brassinolide is 0.08wt% of the weight of the resin anchoring agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com