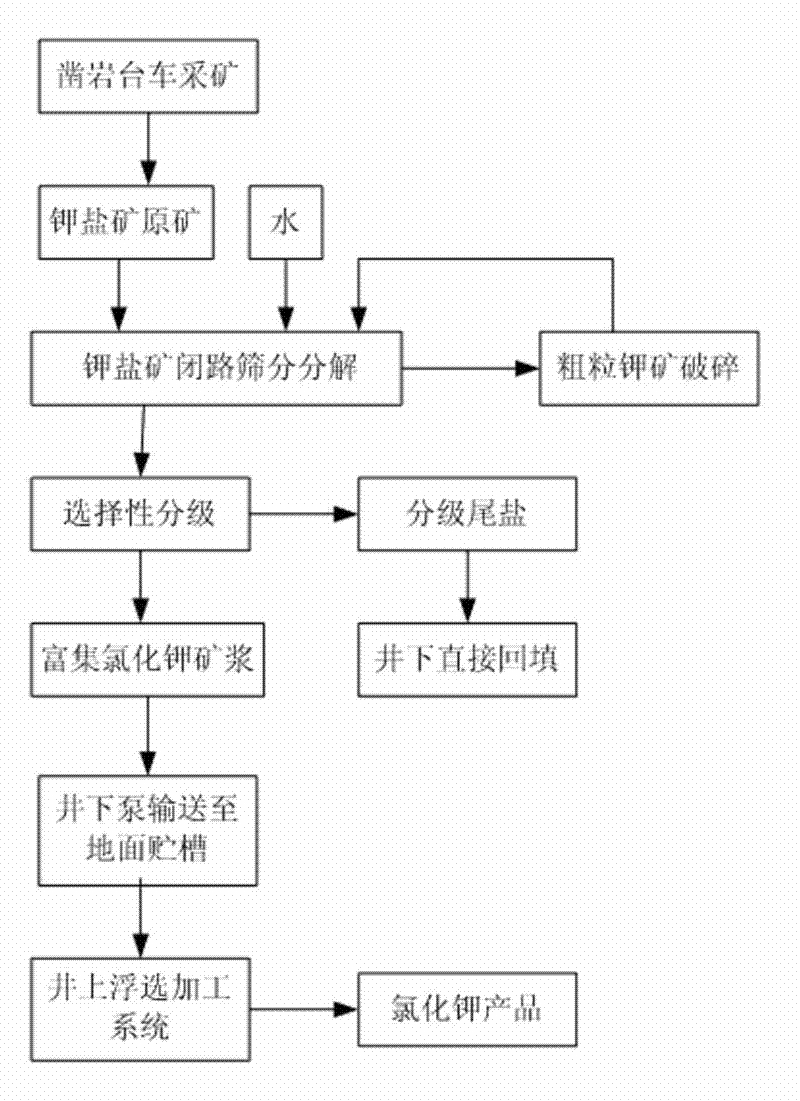

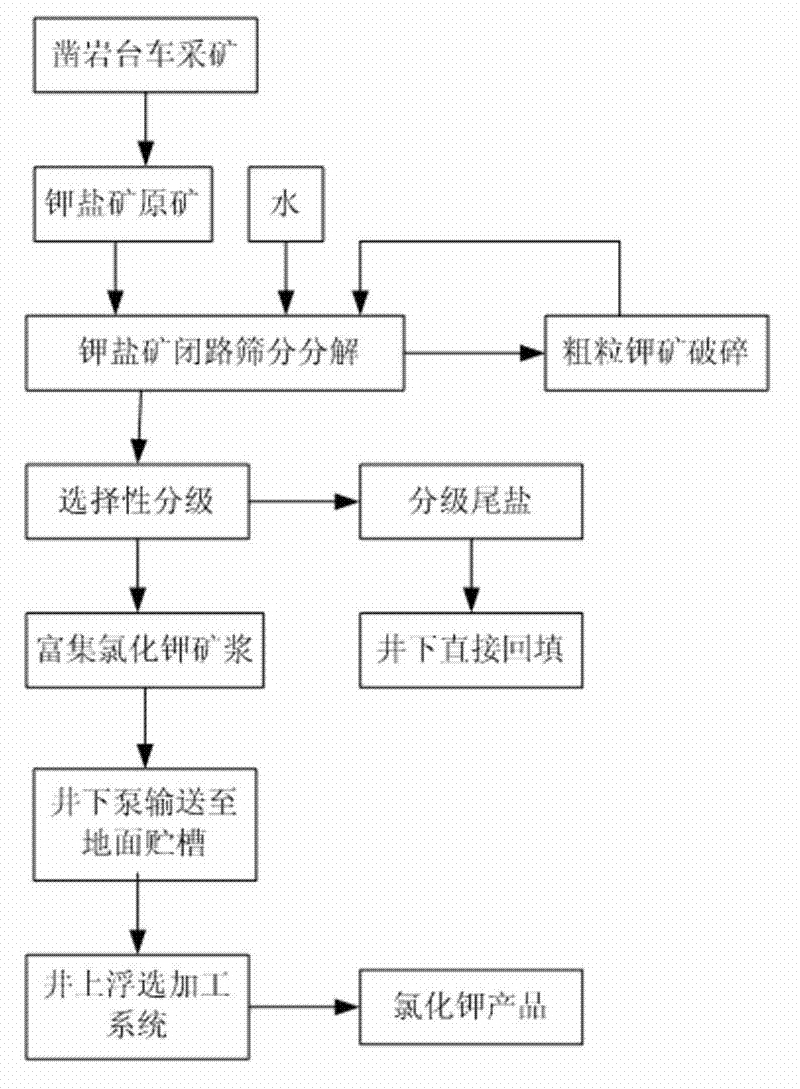

Method for producing enriched potassium chloride by downhole fractional decomposition of solid potash salt ore

A production method and technology of potassium chloride, applied in the direction of alkali metal chloride, etc., can solve the problems of limited mining lifting capacity, unstable ore properties, easy weathering and deliquescence, etc., and achieve reduced mining lifting costs, large production capacity, and high production capacity. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Raw ore input is 1.00 tons / hour.

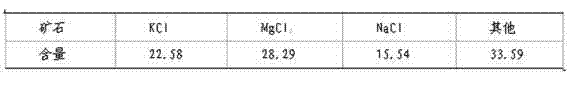

[0025] (1) The chemical composition of the comprehensive ore sample is:

[0026]

[0027] (2) Closed-circuit screening and decomposition

[0028] The purpose of closed-circuit screening and decomposition is to control the particle size of the raw ore within 10mm through wet screening. The raw ore larger than 10mm is 15% of the ore input. After closed-circuit crushing and screening, the final raw ore particle size is -10mm and directly enters the decomposition. The amount of water added for screening and decomposition is 0.30 tons / hour, the circulating mother liquor is 0.38 tons / hour, the produced slurry is 1.68 tons / hour, and the raw ore decomposition rate is 90.17%.

[0029] (3) Selective grading

[0030] The slurry produced by closed-circuit screening and decomposition is selectively classified to obtain enriched fine-grained potassium chloride. The slurry volume is 1.41 tons / hour, the slurry concentration is 14.72%, and the pot...

Embodiment 2

[0032] Raw ore input is 1.00 tons / hour.

[0033] (1) The chemical composition of the comprehensive ore sample is:

[0034]

[0035] (2) Closed-circuit screening and decomposition

[0036] The purpose of closed-circuit screening and decomposition is to control the particle size of raw ore within 10mm through wet screening, and the raw ore larger than 10mm is 13.76% of the ore input. After closed-circuit crushing and screening, the final raw ore particle size is -10mm and directly enters decomposition. The amount of water added for screening and decomposition is 0.39 tons per hour, the resulting slurry is 1.39 tons per hour, and the raw ore decomposition rate is 94.31%.

[0037] (3) Selective grading

[0038] The slurry produced by closed-circuit screening and decomposition is selectively classified to obtain enriched fine-grained potassium chloride. The slurry volume is 1.23 tons / hour, the slurry concentration is 15.75%, and the potassium chloride content of solids in the ...

Embodiment 3

[0040] The raw ore feeding rate is 2.00 tons / hour.

[0041] (1) The chemical composition of the comprehensive ore sample is:

[0042]

[0043] (2) Closed-circuit screening and decomposition

[0044] The purpose of closed-circuit screening and decomposition is to control the particle size of the raw ore within 10mm through wet screening. The raw ore larger than 10mm is 15.5% of the ore input. After closed-circuit crushing and screening, the final raw ore particle size is -10mm and directly enters the decomposition Screening and Decomposition The amount of water added for decomposition is 0.94 tons / hour, the resulting slurry is 2.94 tons / hour, and the decomposition rate of raw ore is 97.28%.

[0045] (3) Selective grading

[0046]The slurry produced by closed-circuit screening and decomposition is selectively classified to obtain enriched fine-grained potassium chloride. The slurry volume is 2.73 tons / hour, the slurry concentration is 17.23%, and the potassium chloride cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com