Mineral separation and enrichment method for molybdenum oxide ores

A molybdenum oxide and enrichment technology is applied in the direction of solid separation, recycling technology, mechanical material recovery, etc. It can solve the problems of poor buoyancy, low recovery rate, and more molybdenum loss, so as to reduce the grade, reduce the amount of addition, The effect of reducing the pressure of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

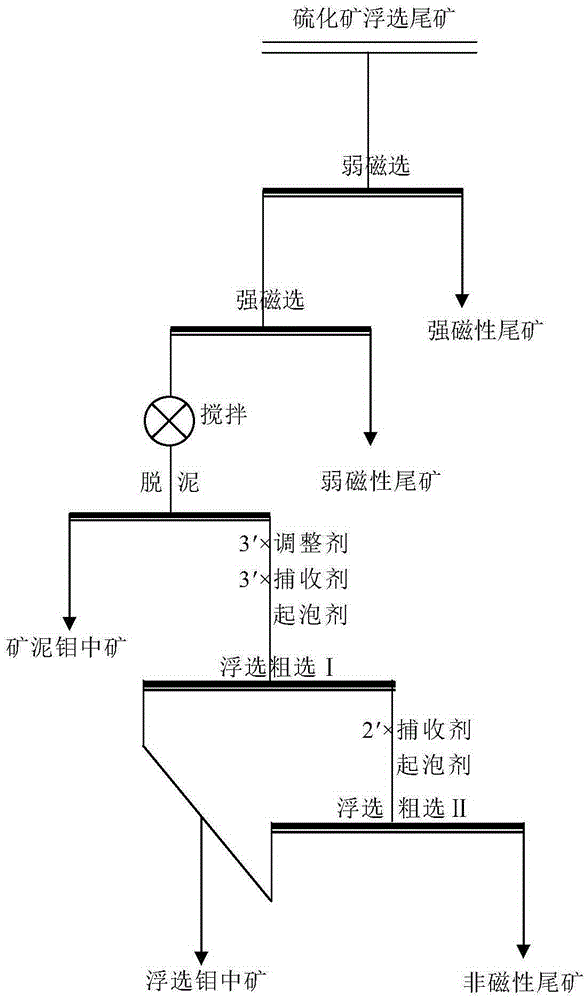

Image

Examples

Embodiment 1

[0042] The molybdenum grade of sulfide ore flotation tailings is 0.066%, and the strong magnetic minerals are removed by drum-shaped wet weak magnetic separator (field strength 1400Oe), and the weak magnetic minerals are selected by high-gradient pulsating strong magnetic separator (field strength 11000Oe) , The yield of strong magnetic minerals is 0.86%, the grade of molybdenum is 0.014%, the yield of weak magnetic minerals is 66.58%, the grade of molybdenum is 0.018%, the total yield of magnetic mineral tailings is 67.44%, the grade of molybdenum is 0.018%, and the yield of the remaining non-magnetic minerals is 32.56% , molybdenum grade 0.17%, molybdenum magnetic separation recovery rate 82.01%, molybdenum minerals are preliminarily enriched in non-magnetic minerals.

[0043] The non-magnetic minerals obtained by the magnetic separation process are used as the ore, and the concentration of the pulp is adjusted to 6-10%. The recovery rate of the operation is 61.90%; the pulp...

Embodiment 2

[0046] The sulfide ore flotation tailings were subjected to the same weak magnetic separation and strong magnetic separation operations as in Example 1 to obtain magnetic mineral tailings with a yield of 67.44% and a molybdenum grade of 0.018%, and a yield of 32.56% with a molybdenum grade of 0.17% and a molybdenum grade of 0.17%. Non-magnetic minerals with a recovery rate of 82.01%.

[0047] The non-magnetic minerals obtained by the weak magnetic separation and strong magnetic separation process are used as the ore, and the concentration of the slurry is adjusted to 10-12%. , The operating recovery rate of molybdenum is 62.88%; the pulp after desliming is in a 3L flotation machine, the concentration of the pulp is adjusted to 12-20%, and the pH is adjusted to 8.0 with soda ash, and 40g / t and 20g / t are added respectively t of benzohydroxamic acid and 20g / t and 10g / t of terpineol oil are used as collectors and foaming agents. After two rough separations, flotation molybdenum wi...

Embodiment 3

[0050] The sulfide ore flotation tailings were subjected to the same weak magnetic separation and strong magnetic separation operations as in Example 1 to obtain magnetic mineral tailings with a yield of 67.44% and a molybdenum grade of 0.018%, and a yield of 32.56% with a molybdenum grade of 0.17% and a molybdenum grade of 0.17%. Non-magnetic minerals with a recovery rate of 82.01%.

[0051] Use the non-magnetic minerals obtained by the weak magnetic separation and strong magnetic separation process as the ore feed, adjust the pulp concentration to 12-20% in the 3L flotation machine, and use the water glass with an amount of 500g / t to the ore as the slime dispersant , soda ash as a regulator to adjust the pH to 8.0, 50g / t, 25g / t of benzohydroxamic acid and 20g / t, 10g / t of methyl isobutyl carbinol (MIBC) were added as collectors and Foaming agent, after two rough separations, the flotation molybdenum medium ore with a yield of 9.81% and a molybdenum grade of 0.33% was obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com