Flotation separation technology for high-sulfur lead-zinc ore in high-concentration environment

A high-concentration, lead-zinc ore technology, applied in flotation, solid separation, wet separation, etc., can solve the problems of low recovery rate of associated gold and silver, high cost and energy consumption of beneficiation, and unstable flotation process. The effect of shortening the buoyancy distance, strengthening the action ability, and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

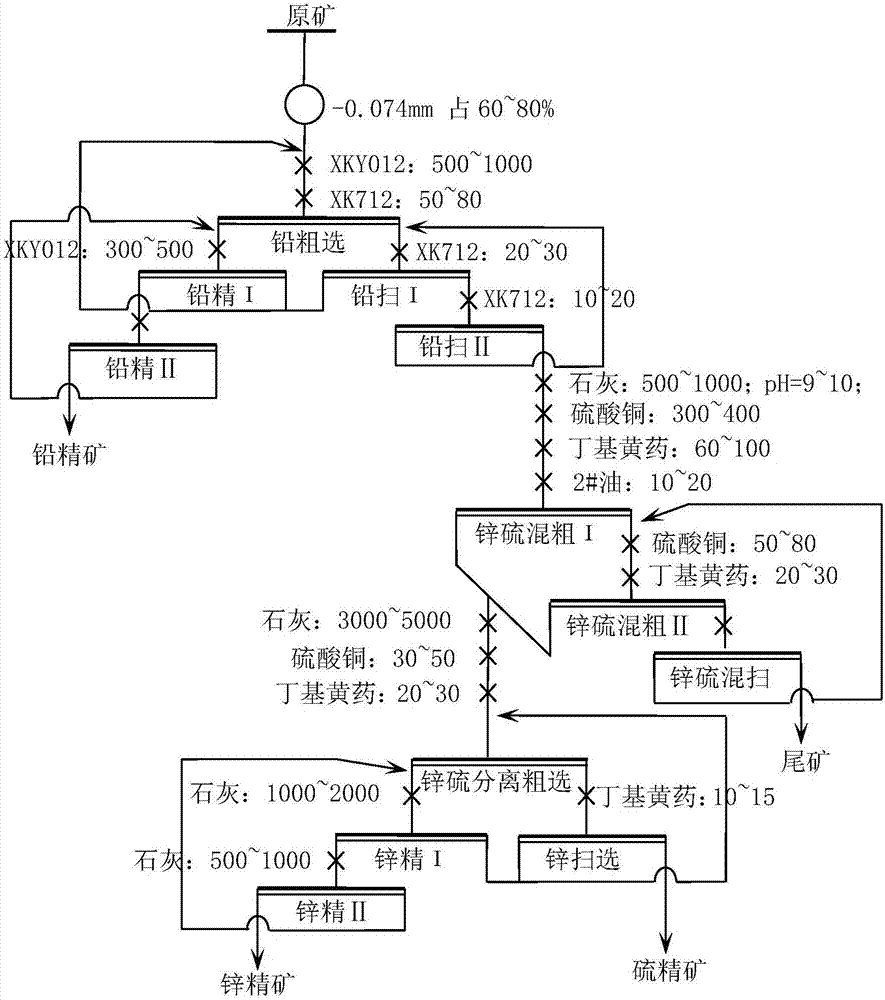

Method used

Image

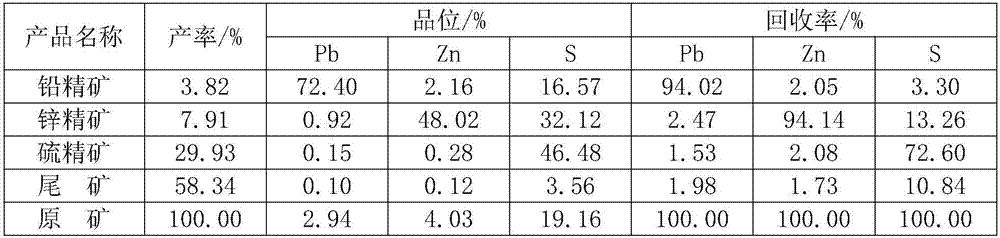

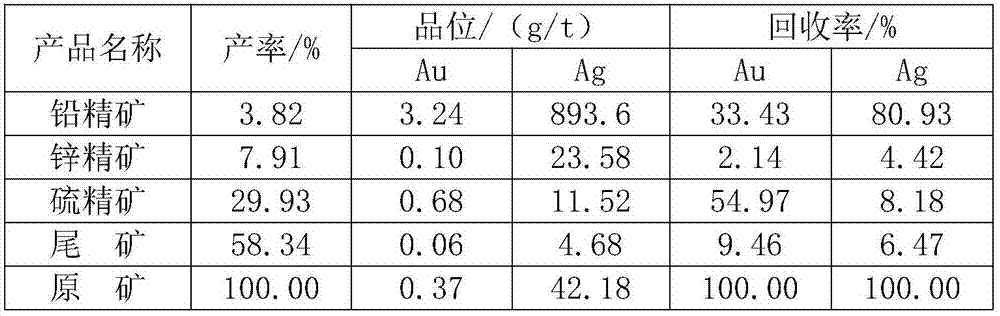

Examples

Embodiment 1

[0027] Embodiment 1, one, the preparation of efficient zinc-sulfur mineral inhibitor XKY012

[0028] Mix 100 grams of zinc sulfate, 50 grams of sodium sulfite, and 10 grams of hydroxyethyl cellulose, use a beaker as a container under normal pressure, use hot water above 60°C as a solvent, and stir with a magnetic stirrer for 20 to 30 minutes to obtain XKY012 solution.

[0029] 2. Preparation of high-efficiency lead, gold and silver mineral collection foaming agent XK712

[0030](1) With 100 grams of anhydrous sodium carbonate, 1000 grams of clear water, under normal temperature and pressure, use a beaker as a container, and stir with a magnetic stirrer for 5 to 10 minutes to obtain a 10% concentration sodium carbonate solution.

[0031] (2), 40 grams of dihydrocarbyl dithiophosphate, 30 grams of dianilino ammonium dithiophosphate, 20 grams of sodium diethyldithiocarbamate, and 10 grams of isoamyl xanthate were mixed, and the A beaker is used as a container, the above-mentione...

Embodiment 2

[0050] Embodiment 2, one, the preparation of efficient zinc-sulfur mineral inhibitor XKY012

[0051] Mix 50 grams of zinc sulfate, 50 grams of sodium sulfite, and 10 grams of hydroxyethyl cellulose, use a beaker as a container at normal temperature and pressure, use hot water above 60°C as a solvent, and stir with a magnetic stirrer for 20 to 30 minutes to obtain XKY012 solution.

[0052] 2. Preparation of high-efficiency lead, gold and silver mineral collection foaming agent XK712

[0053] (1) With 100 grams of anhydrous sodium carbonate, 1000 grams of clear water, under normal temperature and pressure, use a beaker as a container, and stir with a magnetic stirrer for 5 to 10 minutes to obtain a 10% concentration sodium carbonate solution.

[0054] (2), 40 grams of dihydrocarbyl dithiophosphate, 30 grams of dianilino ammonium dithiophosphate, 20 grams of sodium diethyldithiocarbamate, and 10 grams of isoamyl xanthate were mixed, and the A beaker is used as a container, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com