Method for increasing fine-grained wolframite ore dressing recovery ratio

A fine-grained, recovery rate technology, used in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc., can solve the problems of high pharmaceutical cost, high tungsten grade, and high water pressure requirements. Improve the recovery rate of beneficiation, simplify the process flow, and ensure the effect of the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

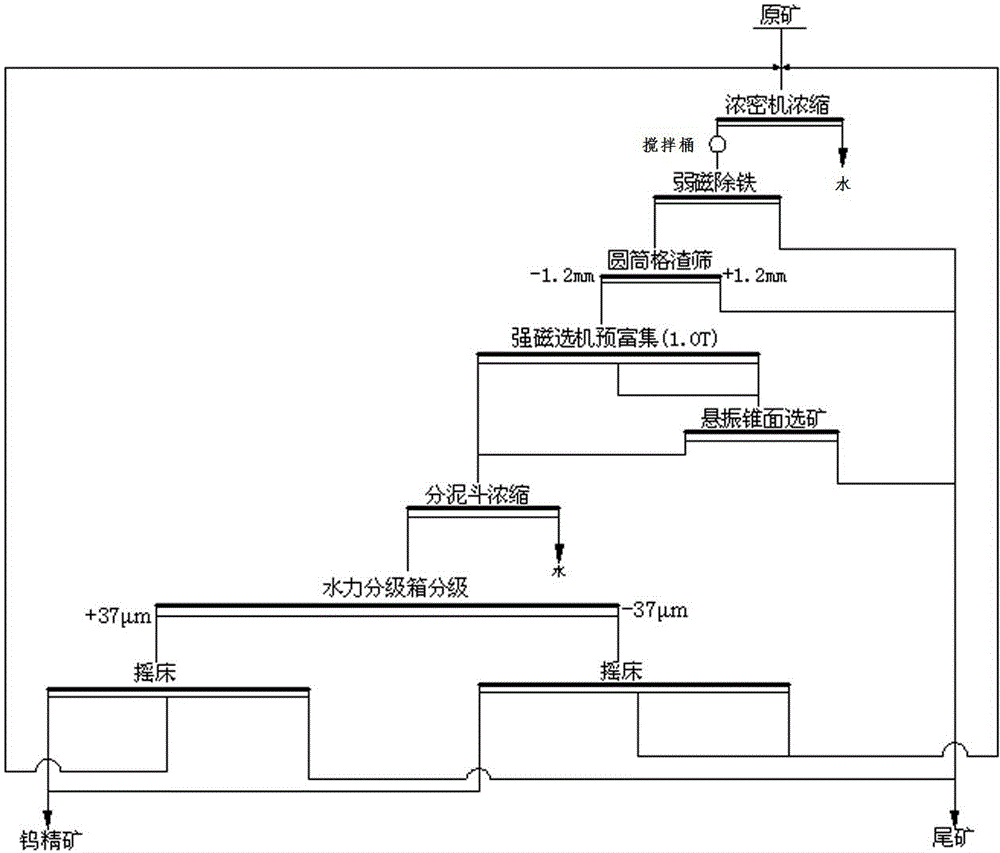

[0023] The raw ore is tungsten slime from a black tungsten beneficiation plant in Hunan, and the recyclable valuable mineral is black tungsten ore, WO 3 The grade is 0.59%. The original process directly uses a single shaker for gravity recovery, which occupies a large area and the recovery rate is low, only 40-50%. The present invention adopts strong magnetic pre-enrichment for this mine, and the suspended vibrating cone concentrator further enriches the tungsten in the strong magnetic tailings, and then classifies and recycles the tungsten in the shaking table. This process provides a new process for improving the recovery rate of tungsten fine sludge in black tungsten beneficiation plant. The chemical multi-element analysis of tungsten slime is shown in Table 1.

[0024] Table 1 Chemical multi-element analysis of raw ore

[0025] element WO 3 Al 3 o 2 SiO 2 CaO MgO K 2 o CaF 2 Fe content / % 0.59 6.50 76.01 2.51 1.29 1.22 2.67 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com