Flotation machine for fluorite and lead-zinc ore

A lead-zinc ore and flotation machine technology, applied in flotation, solid separation and other directions, to avoid sinking, avoid wear, and stabilize production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

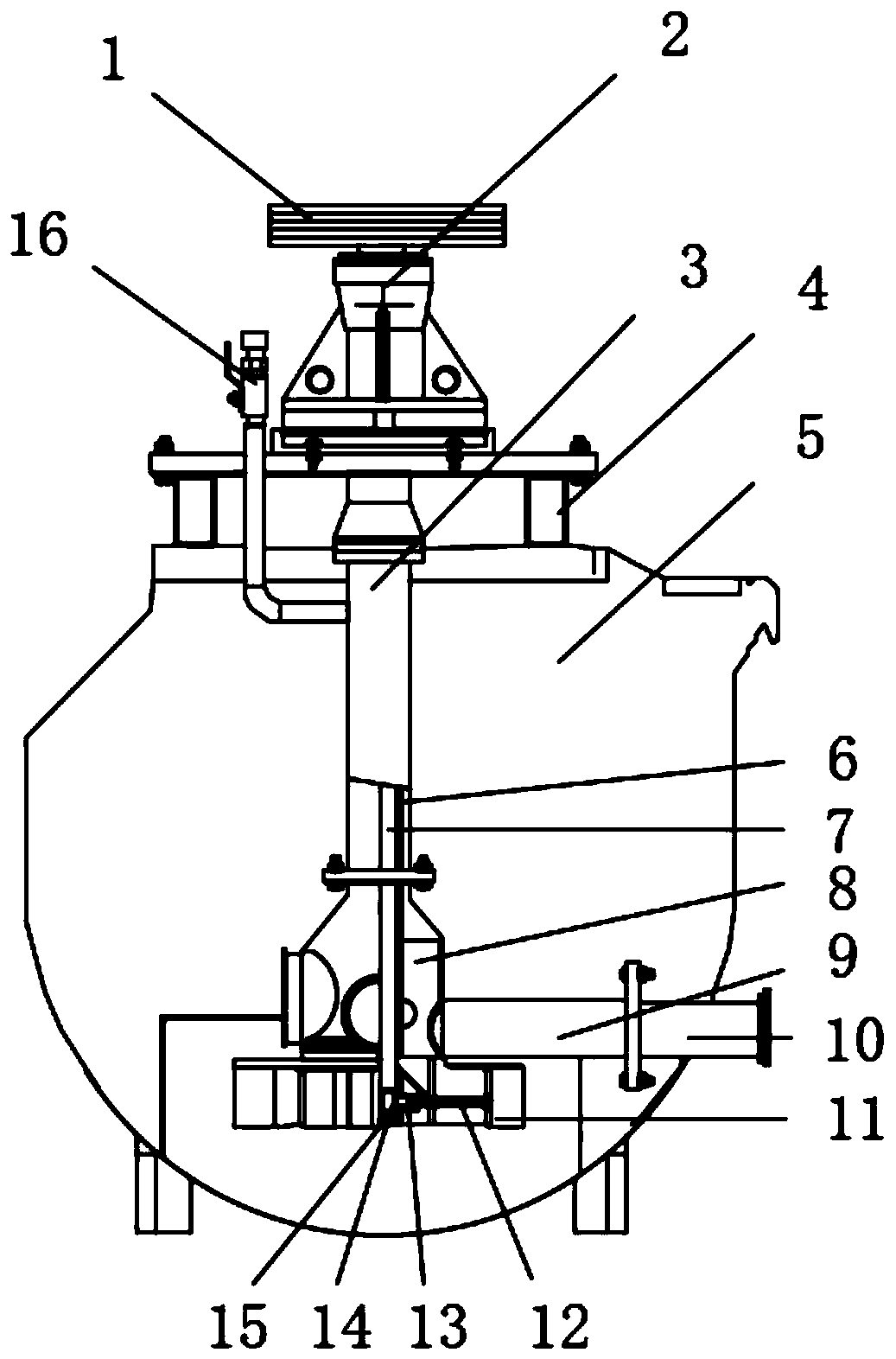

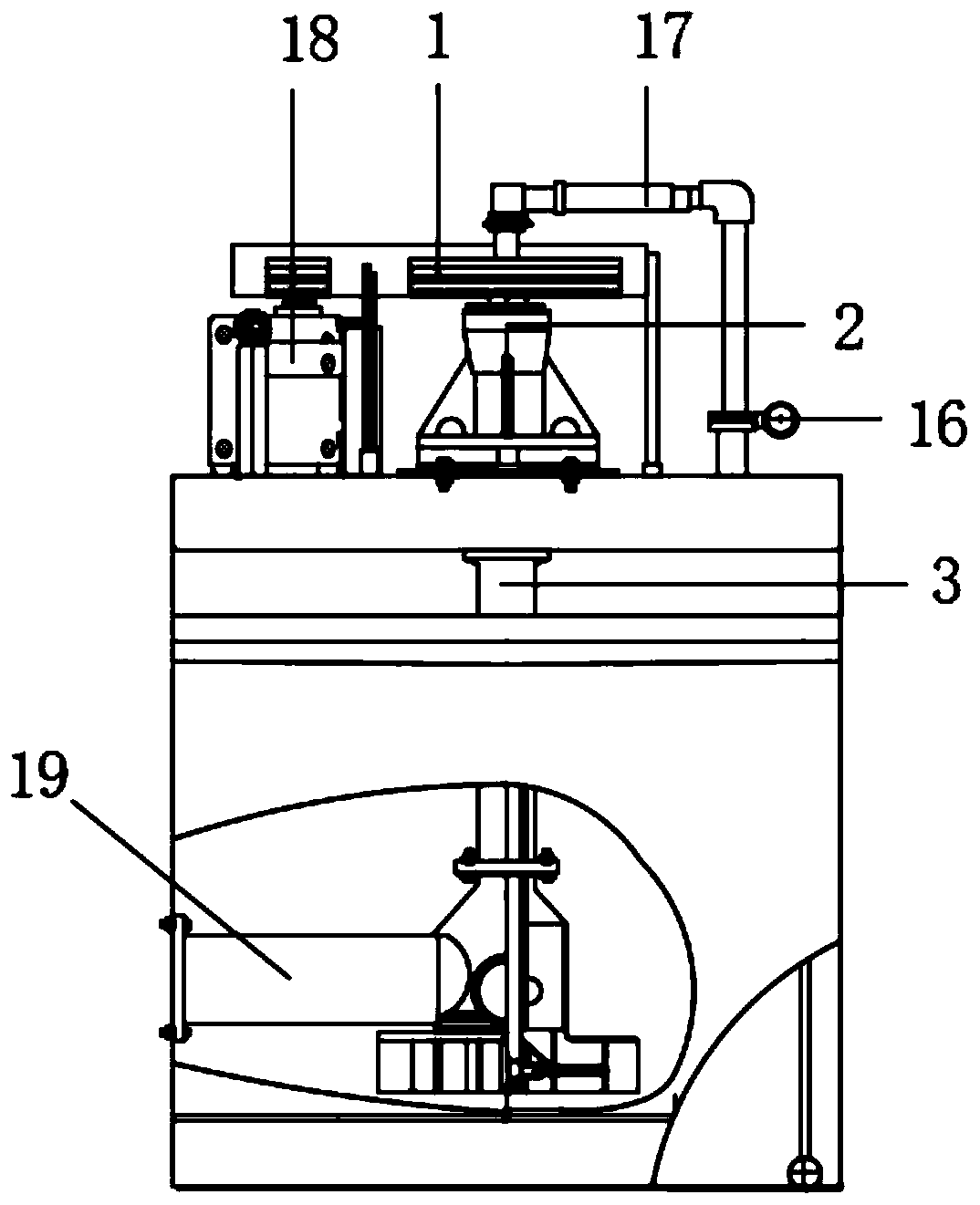

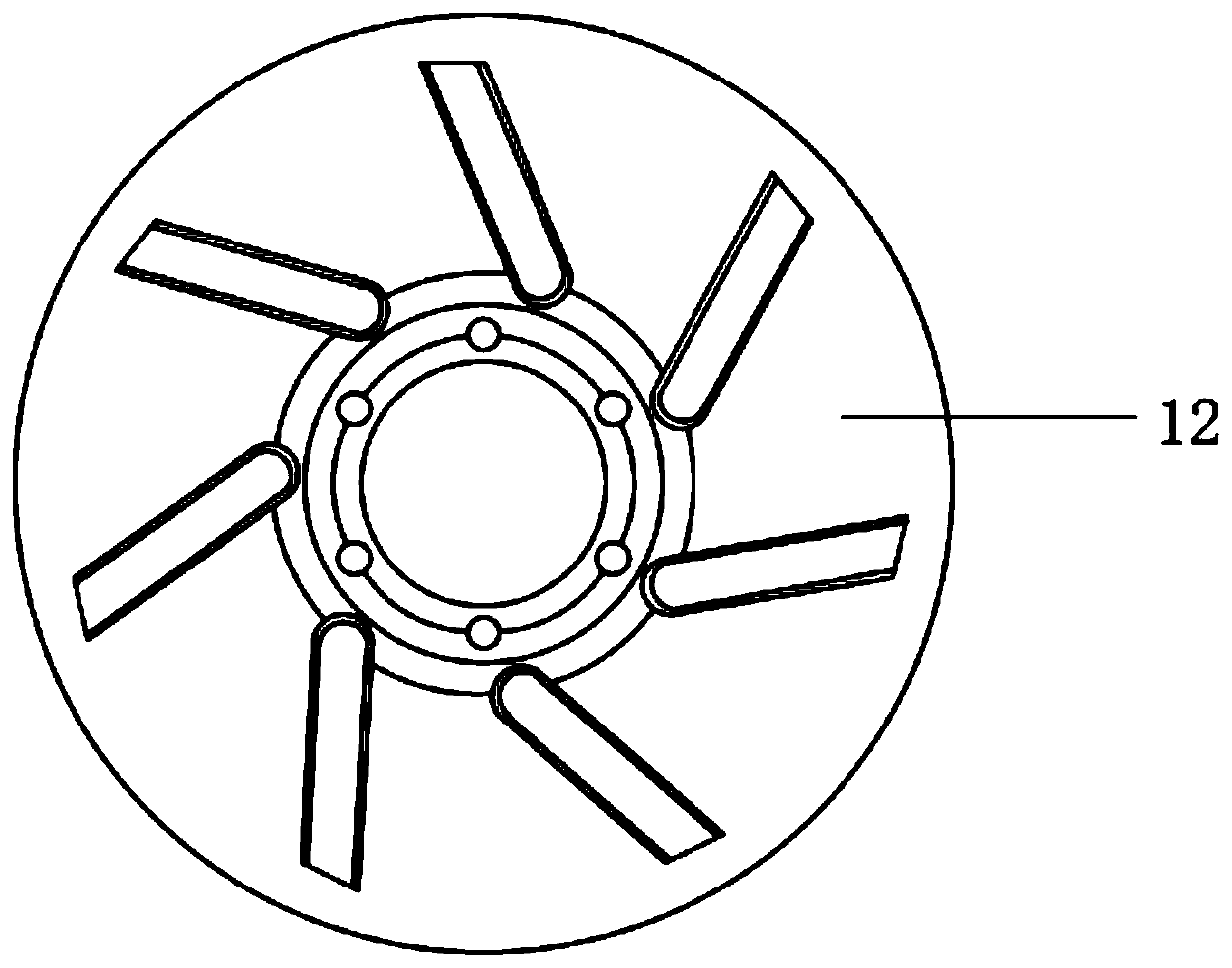

[0027] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a special flotation machine for fluorite and lead-zinc ore, including a tank body 5, the tank body 5 adopts a U-shaped design, and a bearing body is arranged in the middle of the upper end of the tank body 5 2. The lower end of the bearing body 2 is fixedly connected with a connecting pipe 3, the lower end of the connecting pipe 3 is fixedly connected with a central cylinder 8, the bearing body 2 is connected with the central cylinder 8 through the connecting pipe 3, and the lower end of the central cylinder 8 A cover plate 11 is fixedly connected, and the cover plate 11 is located in the tank body 5, and a self-suction device 16 is connected to the outside of the upper end of the connecting pipe 3, and the self-suction device 16 passes through the connecting pipe 3 and the central cylinder 8. The cover plate 11, the central cylinder 8 and the connecting pipe 3 are intersper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com