Method for synthesizing N,N-diethylamino ethanethiol

A technology of diethylaminoethanethiol and ethylaminoethanethiol, which is applied in the field of N, can solve the problems of high recovery energy consumption, low yield, poor product quality, etc., achieve environmental protection, high yield, and prevent self-polymerization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In a 500-liter reactor, 60 kilograms of ethylene sulfide were first added and stirred, then 180 kilograms of diethylamine were added, and 2 kilograms of petroleum ether were added, followed by stirring, and the temperature was refluxed at 60°C. After the reaction was completed for 10 hours, diethylamine and petroleum ether were recovered by distillation, and then 107 kg of N,N-diethylaminoethanethiol was obtained by distillation under reduced pressure.

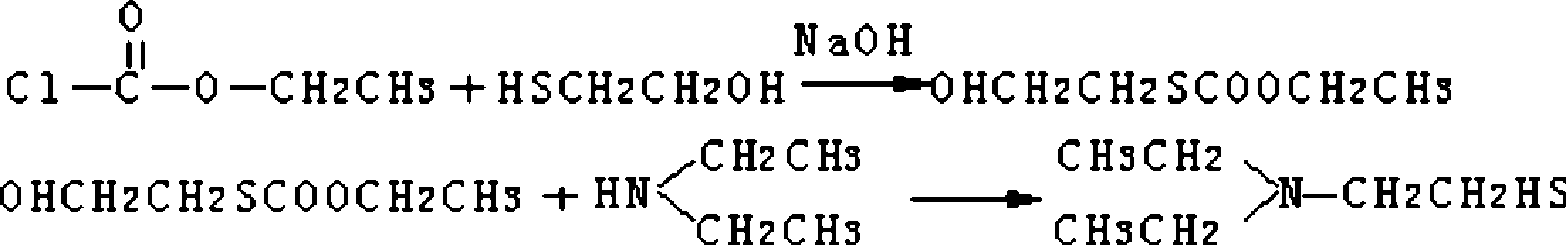

[0042] The reaction equation of the present embodiment is:

[0043]

[0044] The mass percentage concentration of N,N-diethylaminoethanethiol in this embodiment is 99%, and the yield can reach 95.5%.

Embodiment 2

[0046] In a 2000-liter reactor, 240 kilograms of ethylene sulfide were first added and stirred, then 1200 kilograms of diethylamine were added, and 4 kilograms of sodium borohydride were added, followed by stirring and heating at 55°C. Reflux reaction for 15 hours, after the reaction is completed, diethylamine and sodium borohydride are recovered by distillation, and then 435 kg of N,N diethylaminoethanethiol can be obtained by distillation under reduced pressure.

[0047] The mass percentage concentration of N,N diethylaminoethanethiol in this embodiment is 99%, and the yield can reach 96.4%.

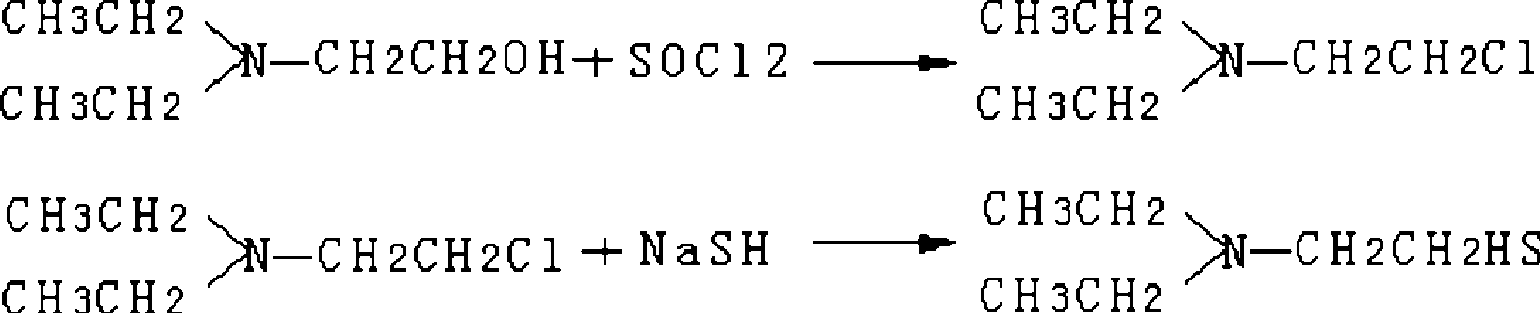

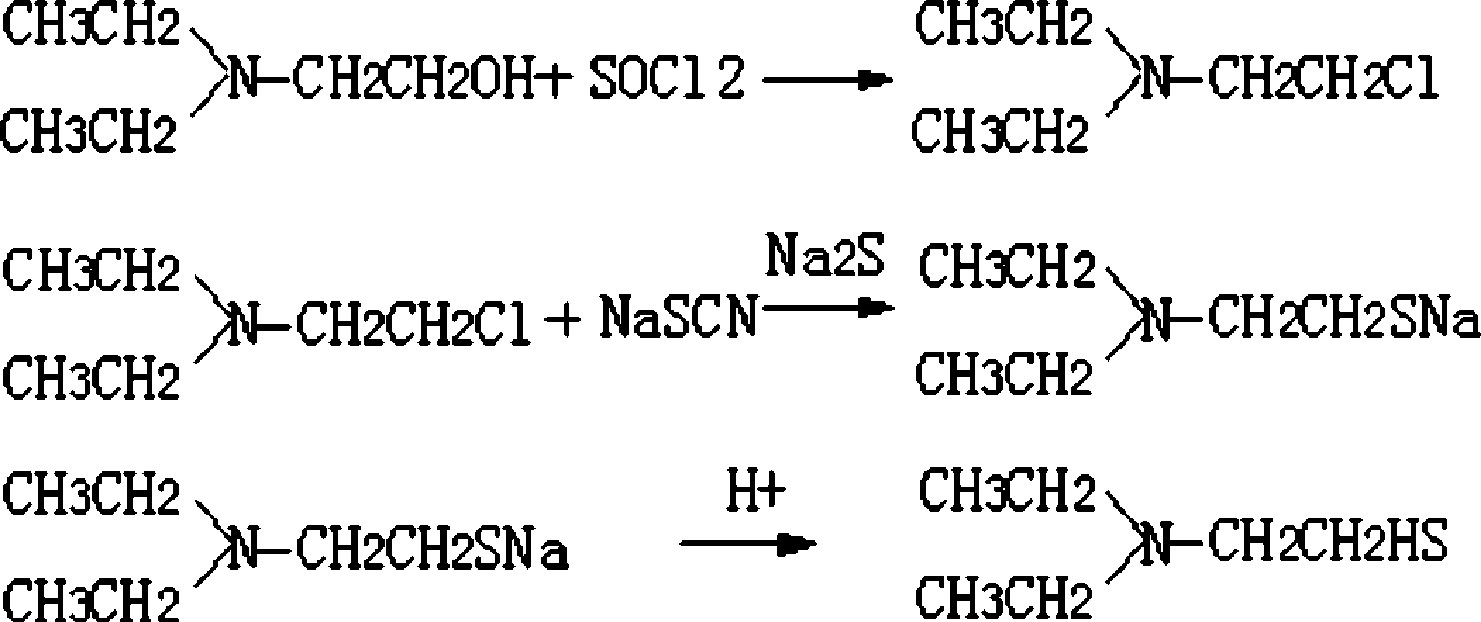

[0048] The reaction equation of the present embodiment is:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com