System and method for continuously synthesizing clethodim

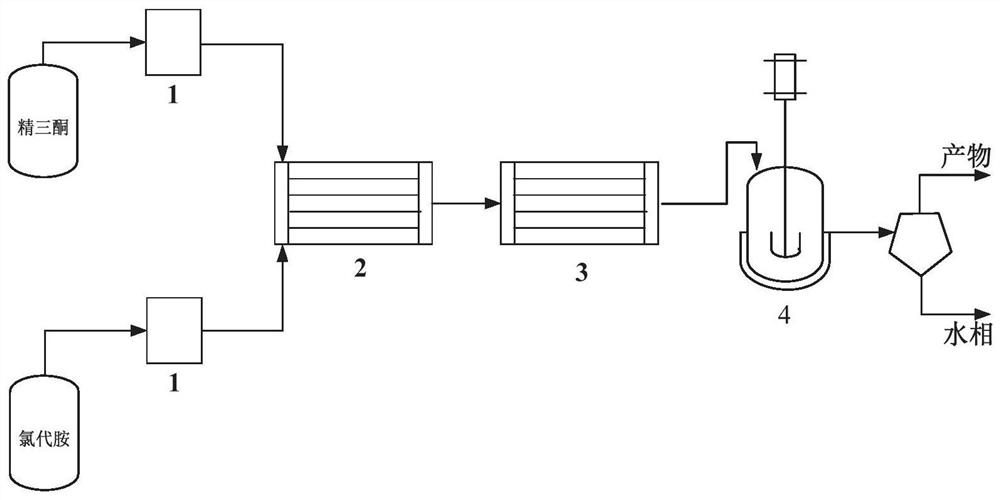

A technology of clethodim and microchannel reactor, which is applied in chemical instruments and methods, thioether preparation, chemical/physical/physicochemical processes, etc. It can solve the problems of long reaction time, low content of clethodim, low yield, etc. problems, to achieve safe preparation, increase the reaction speed, and the effect of continuous preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

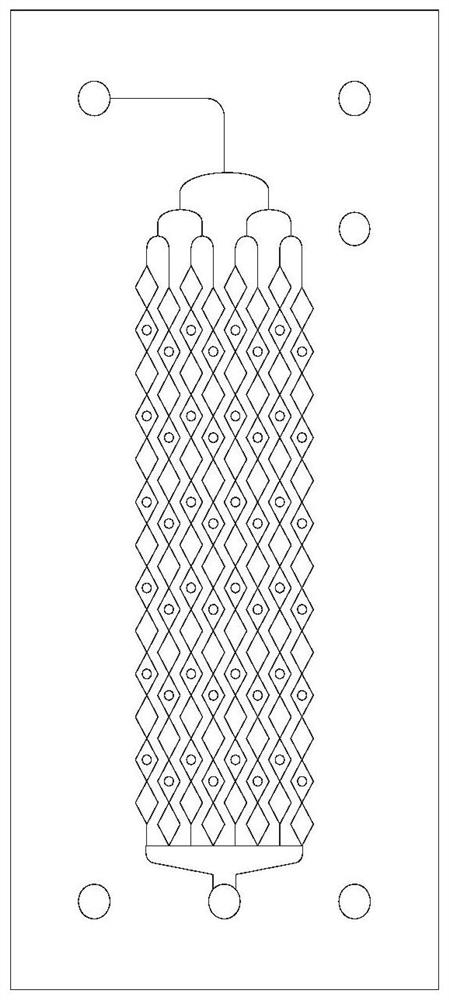

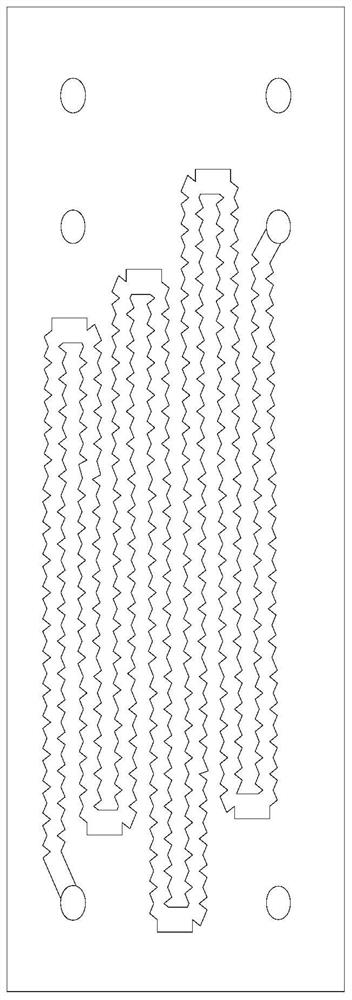

[0043]Chloramine (purity: 93.8%) and triketone (purity: 94.0%) are used as raw materials, and ethanol is used as a solvent. Firstly, triketone is dissolved in ethanol to prepare a triketone ethanol solution with a content of triketone of 50 wt%. Chloramine and refined triketone ethanol solution are pumped feed with flow rate 4ml / min and 20ml / min respectively, and feed time is 5min, and feed amount is respectively: chloramine 21.9g (0.19mol), refined triketone ethanol solution 91.8g (0.16mol), the feed molar ratio of chlorinated amine and fine triketone is 1.19. The two raw materials are strongly mixed and reacted in parallel microchannel reactor I with channel hydraulic diameter of 0.5mm and liquid holding volume of 7.2ml; the reaction materials are further mixed and reacted in microchannel reactor II, and the reaction materials are mixed and reacted in two reaction The total residence time in the device was 43 seconds. At the same time, control the reaction temperature of m...

Embodiment 2-4

[0046] Using the same continuous synthesis system of clethodim as in Example 1, the ethanol solution was obtained by dissolving the triketone in ethanol, and the content of the triketone in the ethanol solution was 50 wt%. Difference with embodiment 1 is: chlorinated amine and refined triketone mol ratio are 1.15, refined triketone flow rate 40ml / min, chlorinated amine flow rate is 8ml / min, the total amount of material in microchannel reactor I and II The reaction residence time was 22 seconds. During the reaction, the reaction temperatures of microchannel reactors I and II were the same. In Examples 2-4, the reaction temperatures were controlled to be 55° C., 65° C., and 70° C. respectively. The product results are shown in Table 1, respectively.

[0047] Table 1, the influence of different temperatures on the reaction

[0048]

[0049] As can be seen from the data in the above table, increasing the reaction temperature will speed up the mixing and mass transfer rate betw...

Embodiment 5-7

[0051] The same system for continuous synthesis of clethodim as in Example 1 was used. The difference with Example 1 is as follows: in the reaction process, the reaction temperature of the reaction material in the microchannel reactor I and II is 75°C, the refined triketone flow rate is 40ml / min, and the chloramine flow rate is 6.5~8ml / min, The residence time is 22 seconds, and the molar ratios of chlorinated amines and refined triketones in the feed are controlled to be 1.10, 1.15, and 1.20, respectively. The product results are shown in Table 2.

[0052] Table 2, the influence of chlorinated amine and fine triketone molar ratio on reaction

[0053]

[0054] As can be seen from the data in the table above, increasing the molar ratio of chlorinated amines and refined triketones, that is, increasing the amount of chlorinated amines, the conversion rate of refined triketones and the yield of clethodim also increase accordingly, and increasing the amount of chlorinated amines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com