Polyvinyl acetate with low polymerization degree and polymerization method thereof

A technology of polyvinyl acetate and low polymerization degree, which is applied in the field of polymer and its preparation, and can solve the problems of no PVAC and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

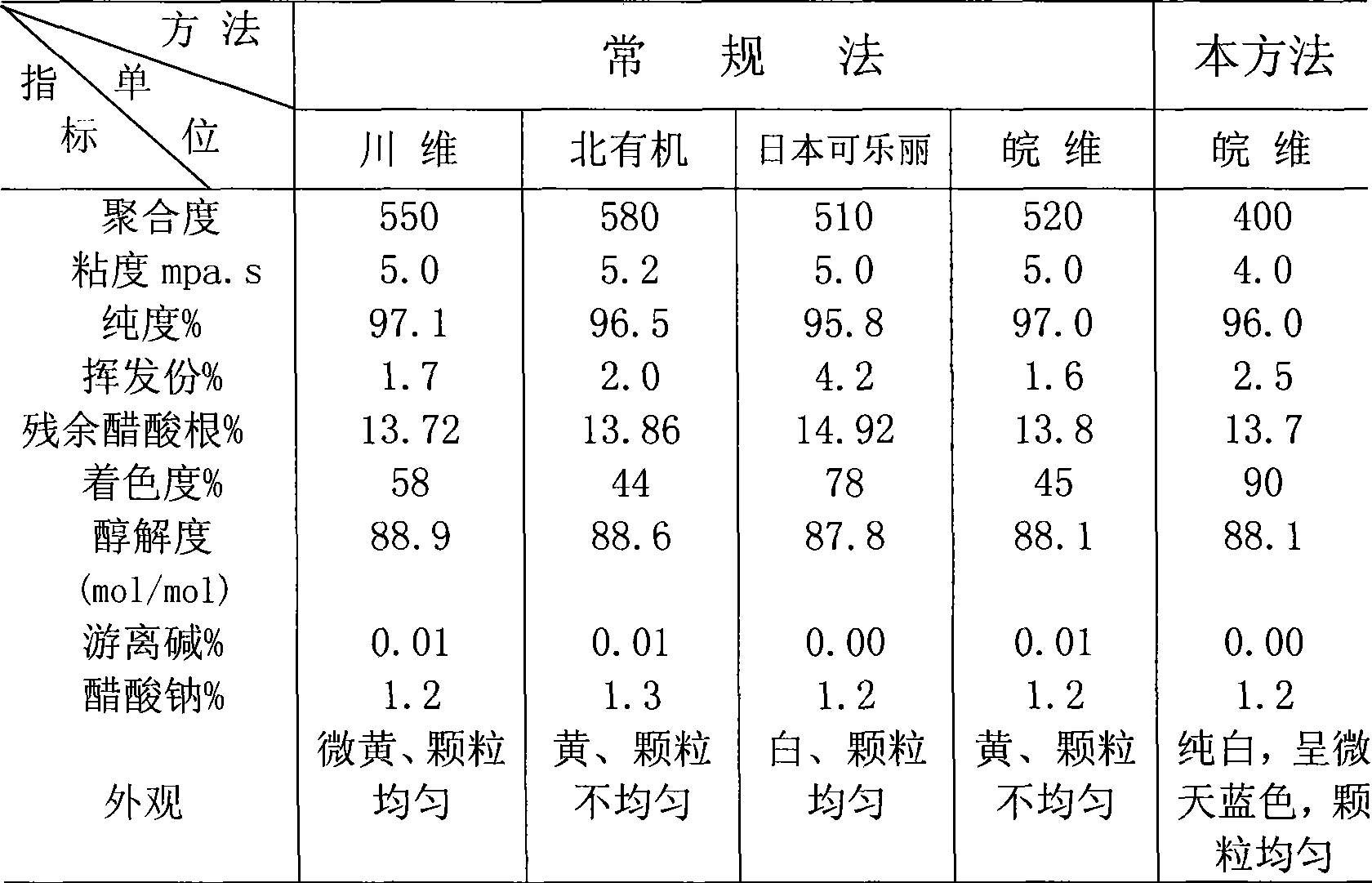

[0017] Now take the PVAC of processing PA=400±50 as an example, and the non-limiting embodiment is described as follows:

[0018] 1. Ingredients

[0019] Take VAC 1000L (approximately 930kg) with a purity of 99.3%, add 200L of methanol and put it into a polymerization kettle equipped with a stirrer and a reflux condenser.

[0020] Take 0.47kg of initiator AIBN (0.05% of VAC) to prepare a methanol solution with a concentration of 1.0-1.5%.

[0021] Take 3.7kg of methyl mercaptan and make it into a methanol solution with a concentration of 10-12%.

[0022] 2. Polymerization

[0023] When the monomer is preheated to 59°C, add the methanol solution of initiator and chain transfer agent, polymerize at 65°C for 2.5 hours, stir at a speed of 7-8 rpm, then reduce the speed to 5-6 rpm to continue polymerization 2.5 hours.

[0024] 3. Separation

[0025] After the polymerization reaction is completed, it is transferred to a still, and methanol vapor is blown from the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com