Rolling brush and dust collector with rolling brush

A vacuum cleaner and rolling brush technology, applied in the direction of the suction nozzle, can solve the problem of not being able to clean large particles of dust conveniently, and achieve the effects of convenient dust collection, reduced manufacturing costs, and material savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

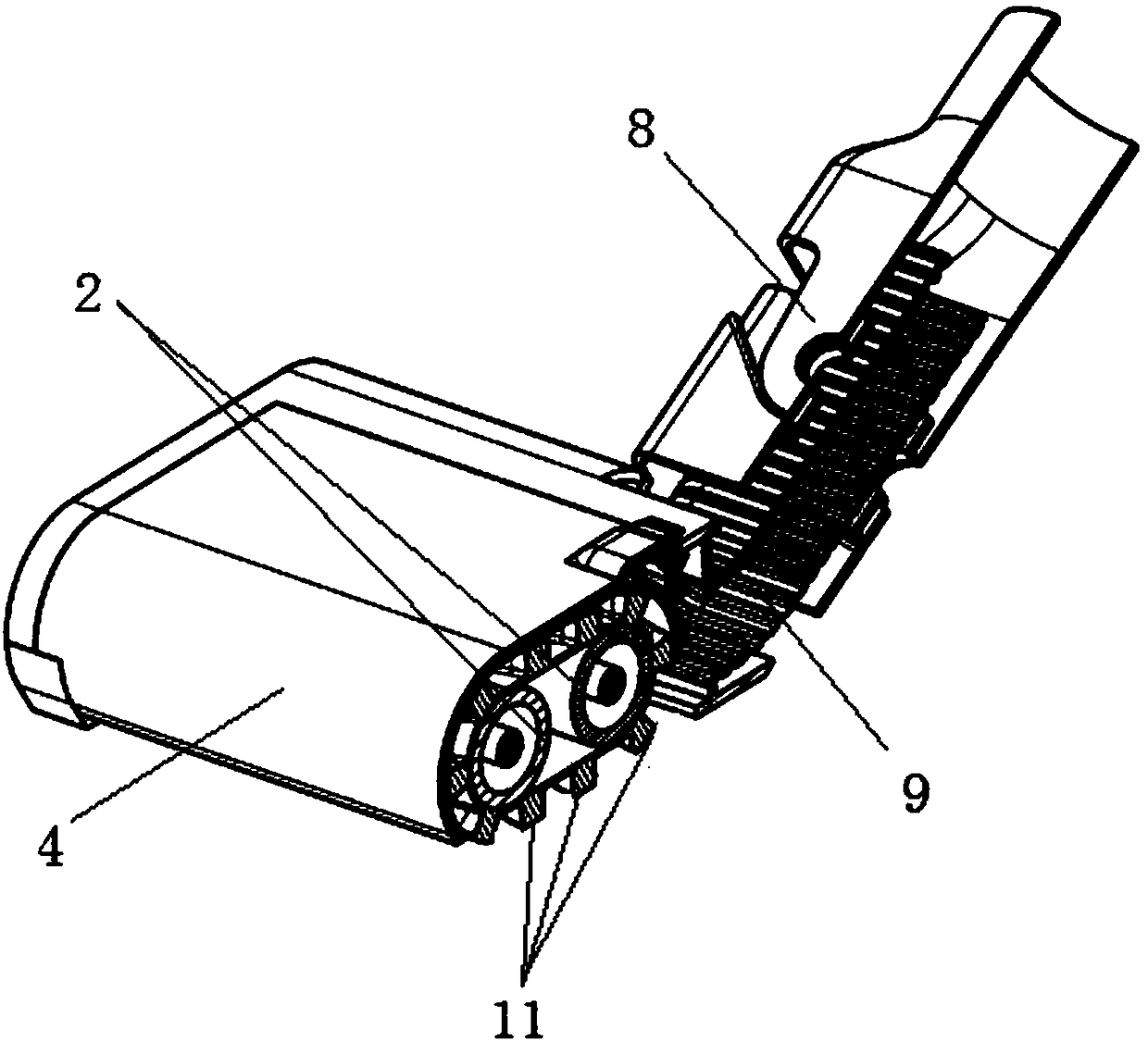

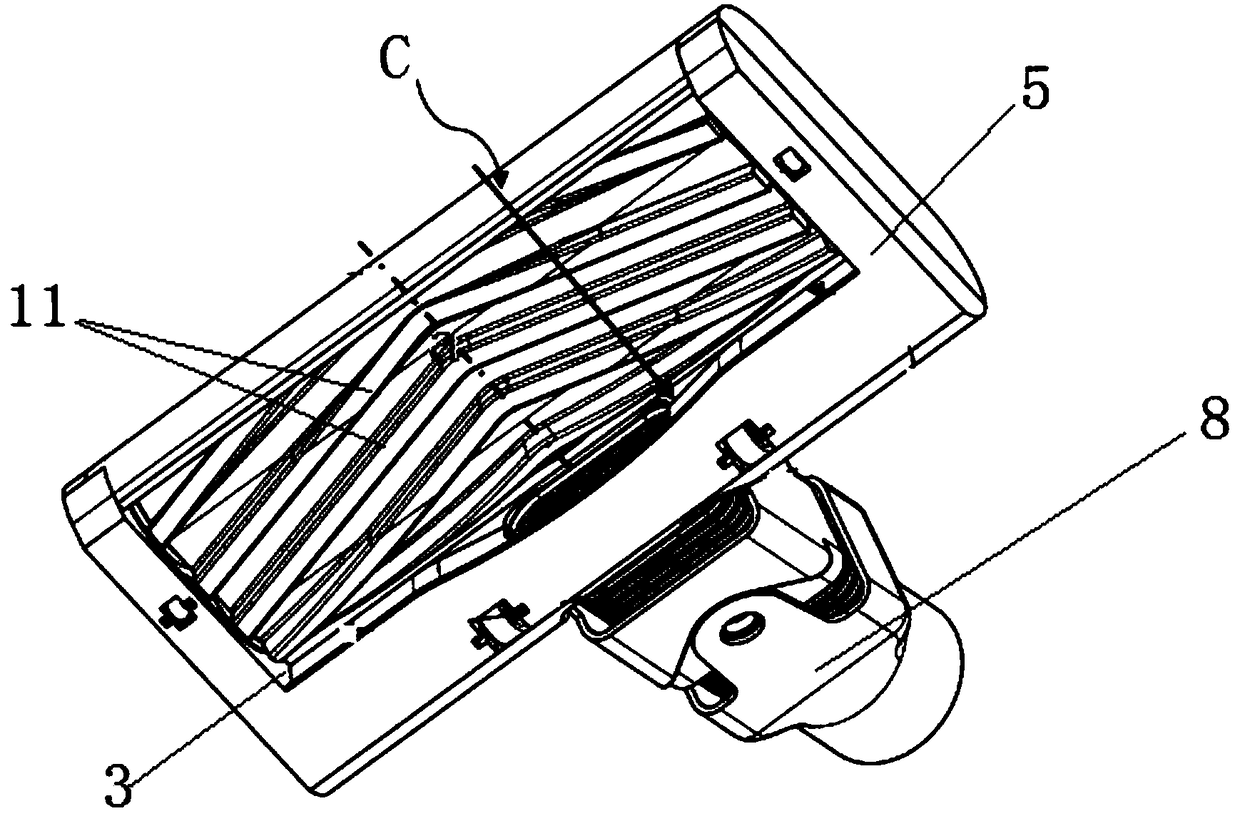

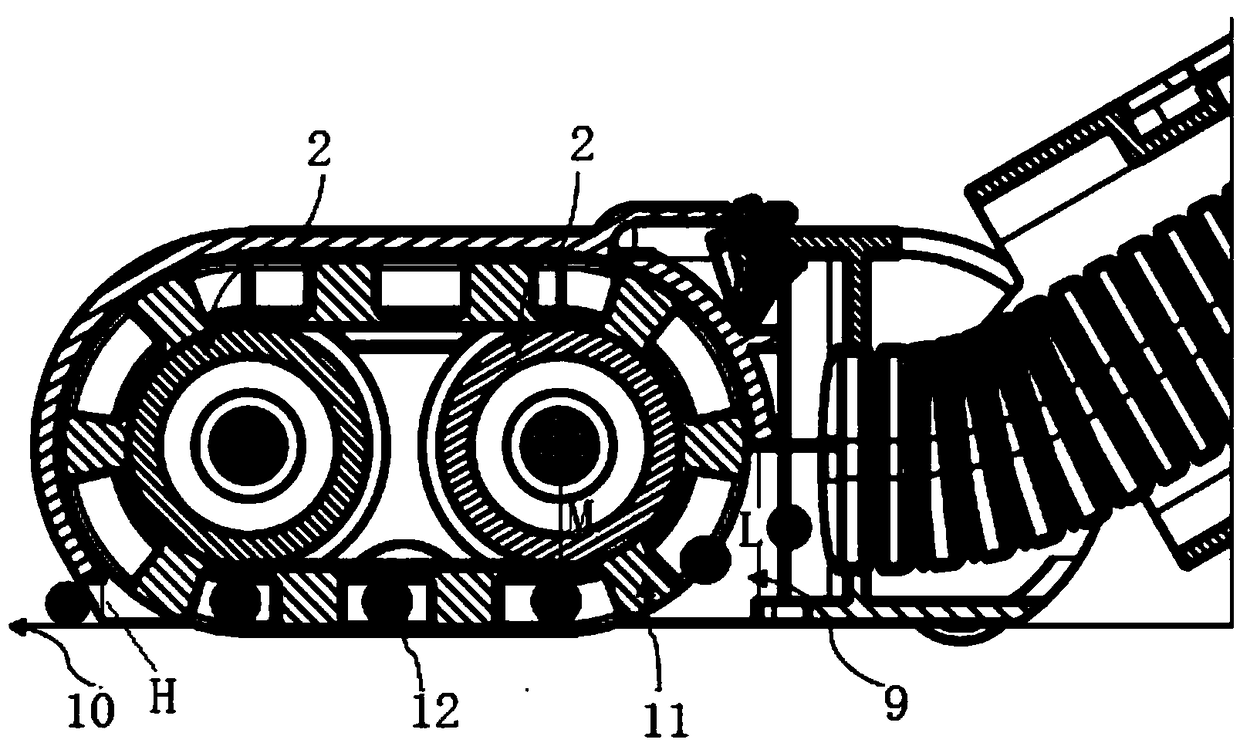

[0038] Such as Figure 1-5 Shown, a kind of roller brush of the present invention comprises:

[0039] Roller brush housing;

[0040] a drive assembly installed on the roller brush housing;

[0041] The rolling brush body 1 includes an annular belt body 7 installed on the drive assembly, and several raised brush strips 11 protruding from the outer surface of the annular belt body 7. The brush strips 11 are arranged at intervals, and the ring-shaped belt body 7 runs under the support and drive of the driving assembly, and keeps at least one raised brush strip 11 in contact with the surface to be cleaned 10 as a plane.

[0042] In the present invention, if image 3 As shown, gaps are formed between adjacent protruding brush strips 11, which not only saves the material for making the roller brush, reduces the manufacturing cost, but more importantly, in the cleaning process, the larger dust particles will be swept by the roller brush body. The raised brush strip 11 on 1 is tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com