Air conditioner having indoor unit with automatic air filter celaning function

An air filter and indoor unit technology, which is applied in air conditioning systems, dispersed particle filtration, household appliances, etc., can solve the problems of increasing power consumption, increasing the resistance of inhaled air ventilation, and increasing the depth of the main body, so as to achieve reliability Dust suction, small attraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

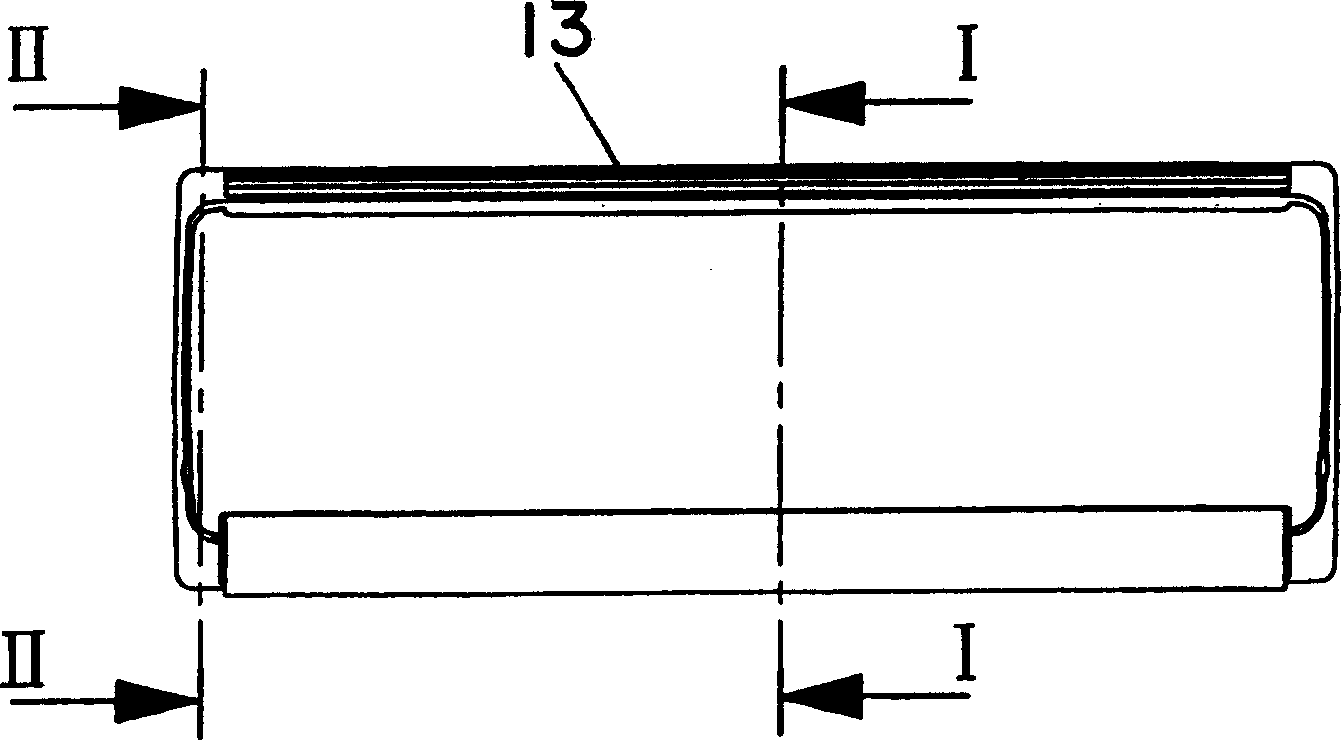

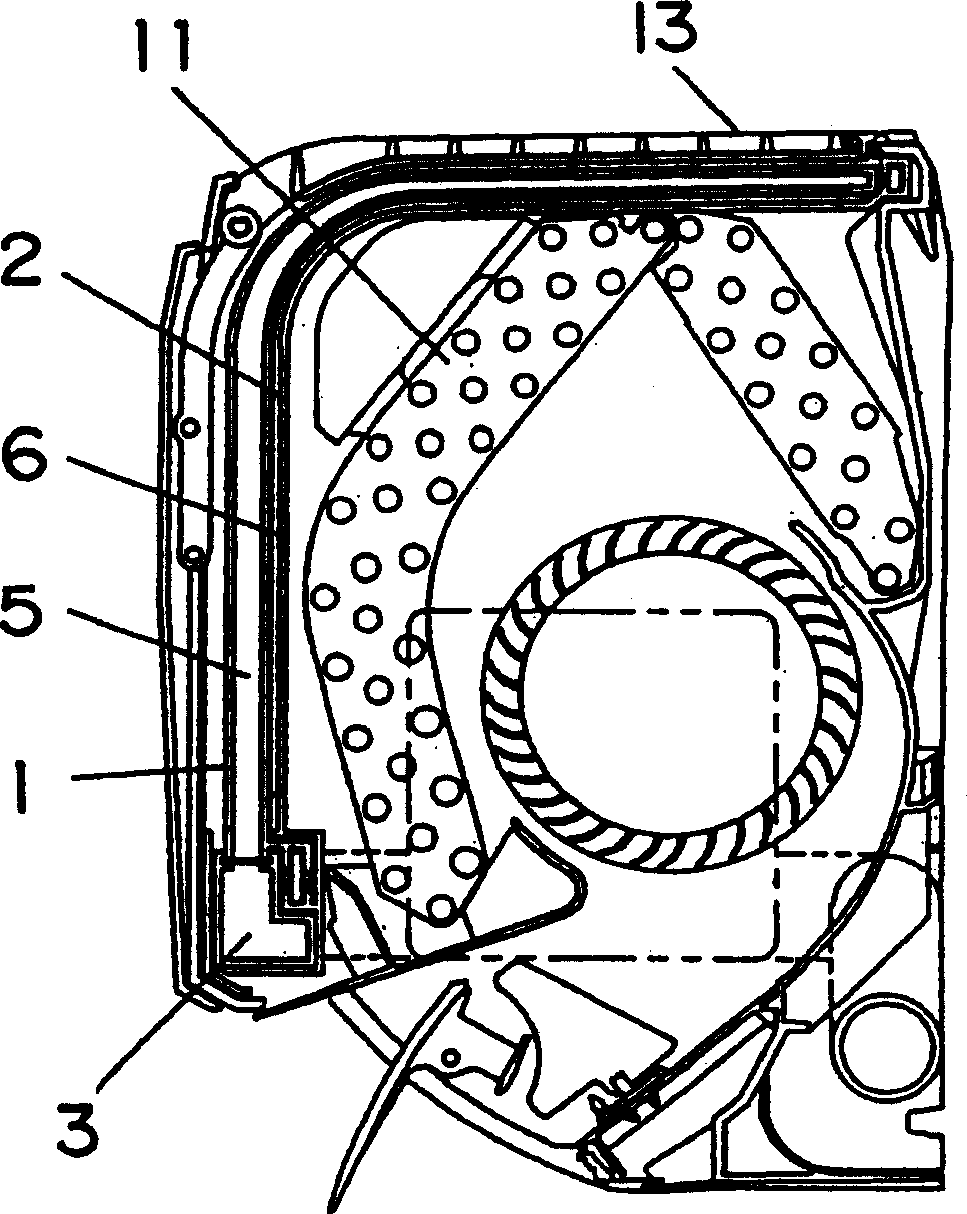

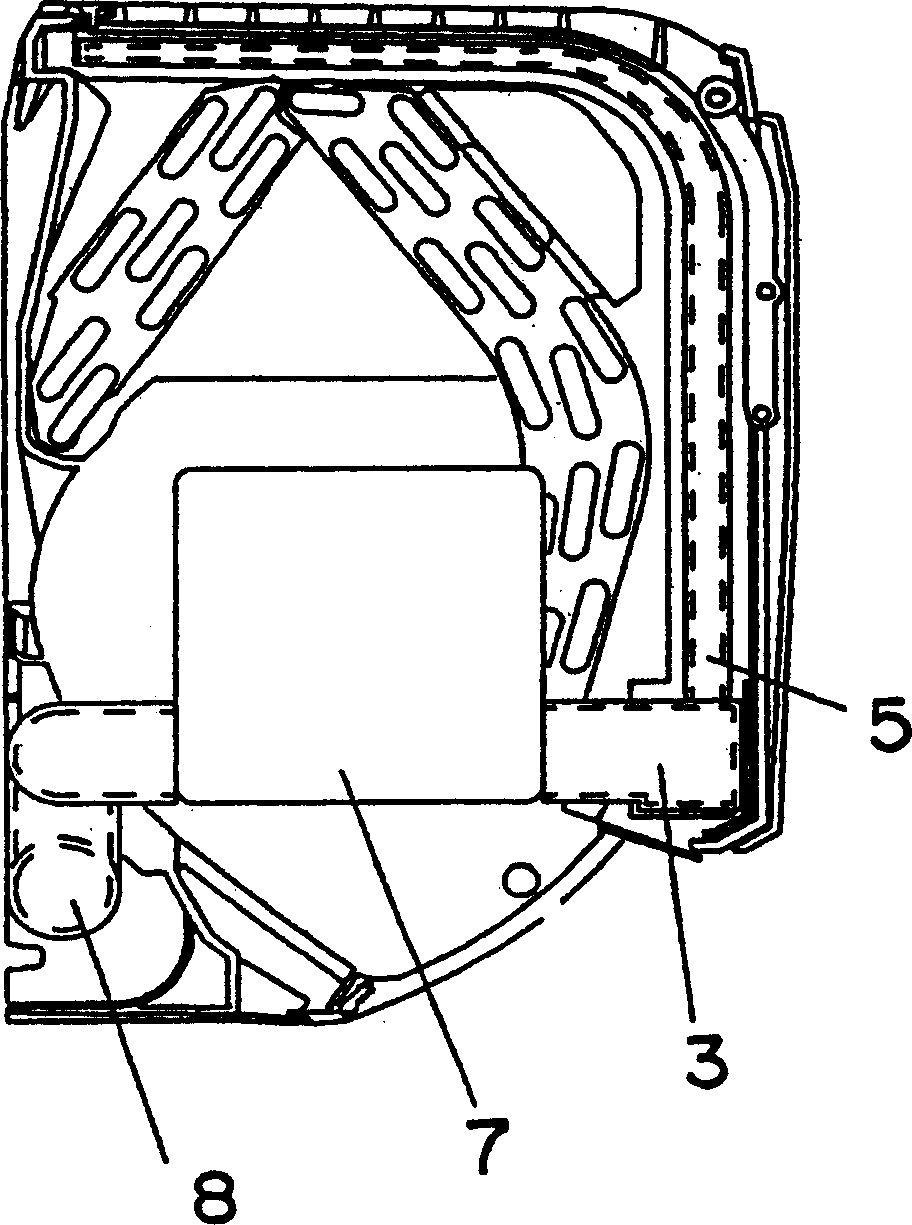

[0054] Figure 1 to Figure 3 An indoor unit showing an air conditioner according to Embodiment 1 of the present invention, figure 1 is the front view of the indoor unit, figure 2 as well as image 3 are along figure 1 Sectional views of line I-I and line II-II. and, Figure 4 as well as Figure 5 6A and 6B are a side view and a front view showing the appearance of a suction nozzle provided in the filter device.

[0055] In the inside of the indoor unit main body 13, there are housed: a heat exchanger 11; a fan 12 that sucks indoor air through the heat exchanger 11 and blows out air that has undergone heat exchange through the heat exchanger 11 to the room; The filter unit 1 on the upstream side of 11 sucks in air from a plurality of suction ports (not shown) formed by the operation of the fan 12, and the plurality of suction ports are formed from the front to the top of the main body 13, and are provided in the suction port and heat. Between the exchangers 11 the filte...

Embodiment approach 2

[0072] Figure 9 The filter device 1 shown in the indoor unit of the air conditioner according to Embodiment 2 of the present invention is different from the above-mentioned Embodiment 1 in that a vertically elongated baffle plate 14 is provided, and the elongated baffle plate 14 sandwiches Hold the air filter 6 and face the suction port 5a of the suction nozzle 5.

[0073] Such as Figure 10 as well as Figure 11 As shown, the upper and lower ends of the baffle 14 are respectively connected to the upper end 5 b and the lower end 5 c of the suction nozzle 5 , and are integrally formed with the suction nozzle 5 .

[0074] In this embodiment, by providing the shutter 14 at the position facing the nozzle suction port 5a on the inner surface side of the air filter 6, when the suction nozzle 5 moves in the left and right directions, the shutter 14 also moves together, and does not Since the remaining air is sucked from the suction port 5a, the dust adhering to the air filter 6 c...

Embodiment approach 3

[0080] Figure 14 to Figure 18 An indoor unit showing an air conditioner according to Embodiment 3 of the present invention, Figure 14 is the cross-sectional view of the indoor unit, Figure 15 It is a perspective view of the suction mechanism part of the filter device installed in the indoor unit, Figure 16 as well as Figure 17 is a partial sectional view of the suction mechanism seen from the back, Figure 18 It is an exploded perspective view of the suction nozzle.

[0081] Such as Figure 16 As shown, the suction duct 3 is formed in a cylindrical shape, and while one end is connected to a suction unit (not shown), the other end is closed. Openings 3 a are provided at equal intervals on the upper surface of the suction duct 3 , and opening and closing covers 16 are respectively attached to the openings 3 a. The opening and closing cover 16 normally closes the opening 3 a by a spring on the opening and closing cover 16 .

[0082] Through the fitting groove 5d, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com