Precision vacuum cleaner head

a vacuum cleaner and vacuum head technology, applied in the field of precision vacuum cleaners, can solve the problems of ineffective full cleaning, handheld vacuum units, lack of capacity to clean these areas, etc., and achieve the effect of efficient brushing and vacuuming soiled surfaces, compact design, and effective cleaning of flat and cornered soiled surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

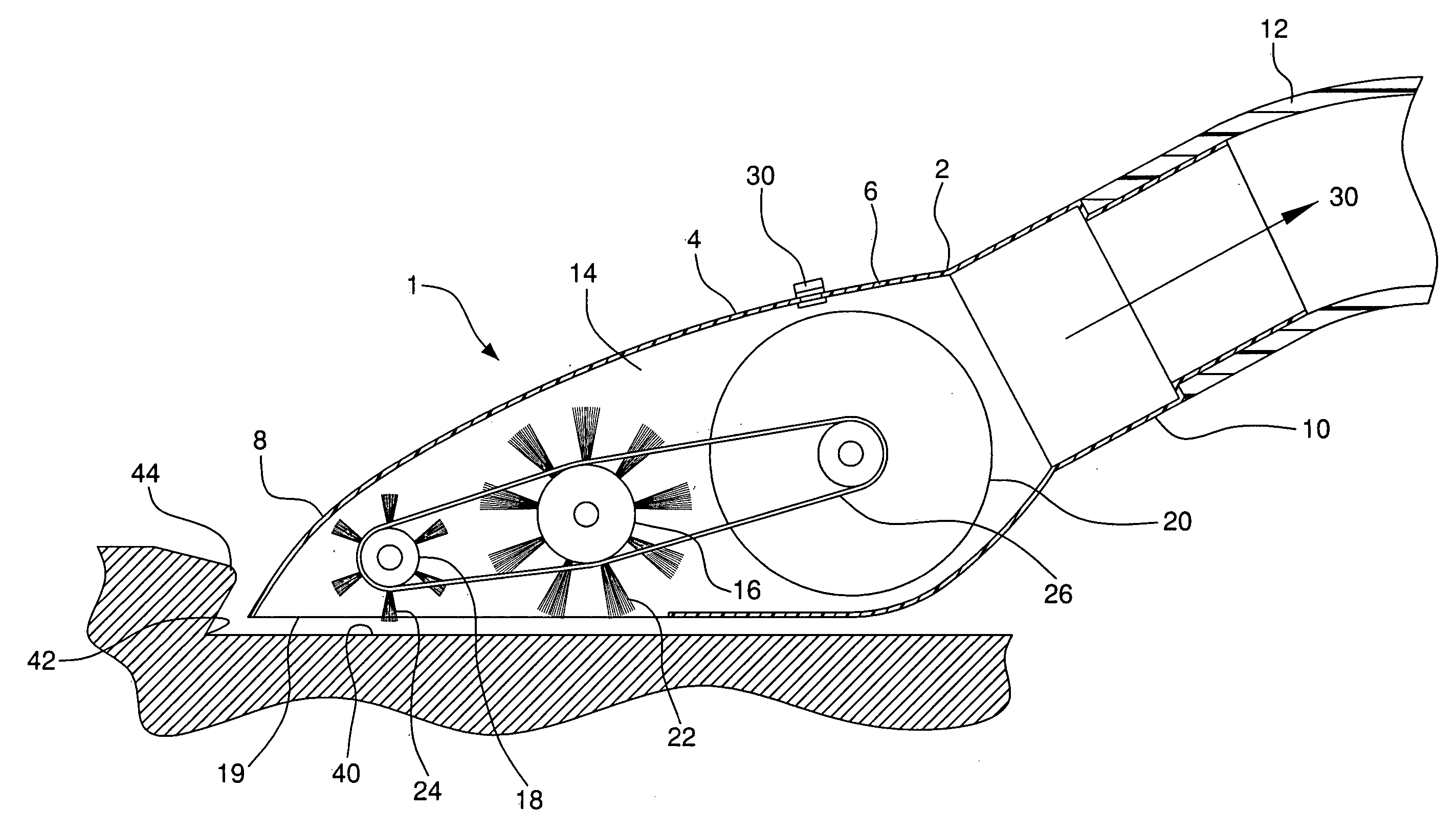

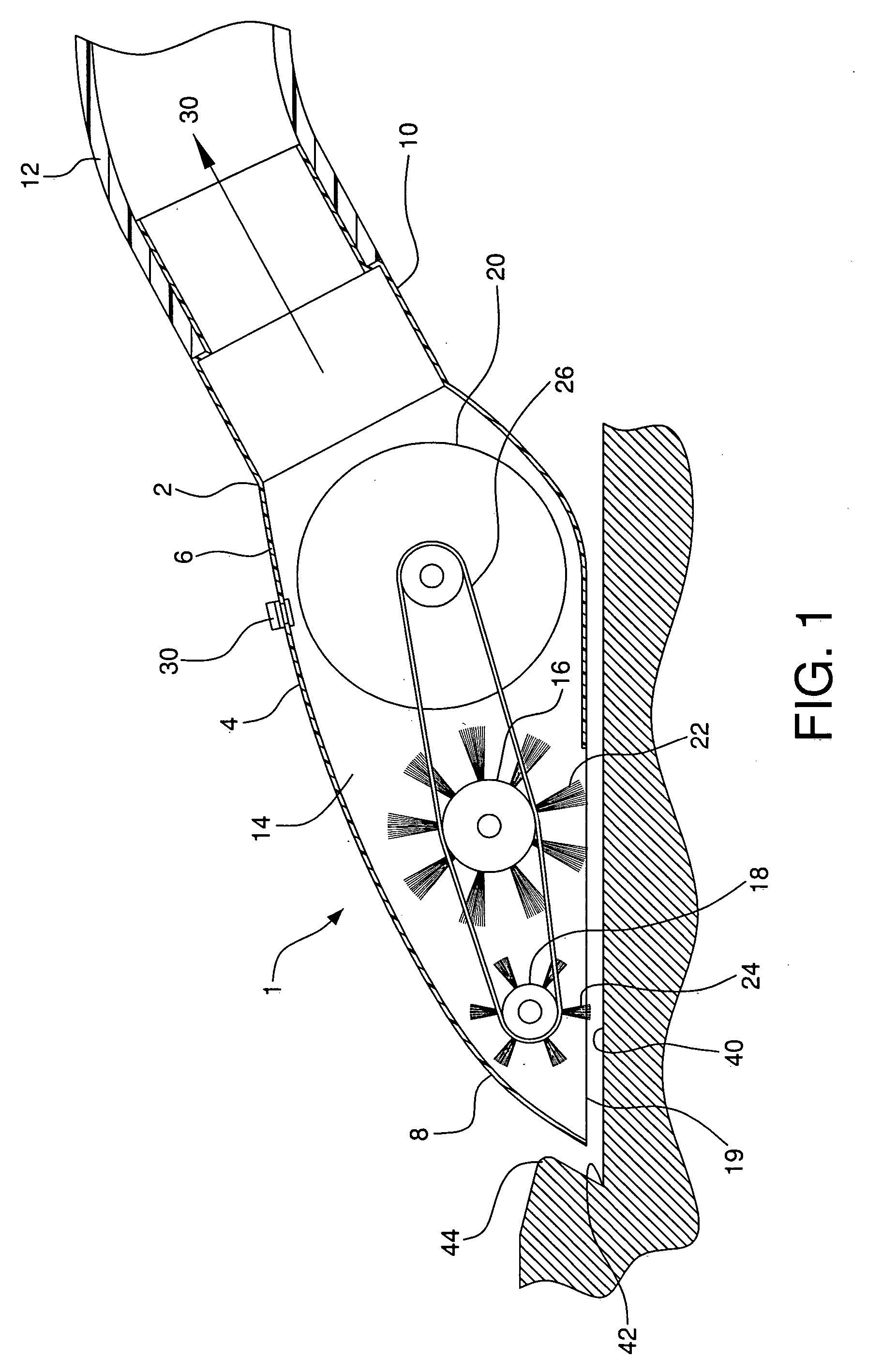

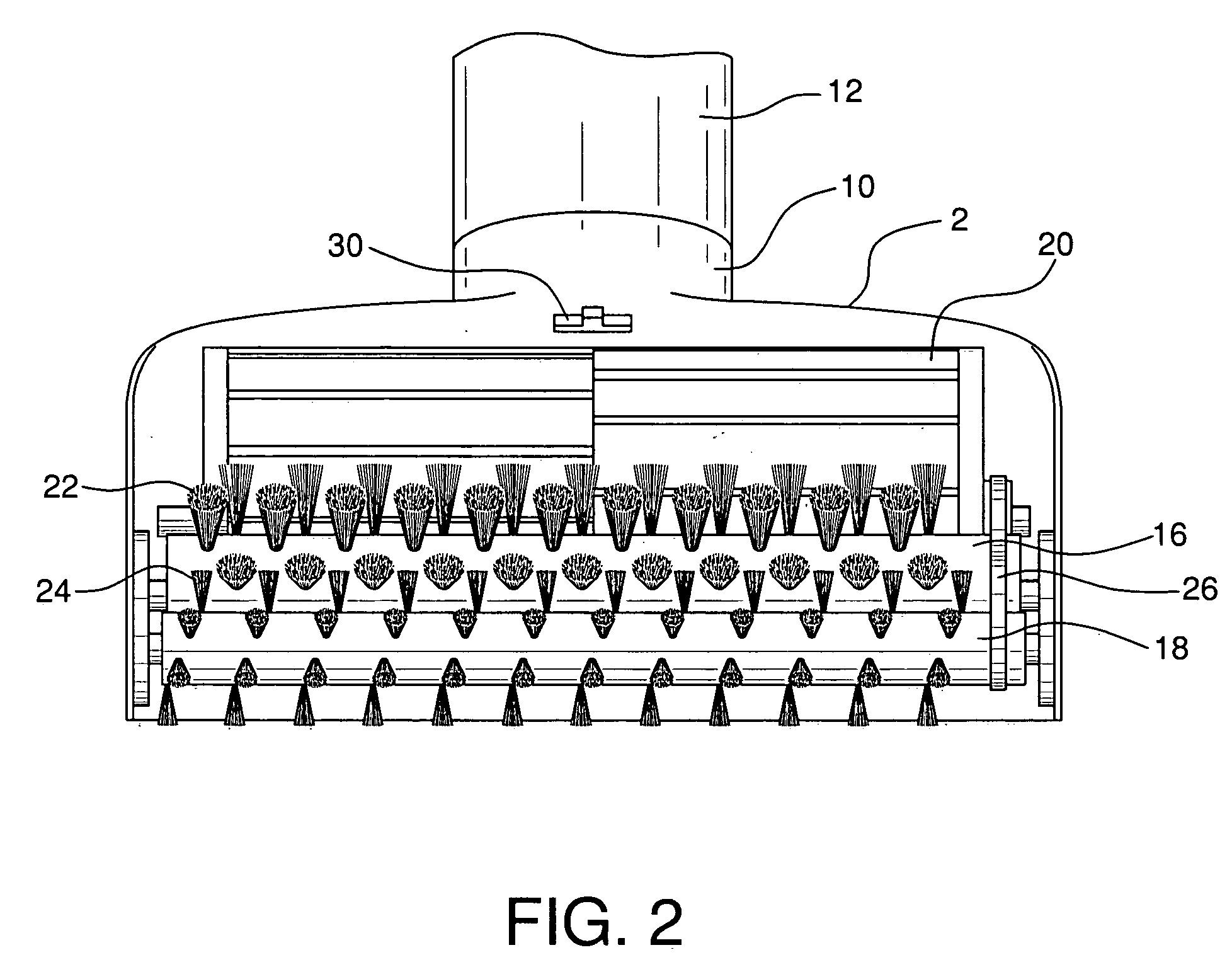

[0014] Precision vacuum cleaner head 1 of the present invention is configured to be used with a variety of vacuum cleaning units, and is especially adaptable for use with portable handheld cleaner units. Cleaner head 1 comprises housing 2 whose upper surface 4 is tapered gradually downward, from after section 6 to forward tapered section 8 of the housing. Housing 2 has extension section 10 which is configured for attachment to section connection line 12 which heads to the vacuum source of the cleaning unit.

[0015] Enclosed within housing 2 is substantially open chamber 14. Located within chamber 14 is first cylindrical rotary brush member 16, second cylindrical rotary brush member 18, and turbo drive wheel 20. First brush member 16 is larger in diameter than second brush member 18. First brush member 16 also has longer bristles 22 than second brush member 18, whose bristles 24 may also be finer than bristles 22. Suction opening 19 at the bottom of housing 2 allows bristles 22 and 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com