Method for making an improved aluminum alloy sheet product

a technology of aluminum alloy sheet and product, which is applied in the field of aluminum alloy sheet and methods for making aluminum alloy sheet, can solve the problems of pressure welding and the inability to unroll the coil, and achieve the effect of less reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

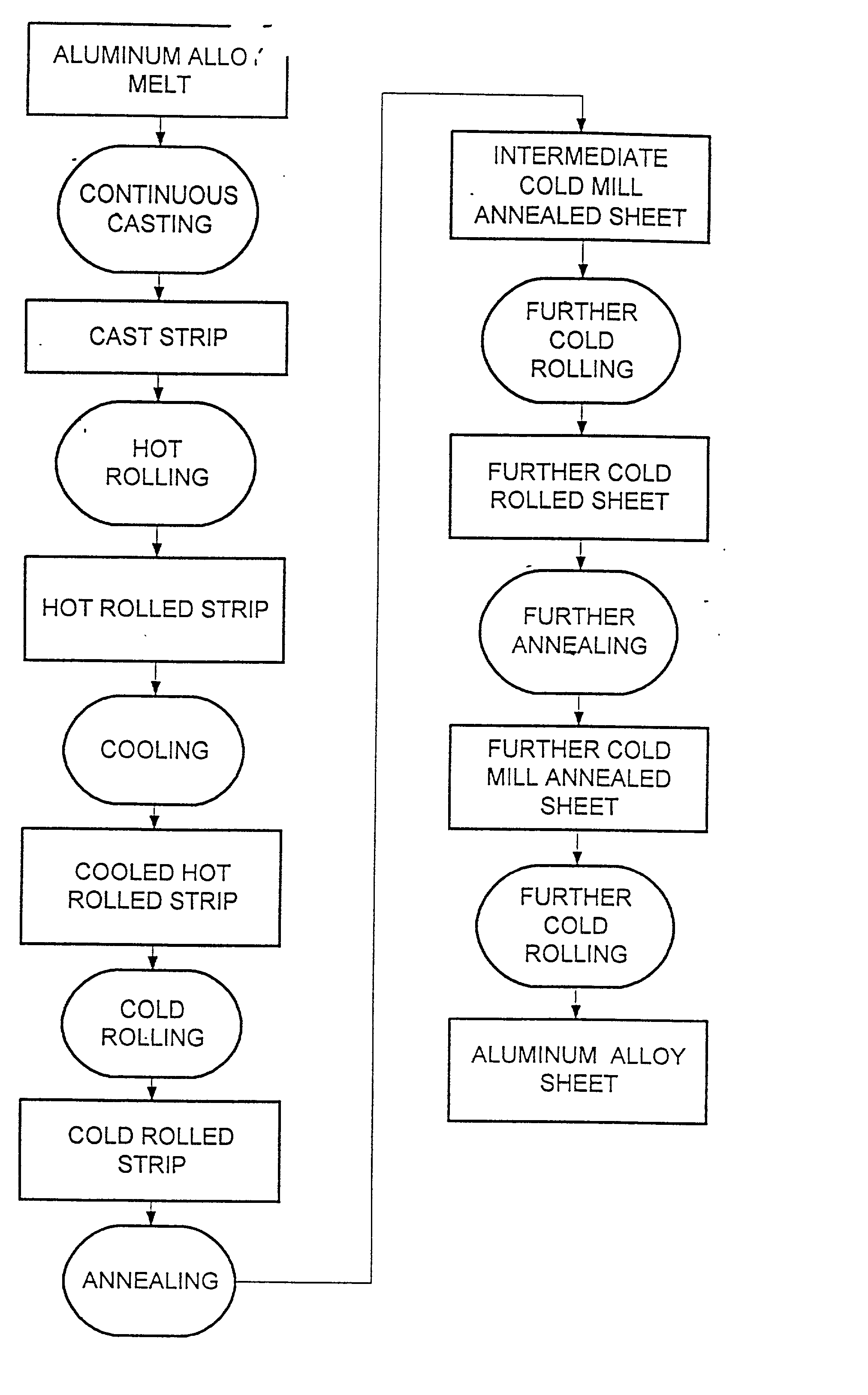

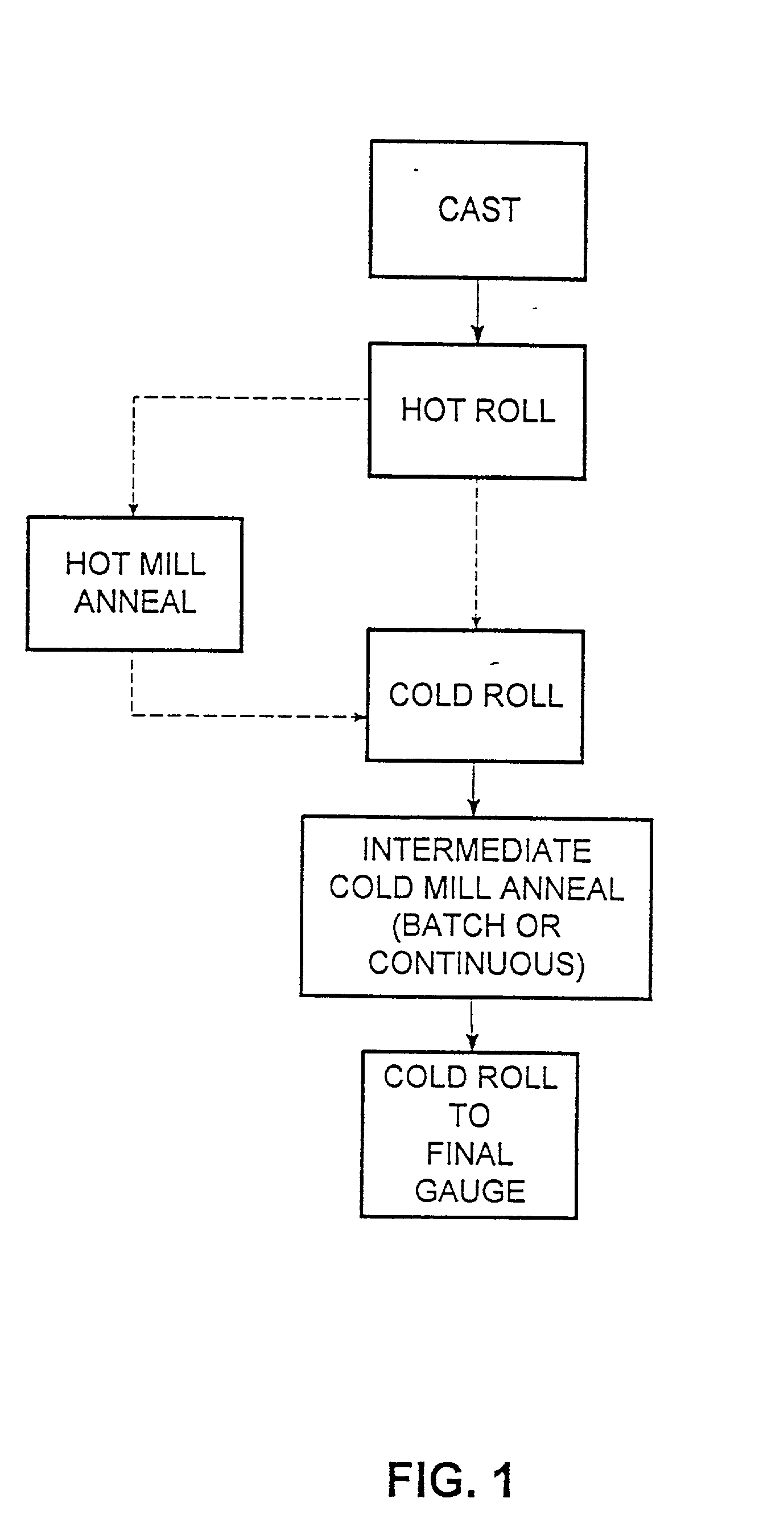

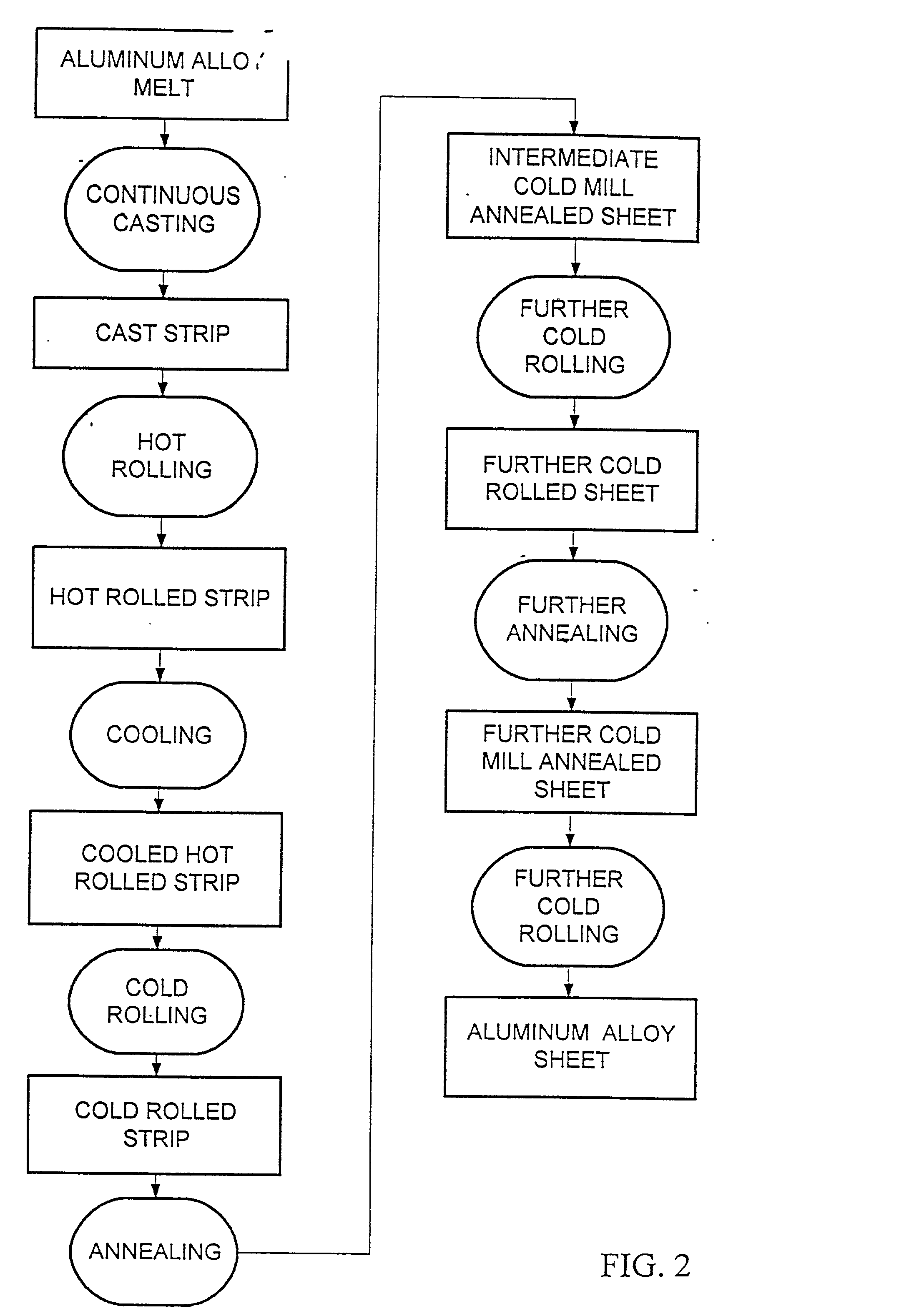

Method used

Image

Examples

examples 1-10

[0091] In order to illustrate the advantages of the present invention, a number of aluminum alloys were formed into sheets.

[0092] Four examples comparing AA 3004 / 3104 alloys with the alloys of the present invention are illustrated in Table I.

1 TABLE I Composition Hot mill Cold mill (weight %) Anneal Anneal Secondary Example Mg Mn Cu Fe Temperature Temperature Cold Work 1 (comparative) 1.21 0.84 0.22 0.44 825.degree. F. 705.degree. F. 75% 2 (comparative) 1.28 0.96 0.21 0.41 825.degree. F. 705.degree. F. 75% 3 1.22 0.83 0.42 0.35 825.degree. F. 705.degree. F. 64% 4 1.31 0.99 0.41 0.34 825.degree. F. 705.degree. F. 61%

[0093] In each example, the silicon content was between 0.18 and 0.22 and the balance of the composition was aluminum. Each alloy was continuously cast in a block caster and was then continuously hot rolled. The hot mill and intermediate cold mill anneals were each for about 3 hours. After the hot mill anneal; the sheets were cold rolled to reduce the thickness by from ab...

examples 11-19

[0108] To illustrate the advantages of aluminum alloy sheet of the present invention relative to aluminum alloy sheet produced by other continuous casting and ingot casting processes, a number of aluminum alloys were formed into sheets. In the tests, six samples of 3000 series alloys produced by other continuous casting or ingot casting processes were compared with three 3000 series alloys produced according to the method of the present invention. The results are presented in Tables VI (A) and (B).

6 TABLE VI(A) Alloy Composition As rolled After Bake Sample # Designation Si Cu Fe Mn Mg UTS YTS Elong. Earing % UTS YTS EL 11 5349D 0.38 0.43 0.28 1.14 1.81 42.8 39.5 3.2 1.4 42.5 37.2 5.6 12 3304B 0.19 0.37 0.41 0.81 1.2 42.3 38.8 4.1 1.7 42.3 37.1 5.1 13 3304C 0.21 0.55 0.41 1.04 1.3 43.9 39.9 4.4 1.8 43.1 37.8 5.3 14 3304F 0.21 0.55 0.41 0.83 1.36 43.3 39.1 4.4 1.8 42.6 37.3 5.3 15 3304CSV 0.38 0.57 0.47 1.05 1.33 43.5 40.1 4.59 2.6 43.3 37.6 5.87 16 3304C5V(mod) 0.38 0.57 0.46 1.04 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com