Carriage band sawing machine body with self-cleaning function

A self-cleaning, machine bed technology, applied in band saws, manufacturing tools, sawing equipment, etc., can solve the problems of easily polluted and corroded tracks and walking wheels, increased bed resistance, inconvenient cleaning, etc., and achieves simple structure, operation and use. Convenience and hygienic production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

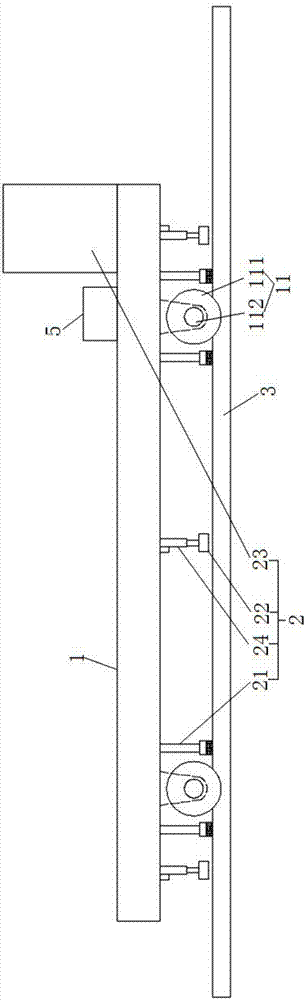

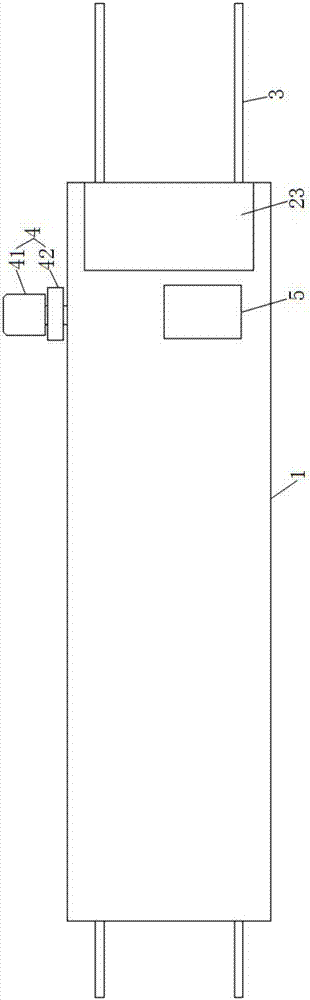

[0031] Example: such as figure 1 and 2 As shown, the body of the sports car band saw machine with self-cleaning function in this embodiment includes a bed frame 1 and a cleaning mechanism 2;

[0032] The front and rear sides of the lower end of the above-mentioned bed frame 1 are respectively provided with traveling wheel sets 11 which can be rotated laterally;

[0033] There are two rails 3 arranged parallel to each other under the bed frame 1;

[0034] The travel wheels 111 at both ends of each of the above-mentioned travel wheel sets 11 are respectively rotatably installed on the two above-mentioned rails 3;

[0035] One of the above-mentioned walking wheel sets 11 is transmission-connected to the driving mechanism 4 for driving its rotation;

[0036] The above-mentioned cleaning mechanism 2 is installed on the above-mentioned bed frame 1, and is used for respectively removing the sawdust adhering to the two above-mentioned rails 3 during the sawing process.

[0037] Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com